Today, more and more people are moving from city apartments to suburban areas. This is largely due to the fact that the well-being of the townsfolk is growing, opening up new, previously inaccessible opportunities. Yes, and the cost of suburban real estate caught up, and sometimes even became lower than the cost of a good apartment in the city center. This and many other things, as well as the presence of their own vehicles, played a decisive role in the fact that people began to choose peace and solitude, voluntarily refusing such “charms” of city life as drinking neighbors, parking wars, strange people under the windows, and more similar.

The heating system without a circulation pump works by itself, regardless of the presence of electricity in the house.

However, moving to a private house, together with the joy of owning property and fresh air, gives its owner a whole range of tasks that he had absolutely nothing to do with before, entrusting them to special utilities: cleaning the local area, garbage disposal and heating.

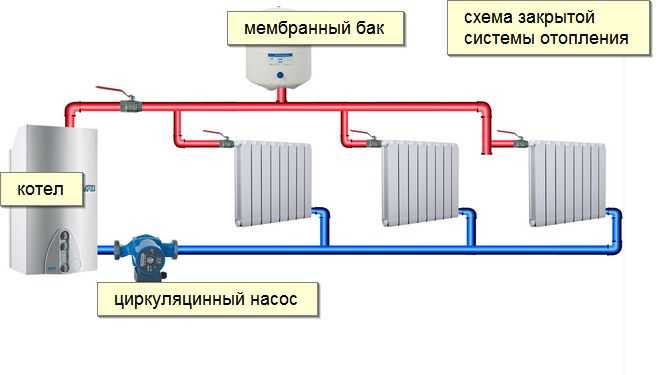

Let's talk about what a closed heating system is, what it consists of and how it works, so that at least one question in the head of a happy landowner becomes less.

Basic principle of operation

First of all, you need to understand what option we are talking about: the heating system without a circulation pump works by itself, regardless of the presence of electricity in the house, this is good, but there is also a drawback - it is the need to pull twice as many pipes and their weak and slow heating. Another thing is a closed-type heating scheme with a circulation pump, which has a huge head start - warming up is much faster, there are more laying possibilities, in a word, there are only pluses. But first things first.

A closed-type heating system with a pump compares favorably with a gravity-flow version in that the movement of the coolant through it is controlled and controlled by a pump.

Without pump

This option is perfect for one-story buildings of a small area. The main advantage of the system is its autonomy. Water, heated in the boiler, rises through the pipes. Then it goes along the horizontal riser, which supplies the coolant to the radiators. From the radiators, the cooled water descends into the lower line leading back to the boiler, and the cycle repeats again.

The pipes are placed at a slight slope, from left to right the top, and from right to left the bottom pipe, through which the cooled coolant is discharged. The expansion tank is installed in this case at the lowest point of the system, its main purpose is to prevent pressure surges and compensate for them. The pressure inside the network is constantly changing dynamically, this is due to the fact that water expands when heated, and contracts when it cools.

The pump will still be needed at the stage of filling the system with water. The pipes are filled until the working pressure is reached, which is, as a rule, one and a half atmospheres.

With pump

A closed-type heating system with a pump compares favorably with a gravity-flow version in that the movement of the coolant through it is controlled and controlled by a pump, which, in turn, allows:

- Choose the piping option that is most suitable for your case;

- Conduct several heating circuits, for example, on the first and second floor separately;

- Regulate the temperature in all rooms without affecting the movement of the coolant and without reducing the performance of the entire system.

Closed heating is best done using a pump. In rare cases, the installation of closed heating without a pump is performed in a hybrid way. The pump is present in such cases, but it is embedded in such a way that in the event of a power outage, the system can switch to autonomous operation. Nevertheless, all the disadvantages of a gravity flow scheme will invariably accompany such a connection.

Pipe routing options

The scheme of a closed heating system with a pump gives several possible options for connecting heating at once.

single pipe

This method can be performed in different ways. Here are the main ways to connect a single-pipe circuit:

- Sequential scheme. At the same time, the coolant moves through the network from radiator to radiator, gradually cooling down, and on the last heating element it almost ceases to do its job;

- Leningradka. So named because it was first developed and implemented in Leningrad. It consists in the fact that the radiators are connected from the bottom side to the riser, which runs horizontally, along the floor or under it. Installing needle valves at the inlet and outlet of the radiator will allow it to be disconnected from the network for repair work, without disturbing the general circulation, and installing an additional valve on the jumper below it will allow you to adjust the pressure and speed of the coolant through the network, achieving the desired temperature.

In addition, there is also the scheme mentioned at the beginning of the article, in which hot water is supplied from above from a riser horizontally located under the ceiling or behind it and, having passed through the radiators, goes back to the pump.

two-pipe

Such a connection makes it possible to achieve a coolant supply to each heating element separately, without loss of pressure, speed and temperature, and the removal is also carried out separately for each radiator. This allows you to install special rheostats on each device, setting the temperature personally for each radiator.

This option is more preferable, since it allows you to configure the thermal control in the building, taking into account the individual needs of each consumer, which gives significant savings in money and resources.

Such a connection makes it possible to achieve a coolant supply to each heating element separately, without loss of pressure, speed and temperature.

Important Details

Regardless of how the connection will be made: with or without a pump, a single-pipe circuit or a two-pipe circuit - there are several units that are mandatory for a closed heating system:

- Boiler. It must be selected according to the operating parameters of the system. Be sure to check the operating pressure range in the boiler - it must meet your requirements;

- Expansion tank of the closed type. Should be equal in volume to one tenth of the capacity of the pipe network. Installed at the lowest point of the system, in front of the pump, if any. The tank compensates for the pressure inside the network and is one of its most important elements. After all, water expands when heated, and when it cools, it contracts - all this causes constant pressure drops inside the pipes. It is the tank that compensates for these differences, take its choice very carefully. Do not confuse - for heating networks, the tank must be red;

- Mayevsky taps on radiators and an automatic air bleed valve installed on a vertical outlet, after the tank, in front of the pipe network. A mandatory element that allows you to remove excess air, which will certainly appear during the operation of the system. Mayevsky's cranes allow air locks to be removed from radiators;

- Pressure gauge and emergency coolant discharge valve. They are placed on a vertical outlet, after the boiler, in front of the main heating network. The pressure gauge allows you to control the pressure inside the pipes, and the valve will come to the rescue if this value goes beyond the permissible limits.

The listed items must be of the highest quality, purchased from authorized representatives of well-known brands and have warranty service. The performance of the entire system depends on them. Do not save on "little things" and your heating will serve you for many years!