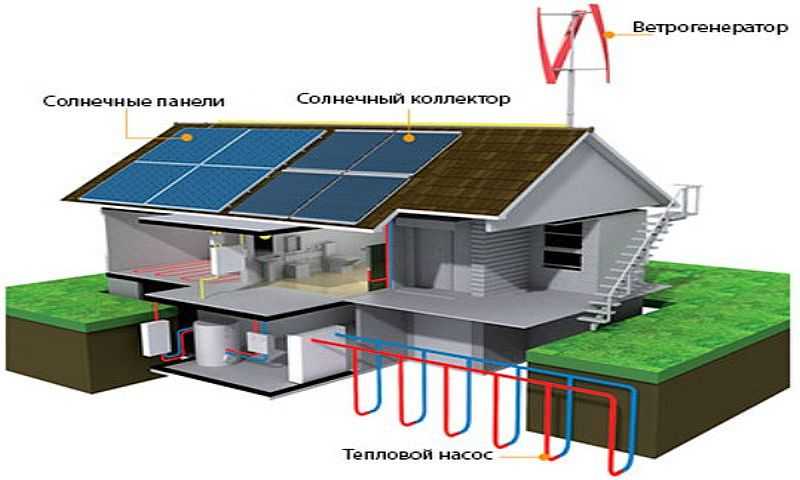

For owners of private houses, there is an opportunity to significantly reduce utility bills or not use the services of heat, electricity and gas providers at all. You can even provide a considerable economy, and if you wish, you can sell the surplus. This is real and some have already done it. For this, alternative energy sources are used.

Where can you get energy and in what form

In fact, energy, in one form or another, is practically everywhere in nature - the sun, wind, water, earth - there is energy everywhere. The main task is to extract it from there. Humanity has been doing this for more than one hundred years and has achieved good results. At the moment, alternative energy sources can provide the house with heat, electricity, gas, warm water. Moreover, alternative energy does not require any super skills or super knowledge. Everything can be done for your home with your own hands. So what can be done:

All alternative energy sources are able to fully meet human needs, but this requires too large investments and/or too large areas. Therefore, it is more reasonable to make a combined system: to receive energy from alternative sources, and if there is a shortage, “to get” from centralized networks.

Use of solar energy

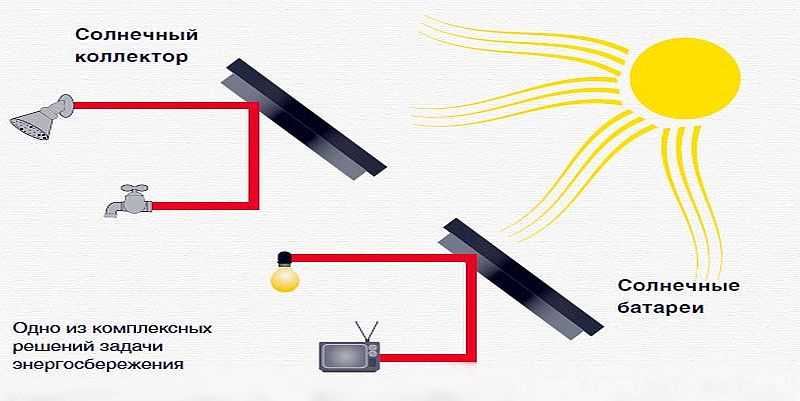

One of the most powerful alternative energy sources for the home is solar radiation. There are two types of installations for converting solar energy:

Do not think that installations work only in the south and only in summer. They work well in winter too. In clear weather with snowfall, energy production is only slightly lower than in summer. If your area has a large number of clear days, you can use this technology.

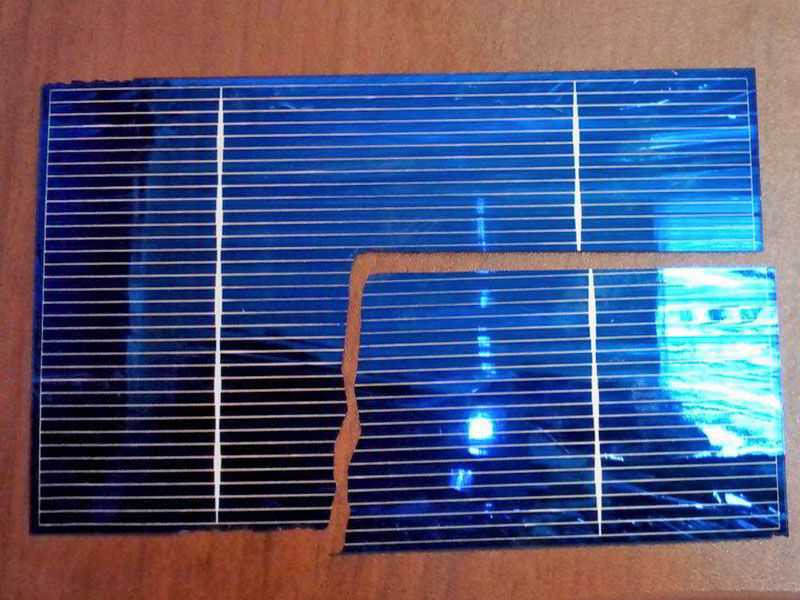

Solar panels

Solar panels are assembled from photovoltaic converters, which are made on the basis of minerals that, under the influence of sunlight, emit electrons - they generate an electric current. For private use, silicon photoconverters are used. In their structure, they are monocrystalline (made from one crystal) and polycrystalline (many crystals). Monocrystalline have a higher efficiency (13-25% depending on the quality) and a longer service life, but are more expensive. Polycrystalline ones generate less electricity (9-15%) and fail faster, but have a lower price.

This is a polycrystalline photoconverter. You need to handle them carefully - they are very fragile (single-crystal too, but not to the same extent)

Assembling a solar battery with your own hands is not difficult. First you need to purchase a certain amount of silicon photocells (the amount depends on the required power). Most often they are bought on Chinese trading platforms such as Aliexpress. Then the procedure is simple:

A few words about why the substrate for the solar panel (batteries) should be painted white. The operating temperature range of silicon wafers is from -40°C to +50°C. Operation at higher or lower temperatures leads to rapid failure of the elements. On the roof, in summer, indoors, the temperature can be much higher than +50°C. That's why white is needed - so as not to overheat the silicon.

Solar collectors

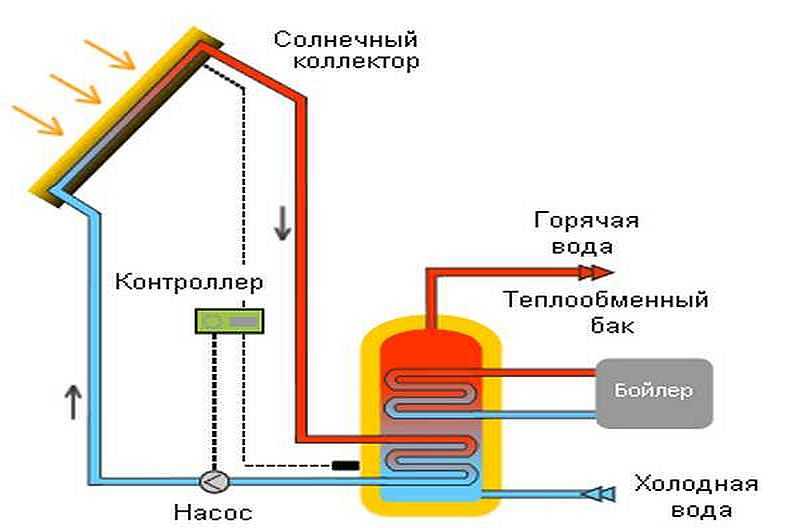

Solar collectors can heat water or air. Where to direct the water heated by the sun - to hot water taps or to the heating system - you choose. Only heating will be low-temperature - for underfloor heating, what is required. But in order for the temperature in the house not to depend on the weather, the system must be made redundant, so that, if necessary, another heat source is connected or the boiler switches to another energy source.

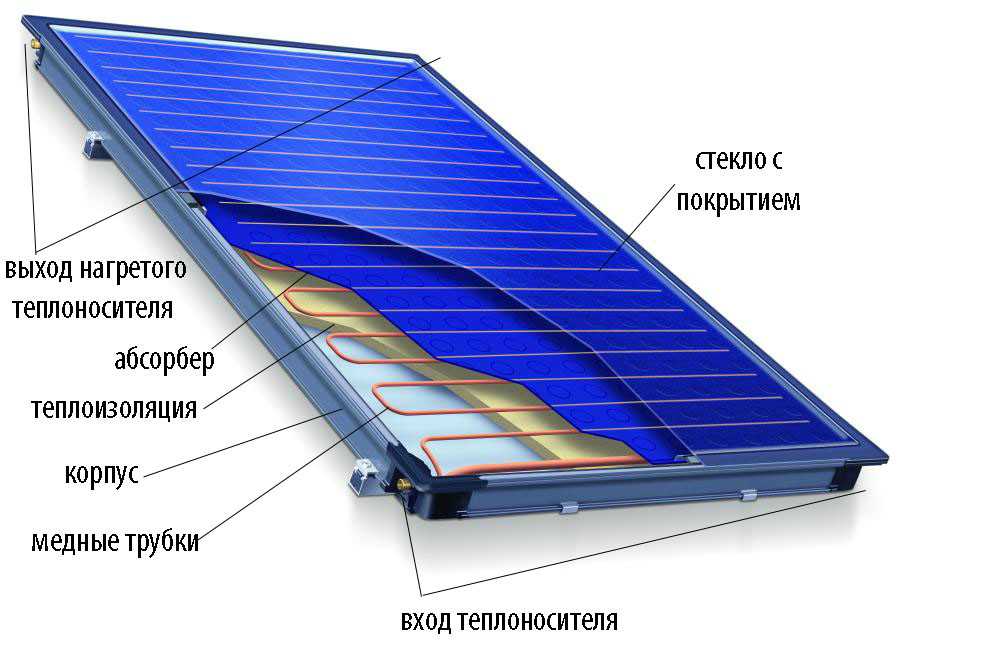

There are three types of solar collectors: flat, tubular and air. The most common are tubular, but others also have a right to exist.

flat plastic

Two panels - black and transparent - are combined into one body. Between them is a copper pipeline in the form of a snake. From the sun, the lower dark panel heats up. copper is heated from it, and from it - the water passing through the labyrinth. This way of using alternative energy sources is not the most efficient, but it is attractive because it is very simple to implement. Thus, you can heat water in. It will only be necessary to loop its supply (using a circulation pump). In the same way, you can heat water in a container for or use it for domestic needs. The disadvantage of such installations is low efficiency and productivity. It takes either a lot of time or a large number of flat-plate collectors to heat a large amount of water.

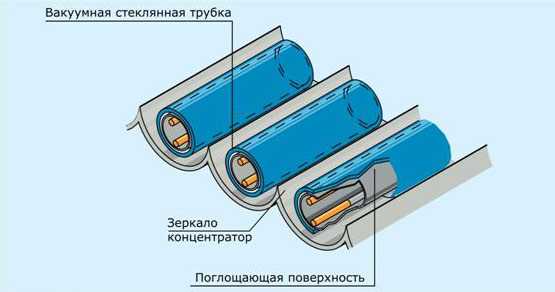

Tubular collectors

These are glass tubes - vacuum or coaxial - through which water flows. A special system allows the maximum concentration in the tubes of heat, which is transferred to the water flowing through them.

The system must have a storage tank in which water is heated. The circulation of water in the system is provided by a pump. Such systems cannot be made independently - it is problematic to make glass tubes with your own hands and this is the main drawback. Together with the high price, it hinders the widespread adoption of this source of energy for the home. And the system itself is very efficient, with a bang it copes with heating water for hot water supply and makes a decent contribution to heating.

Scheme of organizing heating and hot water supply from alternative energy sources - using solar collectors

Air collectors

In our country, they are very rare and in vain. They are simple and easy to make by hand. The only negative is that a large area is required: they can occupy the entire southern (eastern, southeastern) wall. The system is very similar to flat-plate collectors - a black lower panel, a transparent upper one, but they directly heat the air, which is forced (by a fan) or naturally into the room. Despite the seeming frivolity, in this way it is possible to heat small rooms during daylight hours, including technical or utility rooms:, cottages, sheds for living creatures.

Such an alternative source of energy as the sun gives us its heat, but most of it goes "to nowhere". To catch a small fraction of it and use it for personal needs is the task that all these devices solve.

Wind turbines

Alternative energy sources are good because they are mostly renewable resources. The most eternal, probably, is the wind. As long as there is atmosphere and sun, there is also wind. Maybe for a short period the air will be still, but not for long. Our ancestors used wind energy in mills, and modern man converts it into electricity. All that is required for this:

- a tower installed in a windy place;

- generator with blades attached to it;

- storage battery and electric current distribution system.

The tower is built any, from any material. A storage battery is a battery, you can’t imagine anything here, but where to supply electricity is your choice. It remains only to make a generator. It can also be bought ready-made, but it is quite possible to make it from an engine from household appliances - a washing machine, a screwdriver, etc. You will need neodymium magnets and epoxy resin, a lathe.

On the motor rotor we mark the places for the installation of magnets. They must be at an equal distance from each other. We grind the rotor of the selected motor, forming “seats”. The bottom of the recess should have a slight slope so that the surface of the magnet is tilted. Magnets are glued to the carved places on liquid nails, filled with epoxy resin. The surface is then smoothed with sandpaper. Next, you need to attach brushes that will remove the current. And that's it, you can assemble and run a wind generator.

Such installations are quite effective, but their power depends on many factors: wind intensity, how well the generator is made, how effectively the potential difference is removed by brushes, on the reliability of electrical connections, etc.

Heat pumps for home heating

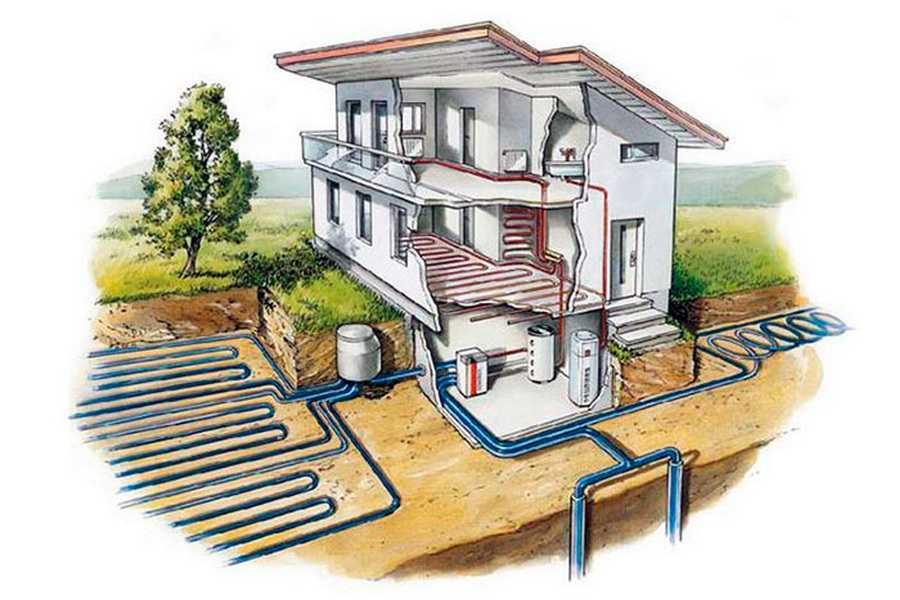

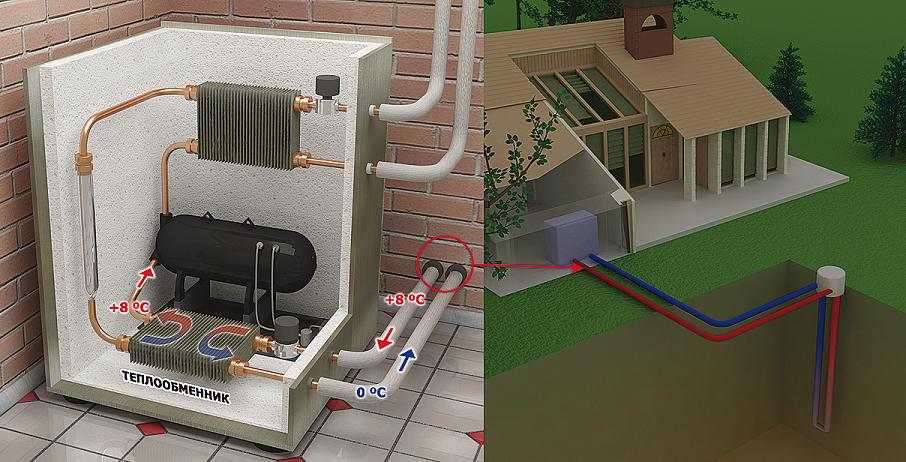

Heat pumps use all available alternative energy sources. They take heat from water, air, soil. In small quantities, this heat is there even in winter, so the heat pump collects it and redirects it to heating the house.

Heat pumps also use alternative energy sources - the heat of the earth, water and air

Principle of operation

Why are heat pumps so attractive? The fact that having spent 1 kW of energy for its pumping, in the worst case, you will receive 1.5 kW of heat, and the most successful implementations can give up to 4-6 kW. And this does not contradict the law of conservation of energy in any way, because energy is spent not on obtaining heat, but not on pumping it. So no inconsistencies.

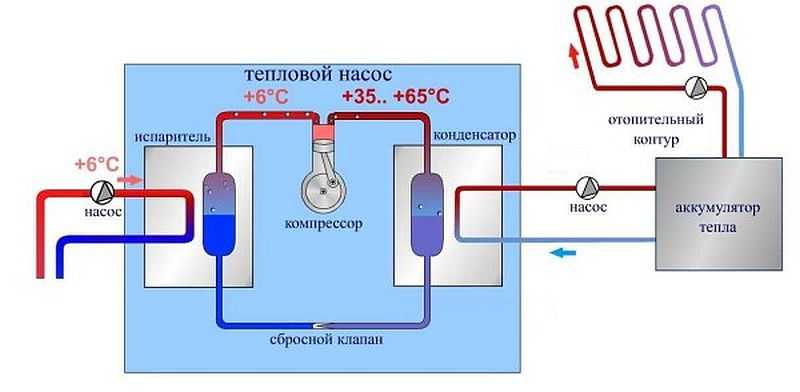

Heat pumps have three working circuits: two external and they are internal, as well as an evaporator, a compressor and a condenser. The scheme works like this:

- A coolant circulates in the primary circuit, which takes heat from low-potential sources. It can be lowered into water, buried in the ground, or it can take heat from the air. The highest temperature reached in this circuit is around 6°C.

- The internal circuit circulates a heating medium with a very low boiling point (typically 0°C). When heated, the refrigerant evaporates, the vapor enters the compressor, where it is compressed to high pressure. During compression, heat is released, the refrigerant vapor is heated to an average temperature of +35°C to +65°C.

- In the condenser, heat is transferred to the coolant from the third - heating - circuit. Cooling vapors are condensed, then further enter the evaporator. And then the cycle repeats.

The heating circuit is best done in the form of a warm floor. Temperatures are the best for this. The radiator system will require too many sections, which is ugly and unprofitable.

Alternative sources of thermal energy: where and how to get heat

But the biggest difficulty is the device of the first external circuit, which collects heat. Since the sources are low-potential (there is little heat at the bottom), large areas are required to collect it in sufficient quantities. There are four types of contours:

- Rings laid in water pipes with a coolant. The body of water can be anything - a river, a pond, a lake. The main condition is that it should not freeze through even in the most severe frosts. Pumps that pump heat out of the river work more efficiently; much less heat is transferred in stagnant water. Such a heat source is the easiest to implement - throw pipes, tie a load. There is only a high chance of accidental damage.

- Thermal fields with pipes buried below freezing depth. In this case, there is only one drawback - large volumes of earthworks. We have to remove the soil over a large area, and even to a solid depth.

- Use of geothermal temperatures. A number of wells of great depth are drilled, and coolant circuits are lowered into them. What is good about this option is that it requires little space, but not everywhere it is possible to drill to great depths, and drilling services cost a lot. It is possible, however, but the work is still not easy.

- Extraction of heat from the air. This is how air conditioners with the possibility of heating work - they take heat from the "outboard" air. Even at sub-zero temperatures, such units work, though at a not very “deep” minus - up to -15 ° C. To make the work more intensive, you can use the heat from the ventilation shafts. Throw a few slings with coolant there and pump heat from there.

The main disadvantage of heat pumps is the high price of the pump itself, and the installation of heat collection fields is not cheap. In this case, you can save money by making the pump yourself and also laying the contours with your own hands, but the amount will still remain considerable. The advantage is that heating will be inexpensive and the system will operate for a long time.

Waste to income:

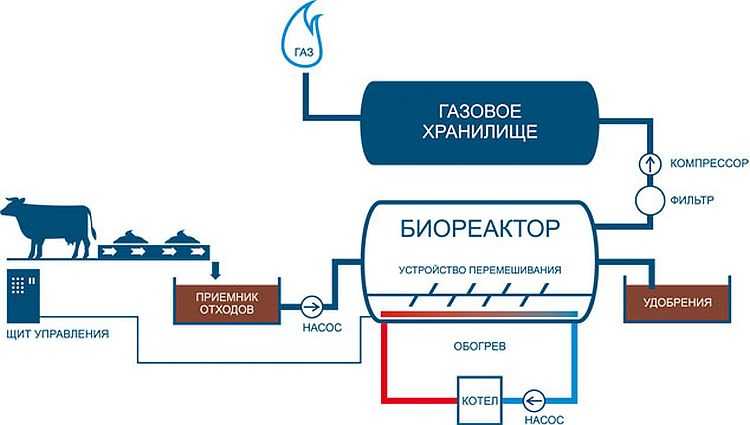

All alternative energy sources are of natural origin, but you can only get a double benefit from biogas plants. They recycle animal and poultry waste. As a result, a certain volume of gas is obtained, which, after purification and drying, can be used for its intended purpose. The remaining processed waste can be sold or used in the fields to increase yields - a very effective and safe fertilizer is obtained.

Briefly about the technology

The formation of gas occurs during fermentation, and bacteria living in manure are involved in this. Any livestock and poultry waste is suitable for biogas production, but cattle manure is optimal. It is even added to the rest of the waste for the "sourdough" - it contains exactly the bacteria needed for processing.

To create optimal conditions, an anaerobic environment is necessary - fermentation must take place without oxygen. Therefore, effective bioreactors are closed containers. In order for the process to proceed more actively, regular mixing of the mass is necessary. In industrial plants, electric mixers are installed for this, in self-made biogas plants, these are usually mechanical devices - from the simplest stick to mechanical mixers that "work" by hand.

There are two types of bacteria involved in the formation of gas from manure: mesophilic and thermophilic. Mesophilic are active at temperatures from +30°C to +40°C, thermophilic - at +42°C to +53°C. Thermophilic bacteria work more efficiently. Under ideal conditions, gas production from 1 liter of usable area can reach 4-4.5 liters of gas. But maintaining a temperature of 50 ° C in the installation is very difficult and costly, although the costs justify themselves.

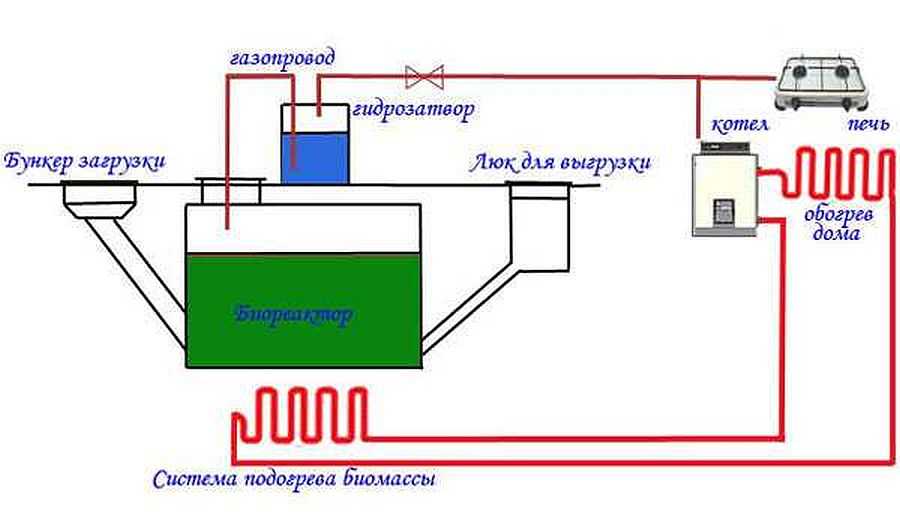

A little about designs

The simplest biogas plant is a barrel with a lid and a stirrer. The lid has an outlet for connecting a hose through which gas enters the tank. You won’t get much gas from such a volume, but it will be enough for one or two gas burners.

More serious volumes can be obtained from an underground or above-ground bunker. If we are talking about an underground bunker, then it is made of reinforced concrete. The walls are separated from the ground with a layer of thermal insulation, the container itself can be divided into several compartments, in which processing will take place with a time shift. Since mesophilic cultures usually work under such conditions, the whole process takes from 12 to 30 days (thermophilic cultures are processed in 3 days), therefore a time shift is desirable.

Manure enters through the loading hopper, on the opposite side they make an unloading hatch, from where processed raw materials are taken. The bunker is not completely filled with biomixture - about 15-20% of the space remains free - gas accumulates here. To drain it, a tube is built into the lid, the second end of which is lowered into a water seal - a container partially filled with water. In this way, the gas is dried - already purified is collected in the upper part, it is discharged using another tube and can already be choked to the consumer.

Anyone can use alternative energy sources. It is more difficult for apartment owners to implement this, but in a private house you can at least implement all the ideas. There are even real examples of that. People fully provide for their needs and considerable economy.