Resolution of the State Committee of the Russian Federation

for construction and housing and communal services

On the adoption of building codes and regulations of the Russian Federation

"Labor safety in construction.

Part 2. Construction production"

The State Committee of the Russian Federation for Construction and Housing and Communal Sector decides:

1. Adopt and put into effect from January 1, 2003, the state construction norms and regulations SNiP 12-04-2002 "Labor safety in construction. Part 2. Construction production", presented by the Department of Economics and International Activities of the Gosstroy of Russia, developed by the Federal State Institution " Center for Labor Safety in Construction" of the State Construction Committee of Russia, the Analytical Information Center "Stroitrudobezopasnost", with the participation of the Central Research and Design-Experimental Institute of Organization, Mechanization and Technical Assistance to Construction.

2. To recognize as no longer valid on the territory of the Russian Federation from January 1, 2003, the USSR State Construction Committee Resolution No. 82 dated June 9, 1980 in terms of sections 8-18 SNiP III-4-80* “Safety in construction” with amendments No. 1- 5, as well as GOST 12.3.035-84 "SSBT. Construction. Painting works. Safety requirements", GOST 12.3.038-85 "SSBT. Construction. Work on thermal insulation of equipment and pipelines. Safety requirements" and GOST 12.3.040- 86 "SSBT. Construction. Roofing and waterproofing works. Safety requirements."

Chairman A. Shamuzafarov

Construction codes and regulations of the Russian Federation

OCCUPATIONAL SAFETY IN CONSTRUCTION

Part 2. CONSTRUCTION PRODUCTION

SNiP 12-04-2002

Date of introduction 2003-01-01

PREFACE

1 DEVELOPED by the Federal State Institution “Center for Occupational Safety and Health in Construction” of the Gosstroy of Russia (FGU TSOTS), the Analytical Information Center “Stroytrudobezopasnost” (AITs STB) with the participation of the Central Research and Design Experimental Institute of Organization, Mechanization and Technical Assistance to Construction (AOZT “ TsNIIOMTP")

INTRODUCED by the Department of Economics and International Activities of the Gosstroy of Russia

2. ADOPTED AND ENTERED INTO EFFECT from 01/01/2003 by Resolution of the State Construction Committee of Russia dated 09/17/2002 No. 123

3 INSTEAD of sections 8-18 SNiP III-4-80*, GOST 12.3.035-84, GOST 12.3.038-85, GOST 12.3.040-86

AGREED: Ministry of Labor of Russia (letter dated 03/03/2002 No. 5981-VYA)

FNPR (letter dated June 20, 2002 No. 109-85)

Registered by the Ministry of Justice of Russia on October 18, 2002 No. 3880

1 area of use

These rules and regulations apply to the production of general construction and special construction work performed during new construction, expansion, reconstruction, technical re-equipment, major repairs of buildings and structures (hereinafter referred to as construction production).

These rules and regulations use references to the regulatory legal acts given in Appendix A.

3. General provisions

3.1 The organization and performance of work in construction production must be carried out in compliance with the requirements of SNiP 12-03, PB 10-382 and other regulatory legal acts given in Appendix A, as well as these rules and regulations.

3.2 During the construction of facilities, measures must be taken to prevent workers from being exposed to hazardous and harmful production factors. If they exist, labor safety should be ensured on the basis of decisions contained in the organizational and technological documentation (POS, PPR, etc.), on the composition and content of the relevant requirements of SNiP 12-03 and these rules and regulations.

3.3 Before the start of construction of the facility, the general contractor must carry out preparatory work on organizing the construction site necessary to ensure construction safety, including:

arrangement of fencing of the construction site during the construction of an object in a populated area or on the territory of an organization;

clearing the construction site for the construction of the facility (clearing the area, demolishing buildings), planning the territory, drainage (if necessary, lowering the groundwater level) and relaying communications;

construction of temporary roads, laying temporary power supply networks, lighting, water supply;

delivery and placement on the construction site or outside of it of inventory of sanitary, industrial and administrative buildings and structures;

arrangement of crane tracks, storage areas for materials and structures.

The completion of preparatory work must be accepted according to the act on the implementation of occupational safety measures, drawn up in accordance with SNiP 12-03.

3.4 Work at the construction site should be carried out in technological sequence in accordance with the calendar plan (schedule) of work contained in the PIC. Completion of previous work is a necessary condition for the preparation and implementation of subsequent work.

If it is necessary to combine work, additional measures must be taken to ensure the safety of performing combined work.

3.5 Construction and installation work on the territory of an operating enterprise or a facility under construction must be carried out while carrying out the activities provided for by the approval certificate, the registration of which should be carried out in accordance with SNiP 12-03.

These measures are taken on the basis of decisions developed in the PIC and PPR, and include:

establishing the boundaries of the territory allocated to the contractor for work;

determining the procedure for admitting contractor employees to the organization’s territory;

carrying out the necessary preparatory work on the allocated territory;

determination of the area of combined work and the procedure for performing work there.

3.6 When several contractors, including citizens engaged in self-employment, work together at a construction site, the general contractor monitors the state of working conditions at the construction site.

If dangerous conditions arise at the site that pose a real threat to the life and health of workers, the general contractor must notify all construction participants about this and take the necessary measures to remove people from the danger zone. The resumption of work is permitted by the general contractor after the causes of the danger have been eliminated.

4. Dismantling of buildings and structures during their reconstruction or demolition

4.1 Organization of work

4.1.1 When dismantling buildings and structures (hereinafter referred to as dismantling buildings) during their reconstruction or demolition, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

spontaneous collapse of structural elements of buildings and the fall of overlying unsecured structures, materials, and equipment;

moving parts of construction machines, objects moved by them;

sharp edges, corners, protruding pins;

increased content of dust and harmful substances in the air of the working area;

location of the workplace near a height difference of 1.3 m or more.

4.1.2 Before starting work on dismantling buildings, it is necessary to carry out preparatory measures related to the resettlement of citizens living in them or the departure of organizations located there, as well as disconnection from the networks of water, heat, gas and electricity, sewerage, technological product pipelines and taking measures against their damage.

All necessary approvals for preparatory activities must be made at the stage of developing the PIC.

4.1.3 The dismantling of buildings must be carried out on the basis of the solutions provided for in the organizational and technological documentation (POS, PPR, etc.). These solutions should be developed after conducting an examination of the general condition of the building (structure), as well as foundations, walls, columns, vaults and other structures. Based on the results of the survey, an act is drawn up, on the basis of which the following issues are resolved:

choosing a disassembly method;

establishing hazardous areas and using protective barriers if necessary;

temporary or permanent fastening or strengthening of the structures of a building being dismantled in order to prevent accidental collapse of structures;

dust suppression measures;

safety measures when working at height;

slinging diagrams for dismantling structures and equipment.

4.1.4 Before starting work, it is necessary to familiarize workers with the solutions provided for in the PPR and provide instructions on safe work methods.

Removal of unstable structures during building dismantling should be carried out in the presence of the work supervisor.

4.1.5 When dismantling buildings, access to them by unauthorized persons not involved in the work is prohibited. Work areas for dismantling buildings must be fenced in accordance with SNiP 12-03.

The passage of people into the premises during disassembly must be closed.

4.1.6 When dismantling buildings using a mechanized method, it is necessary to establish zones dangerous for people, and place machines (mechanisms) outside the zone of collapse of structures.

The driver's cabin must be protected from possible debris, and workers must be provided with safety glasses.

4.1.7 When dismantling buildings, as well as when removing waste and debris, it is necessary to take measures to reduce dust formation.

Those working in dusty conditions must be provided with respiratory protection against airborne dust and microorganisms (mold, fungi, their spores).

4.1.8 Before allowing workers into places with the possible appearance of gas or harmful substances, they must be ventilated. If gas appears unexpectedly, work should be stopped and workers should be removed from the danger zone.

Those working in places where gas may appear must be provided with protective equipment (gas masks).

4.2 Work procedure

4.2.1 Dismantling of buildings (dismantling of structures) must be carried out sequentially from top to bottom.

It is prohibited to dismantle buildings simultaneously in several tiers along the same vertical.

4.2.2 When dismantling buildings, it is necessary to leave passages to workplaces.

When dismantling the roof and external walls, workers must use a safety belt.

4.2.3 When dismantling cornices and hanging parts of the building, it is prohibited to stand on the wall.

It is not allowed to carry out work during ice, fog, rain that excludes visibility within the work front, thunderstorms and wind at a speed of 15 m/s or more.

4.2.4 When dismantling buildings, it is necessary to prevent spontaneous collapse or falling of structures.

Unstable structures located in the work area should be removed or secured, or strengthened in accordance with the PPR.

It is prohibited to cut chimneys, stone pillars and walls manually, or to collapse them onto the ceiling.

4.2.5 When dismantling buildings using the “felling” method, the length of the attached cables (ropes) must be 3 times the height of the building.

4.2.6 When dismantling buildings by explosive means, it is necessary to comply with the requirements of PB 13-407.

4.2.7 When dismantling structures and equipment using load-lifting cranes, it is necessary to comply with the requirements of Section 8 of these rules and regulations.

Methods of release, as well as slinging schemes for dismantled structures must comply with those provided for in the PPR.

4.2.8 Materials obtained from the dismantling of buildings, as well as construction waste, must be lowered through closed chutes or in closed boxes or containers using lifting cranes. The bottom end of the chute should be no higher than 1 m above the ground or enter the bunker.

Disposing of waste without chutes or other devices is permitted from a height of no more than 3 m. Dangerous areas in these places must be fenced off. The dimensions of the danger zone are established in accordance with SNiP 12-03.

4.2.9 Materials obtained during the dismantling of buildings must be stored in specially designated areas.

5. Excavation work

5.1 Organization of work

5.1.1 When performing excavation and other work related to placing workplaces in excavations and trenches, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

falling objects (pieces of rock);

moving machines and their working parts, as well as objects moved by them;

location of the workplace near a height difference of 1.3 m or more;

increased voltage in an electrical circuit, the closure of which can occur through the human body;

chemically hazardous and harmful production factors.

5.1.2 In the presence of dangerous and harmful production factors specified in 5.1.1, the safety of excavation work must be ensured based on the implementation of the following labor protection decisions contained in the organizational and technological documentation (POS, PPR, etc.):

determination of the safe steepness of loose slopes of pits, trenches (hereinafter referred to as excavations), taking into account the load from machines and soil;

determination of the design of fastening the walls of pits and trenches;

selection of types of machines used for soil development and places of their installation;

additional measures to control and ensure slope stability due to seasonal changes;

determination of installation locations and types of fencing for pits and trenches, as well as stairs for descending workers to the work site.

5.1.3 In order to prevent soil erosion, the formation of landslides, and the collapse of the walls of excavations in places where excavation works are carried out, it is necessary to ensure the drainage of surface and groundwater before they begin.

The work site must be cleared of boulders, trees, and construction debris.

5.1.4 Excavation work in the security zone of high-voltage cables, an existing gas pipeline, other communications, as well as in areas with possible pathogenic contamination of the soil (landfills, cattle burial grounds, cemetery, etc.) must be carried out according to a permit after obtaining permission from the organization operating these communications or the sanitary inspection authority.

Work under these conditions should be carried out under the direct supervision of the work manager, and in the security zone of live cables or existing gas pipelines, in addition, under the supervision of employees of organizations operating these communications.

5.1.5 Development of soil in the immediate vicinity of existing underground communications is permitted only with the help of shovels, without the use of impact tools.

The use of earth-moving machines at the intersection of excavations with existing communications that are not protected from mechanical damage is permitted in agreement with the organizations that own the communications.

5.1.6 If communications, underground structures or explosive materials not specified in the project are discovered during excavation work, the excavation work must be suspended until permission from the relevant authorities is obtained.

5.2 Organization of workplaces

5.2.1 When placing workplaces in excavations, their dimensions, adopted in the design, must ensure the placement of structures, equipment, accessories, as well as passages at workplaces and to workplaces with a clear width of at least 0.6 m, and at workplaces - also the required space in the work area.

5.2.2 Excavations excavated on streets, driveways, in courtyards of populated areas, as well as in other places where people may be present, must be fenced with protective fences taking into account the requirements of state standards. Warning signs must be installed on the fence, and warning lights must be installed at night.

5.2.3 For the passage of people through excavations, transition bridges must be constructed in accordance with the requirements of SNiP 12-03.

To access work places in excavations, ladders or flight ladders with a width of at least 0.6 m with guardrails or ladders (wooden - no more than 5 m long) should be installed.

5.2.4 Work involving the presence of workers in excavations with vertical walls without fastening in sandy, silty-clayey and thawed soils above the groundwater level and in the absence of underground structures near them is allowed at their depth of no more than, m:

1.0 - in non-compacted bulk and natural sandy soils;

1.25 - in sandy loams;

1.5 - in loams and clays.

5.2.5 When the average daily air temperature is below minus 2C, it is allowed to increase the maximum depth of the vertical walls of excavations in frozen soils, except for loose frozen soils, compared to the value established in 5.2.4 by the depth of soil freezing, but not more than 2 m.

5.2.6 Work involving the presence of workers in excavations with slopes without fastenings in bulk, sandy and silty-clayey soils above the groundwater level (taking into account capillary rise) or soils drained by artificial dewatering is permitted depending on the depth of the excavation and the steepness slopes indicated in table 1.

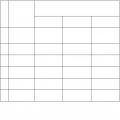

Table 1

Item No. Types of soils Slope steepness (ratio of its height to foundation) at excavation depth, m, no more

1,5 3,0 5,0

1. Bulk uncompacted 1:0.67 1:1 1:1.25

2. Sand 1:0.5 1:1 1:1

3. Sandy loam 1:0.25 1:0.67 1:0.85

4. Loam 1:0 1:0.5 1:0.75

5. Clay 1:0 1:0.25 1:0.5

6. Loess 1:0 1:0.5 1:0.5

Notes: 1. When layering different types of soil, the steepness of the slopes is assigned according to the least resistant type from slope collapse;

2. Non-compacted fill soils include soils with a filling period of up to two years for sandy soils; up to five years - for silty-clayey soils.

5.2.7 The steepness of slopes of excavations with a depth of more than 5 m in all cases and a depth of less than 5 m under hydrological conditions and types of soil not provided for in 5.2.12, as well as slopes subject to moisture, must be established by the design.

5.2.8 The design of fastening the vertical walls of excavations up to 3 m deep in soils of natural moisture should, as a rule, be made according to standard designs. In case of greater depth, as well as complex hydrogeological conditions, the fastening must be carried out according to an individual project.

5.2.9 When installing fasteners, their upper part must protrude above the edge of the recess by at least 15 cm.

5.2.10 Before allowing workers into excavations with a depth of more than 1.3 m, the responsible person must check the condition of the slopes, as well as the reliability of fastening the walls of the excavation.

Boulders and stones, as well as loose soil found on slopes, must be removed.

5.2.11 The admission of workers into excavations with slopes that have been wetted is permitted only after a thorough inspection by the person responsible for ensuring the safety of the work, the condition of the soil of the slopes and the collapse of unstable soil in places where “peaks” or cracks (delaminations) are found.

5.2.12 Excavations developed in winter must be inspected upon the onset of a thaw, and based on the inspection results, measures must be taken to ensure the stability of the slopes and fastenings.

5.2.13 The development of excavations with vertical walls without fastening by rotary and trench excavators in cohesive soils (loams and clays) is allowed to a depth of no more than 3 m. In places where workers are required, fastenings must be installed or slopes developed.

When extracting soil from excavations using buckets, it is necessary to install protective canopies to protect those working in the excavation.

5.3 Work procedure

5.3.1 It is necessary to install fasteners in the direction from top to bottom as the excavation is developed to a depth of no more than 0.5 m.

5.3.2 It is not allowed to excavate soil in excavations. The soil removed from the excavation must be placed at a distance of at least 0.5 m from the edge of this excavation.

5.3.3 When developing excavations in the ground with a single-bucket excavator, the height of the face must be determined by the PPR in such a way that “peaks” of the soil do not form during the work.

5.3.4 When the excavator is operating, it is not allowed to carry out other work from the face and workers are not allowed to be within the radius of the excavator plus 5 m.

5.3.5 Dismantling of fasteners in recesses should be carried out from the bottom up as the recess is backfilled, unless otherwise provided by the PPR.

5.3.6 During mechanical impact loosening of soil, workers are not allowed to be at a distance closer than 5 m from the loosening sites.

5.3.7 One-sided backfilling of cavities during the construction of retaining walls and foundations is permitted in accordance with the PPR after measures have been taken to ensure the stability of the structure, under the accepted conditions, methods and order of backfilling.

5.3.8 When developing, transporting, unloading, leveling and compacting soil with two or more self-propelled or trailed machines (scrapers, graders, rollers, bulldozers), going one after another, the distance between them must be at least 10 m.

5.3.9 When unloading on embankments, as well as when backfilling excavations, dump trucks should be installed no closer than 1 m from the edge of the natural slope; Unloading from overpasses that do not have protective (fender) bars is prohibited.

The unloading locations for vehicles must be determined by the traffic controller.

5.3.10 It is prohibited to develop soil with bulldozers and scrapers when moving uphill or downhill, with an inclination angle greater than that specified in the machine’s passport.

5.3.11 The presence of workers and other persons in areas where soil compaction work is being carried out with free-falling rammers is not allowed, closer than 20 m from the base machine.

5.4 Special work methods

5.4.1 When developing quarries, it is necessary to comply with the requirements of regulatory documents of the Gosgortekhnadzor of Russia.

5.4.2 When developing rocky, frozen earthen soils using explosive methods, it is necessary to comply with the requirements of PB 13-407.

5.4.3 If it is necessary to use machines in difficult conditions (cutting soil on a slope, clearing rubble), you should use machines equipped with protective equipment that prevent workers from being exposed to hazardous production factors that arise in these conditions (falling objects and overturning).

5.4.4 In the case of electrical heating of the soil, the voltage of the power source should not be higher than 380 V.

The heated area of soil must be fenced off, safety signs installed on the fence, and illuminated at night. The distance between the fence and the contour of the heated area must be at least 3 m. Workers and other persons are not allowed to stay in the heated area.

5.4.5 Temporary power supply lines to heated areas of the ground must be made with insulated wire, and after each movement of electrical equipment and relocation of electrical wiring, the insulation resistance should be measured with a megohmmeter.

5.4.6 When developing soil using hydromechanization, the requirements of state standards must be met.

6. Construction of artificial foundations and drilling operations

6.1. Organization of work

6.1.1 When constructing artificial foundations and performing drilling operations, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

collapsing rocks (soils);

moving machines and their working parts, as well as structures and objects they move;

location of workplaces near a height difference of 1.3 m or more;

overturning of cars, falling of piles and their parts;

increased voltage in an electrical circuit, the closure of which can occur through the human body.

6.1.2 In the presence of dangerous and harmful production factors specified in 6.1.1, the safety of the construction of artificial foundations and drilling operations must be ensured based on the implementation of the following labor protection decisions contained in the organizational and technological documentation (POS, PPR, etc.):

determination of methods and selection of mechanization means for carrying out work;

establishing the sequence of work;

development of a scheme for installation and dismantling of equipment, as well as its movement on the site;

determination of the range and required quantity of collective protective equipment necessary for use in the design of machines, as well as in the organization of workplaces.

6.1.3 Drilling operations and work on constructing artificial foundations should be carried out in compliance with the requirements of Section 5 of these rules and regulations.

6.1.4 Pile driving and drilling machines must be equipped with limiters for the lifting height of the drilling tool or load-handling device and an audible alarm.

6.1.5 Ropes must have a manufacturer’s certificate or a test report; lifting equipment must be tested and have tags or stamps confirming their load-carrying capacity and the date of testing.

6.1.6. The maximum weight of the hammer and pile for a pile driver, according to the machine’s passport, must be indicated on its truss or frame.

6.1.7 The distance between installed piling or drilling machines and buildings located near them is determined by the PPR. When operating these machines, a danger zone should be established at a distance of at least 15 m from the wellhead or the place where the pile is driven.

6.1.8 The movement of piling and drilling machines should be carried out along a pre-planned horizontal path when the machine structure is in the transport position.

6.1.9 When driving piles with a floating pile driver, it is necessary to ensure its reliable mooring to anchors fixed on the shore or at the bottom, as well as communication with the shore using duty vessels or a pedestrian bridge.

The floating pile driver must be provided with lifebuoys and a boat.

It is not allowed to carry out piling work on rivers and reservoirs with waves of more than 2 points.

6.1.10 Driving piles from ice is permitted only if there are special measures in the PPR to ensure the strength of the ice cover.

6.1.11 When work is stopped, drilled wells must be covered with shields or fenced. Safety warning signs and signal lighting must be installed on boards and fences.

6.1.12 Vibratory hammers must be equipped with suspended inventory platforms to accommodate workers who are attaching the head of the vibratory hammer to the shell.

The width of the platform deck must be at least 0.8 m. The platform deck must be fenced in accordance with the requirements of SNiP 12-03.

6.1.13 The inside walls of the sink well must be equipped with at least two securely fastened hanging ladders.

6.1.14 It is necessary to install protective canopies along the inner perimeter of the manhole. The dimensions, strength and installation procedure of the canopies must be determined in the PPR.

6.1.15 Premises where solutions for chemical fixation of soil are prepared must be equipped with ventilation and appropriate containers for storing materials.

6.2 Work procedure

6.2.1 Installation, dismantling and movement of piling and drilling machines should be carried out under the direct supervision of persons responsible for the safe performance of the specified work.

Installation, dismantling and movement of piling and drilling machines during winds of 15 m/s or more or thunderstorms are not allowed.

6.2.2 The technical condition of piling and drilling machines (reliability of fastening units, serviceability of connections and working decks) must be checked before the start of each shift.

6.2.3 Before lifting piling or drilling machine structures, their elements must be securely secured, and tools and loose objects must be removed.

When lifting a structure assembled in a horizontal position, all other work must be stopped within a radius equal to the length of the structure plus 5 m.

6.2.4 During the period of operation of piling or drilling machines, persons not directly involved in the performance of these works are not allowed to approach the machines at a distance of less than 15 m.

6.2.5 Before starting drilling or piling work, you must check:

serviceability of sound and light signaling devices, lifting height limiter of the lifting body;

the condition of the ropes for lifting mechanisms, as well as the condition of lifting devices;

serviceability of all mechanisms and metal structures.

6.2.6 Before inspecting, lubricating, cleaning or troubleshooting a drilling machine or pile driver, the drilling tool or pile driving mechanism must be lowered and placed in a stable position, and the engine stopped and turned off.

6.2.7 The lowering and raising of the drilling tool or pile is carried out after giving a warning signal.

While lifting or lowering a drilling tool, it is prohibited to perform work on the copter or drilling machine that is not related to the specified processes.

6.2.8 Lifting the pile (sheet pile) and the pile hammer must be carried out using separate hooks. If there is only one hook on the pile driver for installing the pile, the pile hammer must be removed from the hook and installed on a reliable locking bolt.

When lifting, the pile must be kept from swinging and torsion using braces.

Simultaneous lifting of the piling hammer and the pile is not allowed.

6.2.9 Piles are allowed to be pulled in a straight line within the visibility of the pile driver driver only through a tapping block fixed at the base of the pile driver. It is prohibited to pull piles with a pile driver to a distance of more than 10 m and with their deviation from the longitudinal axis.

6.2.10 When cutting piles driven into the ground, it is necessary to take measures to prevent the part being removed from suddenly falling.

6.2.11 Installation of piles and pile-driving equipment is carried out without interruption until they are completely secured.

Leaving them hanging is not allowed.

6.2.12 When driving piles using vibratory drivers, it is necessary to ensure a tight and reliable connection of the vibratory driver with the pile cap, as well as the free condition of the ropes supporting the vibratory driver.

6.2.13 The vibrator should be turned on only after it has been secured to the pile and the supporting pulleys have been loosened. The weakened state of the pulleys must be maintained throughout the entire operating time of the vibrator.

The vibrator should be turned off during every break in work.

6.2.14 When immersing shell piles, workers’ access to the suspended platform for attaching the head of a vibratory driver or the next section of the shell pile to the immersed shell pile is permitted only after the supplied structure has been lowered by a crane to a distance of no more than 30 cm from the top of the immersed shell pile. .

6.2.15 The sequence of soil development under the edge of the knife of the drop well should ensure its stability. The depth of soil development from the edge of the well knife is determined according to the PPR.

It is not allowed to develop soil below 1 m from the edge of the well knife.

6.2.16 When developing mobile soils with drainage or if there is a layer of such soils above the well blade, measures must be taken to ensure rapid evacuation of people in the event of a sudden breakthrough of the soil and flooding of the well.

6.2.17 Equipment and pipelines intended for performing work on soil freezing must be tested:

freezing station devices after installation - with pneumatic or hydraulic pressure specified in the passport, but not less than 1.2 MPa for the suction side and 1.8 MPa for the discharge side;

freezing columns before lowering into wells - with hydraulic pressure of at least 2.5 MPa.

6.2.18 Construction work in the area of artificial soil consolidation by freezing is permitted only after the ice-soil barrier reaches its designed thickness. Permission to carry out work must be formalized in an act.

6.2.19 Extracting soil from a pit that has an ice-soil barrier is permitted if the frozen wall is protected from rain and sunlight. When working, precautions should be taken to protect the ice-ground fencing from mechanical damage.

6.2.20 The procedure for monitoring the size and temperature of the ice-soil fencing of the pit during the process of freezing and thawing of the soil must be determined by the design.

6.2.21 Pipelines, hoses and injectors used for injection work on chemical consolidation of soils (silicatization, etc.) must be subjected to hydraulic tests with a pressure equal to one and a half working values, but not lower than 0.5 MPa.

6.2.22 Autoclave-type silicate cookers and other devices that are under pressure during operation must be subjected to regular technical inspections and periodic hydraulic tests in accordance with the requirements of the Gosgortekhnadzor of Russia.

... The full version of the document with tables, images and applications is in the attached file...

11 To prevent electric shock to workers, the following should be provided:

- instructions for the construction of temporary electrical installations, the selection of routes and determination of the voltage of temporary power and lighting electrical networks, devices for fencing live parts and the location of input distribution systems and devices;

- methods of grounding metal parts of electrical equipment;

- additional protective measures when performing work in high-risk and especially dangerous areas,

A also when performing work in similar conditions outdoors;

- measures for the safe performance of work in security zones and power lines.

12 To prevent workers from being exposed to harmful production factors (unfavorable microclimate, noise, vibration, dust and harmful substances in the air of the working area), it is necessary:

- identify areas of work where harmful production factors caused by technology may arise

And work conditions;

- determine means of protection for workers;

- provide, if necessary, special measures for the storage of hazardous and harmful substances.

13 Provide the necessary protective measures when using devices containing radioactive isotopes and serving as sources of ionizing radiation, as well as when using lasers.

SNiP 12-04-2002 “Labor safety in construction. Part 2 Construction production"

1 AREA OF USE

Regulatory documentation database: www.complexdoc.ru

These rules and regulations apply to the production of general construction and special construction work performed during new construction, expansion, reconstruction, technical re-equipment, major repairs of buildings and structures (hereinafter referred to as construction production).

IN These rules and regulations use references to regulatory legal acts given in the appendix A .

3. GENERAL PROVISIONS

3.1 The organization and execution of work in construction production must be carried out in compliance with the requirements SNiP 12-03, PB 10-382 and other regulatory legal acts given in Appendix A, as well as these rules and regulations.

3.2 During the construction of facilities, measures must be taken to prevent workers from being exposed to hazardous and harmful production factors. If they exist, labor safety must be ensured on the basis of the decisions contained in organizational and technological documentation (POS, PPR, etc.), on the composition and content of the relevant requirements of SNiP 12-03, these rules and regulations and other regulatory documents.

3.3 Before the start of construction of the facility, the general contractor must carry out preparatory work on organizing the construction site necessary to ensure construction safety, including:

- arrangement of fencing of the construction site during the construction of an object in a populated area or on the territory of an organization;

- clearing the construction site for the construction of the facility (clearing the area, demolishing buildings), planning the territory, drainage (if necessary, lowering the groundwater level) and relaying communications;

- construction of temporary roads, laying temporary power supply networks, lighting, water supply;

Regulatory documentation database: www.complexdoc.ru

- delivery and placement on the construction site or outside of it of inventory sanitary, industrial and administrative buildings and structures;

- arrangement of crane tracks, storage areas for materials

And designs. The completion of preparatory work must be accepted according to the completion certificate

occupational safety measures, formalized in accordance with SNiP 12-03.

3.4 Work at a construction site should be carried out

V technological sequence according to the contents

V POS calendar plan (schedule) of work. Completion of previous work is a necessary condition for the preparation and implementation of subsequent work.

If it is necessary to combine work, additional measures must be taken to ensure the safety of performing combined work.

3.5 Construction and installation work on the territory of an operating enterprise or a facility under construction must be carried out while carrying out the activities provided for by the approval certificate, the registration of which should be carried out in accordance with SNiP 12-03.

These measures are taken on the basis of decisions developed in the PIC and PPR, and include:

- establishing the boundaries of the territory allocated to the contractor for work;

- determining the procedure for admitting contractor employees to the organization’s territory;

- carrying out the necessary preparatory work on the allocated territory;

- determination of the area of combined work and the procedure for performing work there.

3.6 When several contractors, including citizens engaged in self-employment, work together at a construction site,

Regulatory documentation database: www.complexdoc.ru

The general contractor monitors the working conditions at the construction site.

If dangerous conditions arise at the site that pose a real threat to the life and health of workers, the general contractor must notify all construction participants about this and take the necessary measures to remove people from the danger zone. The resumption of work is permitted by the general contractor after the causes of the danger have been eliminated.

4. DISASSEMBLY OF BUILDINGS AND STRUCTURES DURING THEIR RECONSTRUCTION OR DEMOLITION

4.1 Organization of work

4.1.1 When dismantling buildings and structures (hereinafter referred to as dismantling buildings) during their reconstruction or demolition, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

- spontaneous collapse of structural elements of buildings

And fall of overlying unsecured structures, materials, equipment;

- moving parts of construction machines, objects moved by them;

- sharp edges, corners, protruding pins;

- increased content of dust and harmful substances in the air of the working area;

and more.

4.1.2 Before starting work on dismantling buildings, it is necessary to carry out preparatory measures related to the resettlement of citizens living in them or the departure of organizations located there, as well as disconnection from the networks of water, heat, gas and electricity, sewerage, technological product pipelines and taking measures against their damage.

Regulatory documentation database: www.complexdoc.ru

All necessary approvals for preparatory activities must be made at the stage of developing the PIC.

4.1.3 The dismantling of buildings must be carried out on the basis of the solutions provided for in the organizational and technological documentation (POS, PPR, etc.). These solutions should be developed after conducting an examination of the general condition of the building (structure), as well as foundations, walls, columns, vaults and other structures. Based on the results of the survey, an act is drawn up, on the basis of which the following issues are resolved:

- choosing a disassembly method;

- establishing hazardous areas and using protective barriers if necessary;

- temporary or permanent fastening or strengthening of the structures of a building being dismantled in order to prevent accidental collapse of structures;

- dust suppression measures;

- safety measures when working at height;

- slinging diagrams for dismantling structures and equipment.

4.1.4 Before starting work, it is necessary to familiarize workers

With solutions provided for in the PPR, and provide instructions on safe work methods.

Removal of unstable structures during building dismantling should be carried out in the presence of the work supervisor.

4.1.5 When dismantling buildings, access to them by unauthorized persons not involved in the work is prohibited. Work areas for dismantling buildings must be fenced in accordance with SNiP 12-03.

The passage of people into the premises during disassembly must be closed.

Regulatory documentation database: www.complexdoc.ru

4.1.6 When dismantling buildings using a mechanized method, it is necessary to establish zones dangerous for people, and place machines (mechanisms) outside the zone of collapse of structures.

The driver's cabin must be protected from possible debris, and workers must be provided with safety glasses.

4.1.7 When dismantling buildings, as well as when removing waste and debris, it is necessary to take measures to reduce dust formation.

Those working in dusty conditions must be provided with respiratory protection against airborne dust and microorganisms (mold, fungi, their spores).

4.1.8 Before allowing workers into places with the possible appearance of gas or harmful substances, they must be ventilated. If gas appears unexpectedly, work should be stopped and workers should be removed from the danger zone.

Those working in places where gas may appear must be provided with protective equipment (gas masks).

4.2 Work procedure

4.2.1 Dismantling of buildings (dismantling of structures) must be carried out sequentially from top to bottom.

It is prohibited to dismantle buildings simultaneously in several tiers along the same vertical.

4.2.2 When dismantling buildings, it is necessary to leave passages to workplaces.

When dismantling the roof and external walls, workers must use a safety belt.

4.2.3 When dismantling cornices and hanging parts of the building, it is prohibited to stand on the wall. It is not allowed to carry out work during ice, fog and rain, excluding visibility within the work front, thunderstorms and wind at a speed of 15 m/s or more.

Regulatory documentation database: www.complexdoc.ru

4.2.4 When dismantling buildings, it is necessary to prevent spontaneous collapse or falling of structures.

Unstable structures located in the work area should be removed or secured, or strengthened in accordance with the PPR.

It is prohibited to cut chimneys, stone pillars and walls manually, or to collapse them onto the ceiling.

4.2.5 When dismantling buildings using the “felling” method, the length of the attached cables (ropes) should be 3 times the height of the building.

4.2.6 When dismantling buildings by explosive means, it is necessary to comply with the requirements PB 13-407.

4.2.7 When dismantling structures and equipment using cranes, it is necessary to comply with the requirements of Section 8 of these rules and regulations.

Methods of release, as well as slinging schemes for dismantled structures must comply with those provided for in the PPR.

4.2.8 Materials obtained from the dismantling of buildings, as well as construction waste, must be lowered through closed chutes or in closed boxes or containers using lifting cranes. The bottom end of the chute should be no higher than 1 m above the ground or enter the bunker.

Disposing of waste without chutes or other devices is permitted from a height of no more than 3 m. Dangerous areas in these places must be fenced off. The dimensions of the danger zone are established in accordance with SNiP 12-03.

4.2.9 Materials obtained during the dismantling of buildings must be stored in specially designated areas.

5. EARTHWORK

5.1 Organization of work

Regulatory documentation database: www.complexdoc.ru

5.1.1 When performing excavation and other work related to placing workplaces in excavations and trenches, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

- falling objects (pieces of rock);

- moving machines and their working parts, as well as objects moved by them;

- location of the workplace near a height difference of 1.3 m

and more;

- increased voltage in an electrical circuit, the closure of which can occur through the human body;

- chemically hazardous and harmful production factors.

5.1.2 In the presence of dangerous and harmful production factors specified in 5.1.1, the safety of excavation work must be ensured based on the implementation of the following labor protection decisions contained in the organizational and technological documentation (POS, PPR, etc.):

- determination of the safe steepness of loose slopes of pits, trenches (hereinafter- notches) taking into account the load from the machines

and soil;

- determination of the design of fastening the walls of pits and trenches;

- selection of types of machines used for soil development and places of their installation;

- additional measures to control and ensure slope stability due to seasonal changes;

- determination of installation locations and types of fencing for pits and trenches, as well as stairs for descending workers to the work site.

5.1.3 In order to prevent soil erosion, landslides, and collapse of excavation walls in production areas

Regulatory documentation database: www.complexdoc.ru

Before excavation work begins, it is necessary to ensure the drainage of surface and groundwater.

The work site must be cleared of boulders, trees, and construction debris.

5.1.4 Excavation work in the security zone of high-voltage cables, an existing gas pipeline, other communications, as well as in areas with possible pathogenic contamination of the soil (landfills, cattle burial grounds, cemetery, etc.) must be carried out according to a permit after obtaining permission from the organization operating these communications or the sanitary inspection authority.

Work under these conditions should be carried out under the direct supervision of the work manager, and in the security zone of live cables or existing gas pipelines, in addition, under the supervision of employees of organizations operating these communications.

5.1.5 Development of soil in the immediate vicinity of existing underground utilities is permitted only with the help of shovels, without the use of impact tools.

The use of earth-moving machines at the intersection of excavations with existing communications that are not protected from mechanical damage is permitted in agreement with the organizations that own the communications.

5.1.6 If communications, underground structures or explosive materials not specified in the project are discovered during excavation work, the excavation work must be suspended until permission from the relevant authorities is obtained.

5.2 Organization of workplaces

5.2.1 When placing workplaces in excavations, their dimensions, adopted in the project, must ensure the placement of structures, equipment, accessories, as well as passages at and to workplaces with a clear width of at least 0.6 m, and at workplaces-also the required space in the work area.

5.2.2 Excavations developed on streets, driveways, courtyards of populated areas, as well as in other places where possible

Regulatory documentation database: www.complexdoc.ru

the presence of people must be protected by protective fences taking into account the requirements of state standards. Warning signs must be installed on the fence, and warning lights must be installed at night.

5.2.3 For the passage of people through excavations, transition bridges must be constructed in accordance with the requirements of SNiP 12-03.

To access work places in excavations, ladders or flight ladders with a width of at least 0.6 m with guardrails or ladders (wooden - no more than 5 m long) should be installed.

5.2.4

V recesses with vertical walls without fastening in sandy, silty-clayey and thawed soils above the groundwater level and in the absence of underground structures near them, it is allowed at their depth of no more than, m:

- 1.0 - in non-compacted bulk and natural sandy soils;

1.25 - in sandy loams;

- 1.5 - in loams and clays.

5.2.5 When the average daily air temperature is below minus 2 °C, it is allowed to increase the maximum depth of the vertical walls of excavations in frozen soils, except for loose frozen soils, compared to the value established in 5.2.4 by the depth of soil freezing, but not more than 2 m.

5.2.6 Carrying out work related to finding workers

V excavations with slopes without fastenings in bulk, sandy and silty-clayey soils above the groundwater level (taking into account capillary rise) or soils drained by artificial dewatering, is allowed at the excavation depth and slope steepness indicated in Table 1.

Table 1

Regulatory documentation database: www.complexdoc.ru

Slope steepness (ratio of its height to foundation) at excavation depth, m, no more

Types of soils

Bulk |

|||||

unpacked |

|||||

Sandy |

|||||

Loam |

|||||

Loess |

Notes: 1. When layering different types of soil, the steepness of the slopes is assigned according to the least resistant type from slope collapse;

2. Uncompacted fill soils include soils with a filling age of up to two years for sandy soils; up to five years - for silty-clayey soils.

5.2.7 The steepness of the slopes of excavations with a depth of more than 5 m in all cases and a depth of less than 5 m under hydrological conditions and types of soil not provided for 5.2.12, as well as slopes exposed to moisture, must be established by the project.

5.2.8 The design of fastening the vertical walls of excavations up to 3 m deep in soils of natural moisture should, as a rule, be made according to standard designs. In case of greater depth, as well as complex hydrogeological conditions, the fastening must be carried out according to an individual project.

5.2.9 When installing fasteners, their upper part should protrude above the edge of the recess by at least 15 cm.

Regulatory documentation database: www.complexdoc.ru

5.2.10 Before allowing workers into excavations with a depth of more than 1.3

m the responsible person must check the condition of the slopes, as well as the reliability of fastening the walls of the excavation.

Boulders and stones, as well as loose soil found on slopes, must be removed.

5.2.11 The admission of workers into excavations with slopes that have been wetted is permitted only after a thorough inspection by the person responsible for ensuring the safety of the work, the condition of the soil of the slopes and the collapse of unstable soil in places where “peaks” or cracks (delaminations) are found.

5.2.12 Excavations developed in winter must be inspected upon the onset of a thaw, and based on the inspection results, measures must be taken to ensure the stability of the slopes

and fastenings.

5.2.13 The development by rotary and trench excavators in cohesive soils (loams and clays) of excavations with vertical walls without fastening is allowed to a depth of no more than 3 m. In places where workers are required, fastenings must be installed or slopes developed.

When extracting soil from excavations using buckets, it is necessary to install protective canopies to protect those working in the excavation.

5.3 Work procedure

5.3.1 It is necessary to install fasteners in the direction from top to bottom as the excavation is developed to a depth of no more than 0.5 m.

5.3.2 It is not allowed to dig up soil in excavations.

The soil removed from the excavation must be placed at a distance of at least 0.5 m from the edge of this excavation.

5.3.3 When developing excavations in the ground with a single-bucket excavator, the height of the face must be determined by the PPR in such a way that “peaks” of the soil do not form during the work.

Regulatory documentation database: www.complexdoc.ru

5.3.4 When the excavator is operating, it is not allowed to carry out other work from the face and workers are not allowed to be within the radius of the excavator plus 5 m.

5.3.5 Dismantling of fasteners in recesses should be carried out from the bottom up as the recess is backfilled, unless otherwise provided by the PPR.

5.3.6 During mechanical impact loosening of the soil, workers are not allowed to be located at a distance closer than 5 m from the loosening sites.

5.3.7 One-sided backfilling of sinuses during the construction of retaining walls and foundations is allowed in accordance with the PPR after measures have been taken to ensure the stability of the structure, under the accepted conditions, methods and order of backfilling.

5.3.8 When developing, transporting, unloading, leveling and compacting soil with two or more self-propelled or trailed machines (scrapers, graders, rollers, bulldozers), going one after another, the distance between them must be at least 10 m.

5.3.9 Dump trucks when unloading on embankments, as well as when filling excavations, it should be installed no closer than 1 m from the edge of the natural slope; Unloading from overpasses that do not have protective (fender) bars is prohibited.

The unloading locations for vehicles must be determined by the traffic controller.

5.3.10 It is prohibited to develop soil with bulldozers and scrapers when moving uphill or downhill, with an inclination angle greater than that specified in the machine's passport.

5.3.11 The presence of workers and other persons in areas where soil compaction work is being carried out with free-falling compactors is not allowed, closer than 20 m from the base machine.

5.4 Special methods of work production

5.4.1 When developing quarries, it is necessary to comply with the requirements of regulatory documents of the State Mining and Technical Supervision of Russia.

Regulatory documentation database: www.complexdoc.ru

5.4.2 When developing rocky, frozen earthen soils using explosive methods, it is necessary to comply with the requirements PB 13-407.

5.4.3 If it is necessary to use machines in difficult conditions (cutting soil on a slope, clearing rubble), you should use machines equipped with protective equipment that prevent workers from being exposed to hazardous production factors that arise in these conditions (falling objects and overturning).

5.4.4 In case of electrical heating of the soil, the voltage of the power source should not be higher than 380 V.

The heated area of soil must be fenced off, safety signs installed on the fence, and illuminated at night. The distance between the fence and the contour of the heated area must be at least 3 m. Workers and other persons are not allowed to stay in the heated area.

5.4.5 Temporary power supply lines to heated areas of the ground must be carried out with insulated wire,

A After each movement of electrical equipment and re-wiring, the insulation resistance should be measured with a megohmmeter.

5.4.6 When developing soil using hydromechanization, the requirements of state standards must be met.

6. CONSTRUCTION OF ARTIFICIAL FOUNDATIONS AND DRILLING OPERATIONS

6.1 Organization of work

6.1.1 When constructing artificial foundations and performing drilling operations, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

- collapsing rocks (soils);

- moving machines and their working parts, as well as structures and objects they move;

Regulatory documentation database: www.complexdoc.ru

- overturning of cars, falling of piles and their parts;

6.1.2 In the presence of dangerous and harmful production factors specified in 6.1.1. The safety of the installation of artificial foundations and drilling operations must be ensured on the basis of the implementation of the following labor protection decisions contained in the organizational and technological documentation (POS, PPR, etc.):

- determination of methods and selection of mechanization means for carrying out work;

- establishing the sequence of work;

- development of a scheme for installation and dismantling of equipment, as well as its movement on the site;

- determination of the range and required quantity of collective protective equipment necessary for use in the design of machines, as well as in the organization of workplaces.

6.1.3 Drilling operations and work on constructing artificial foundations should be carried out in compliance with the requirements of section 5 real rules and regulations.

6.1.4 Pile driving and drilling machines must be equipped with limiters for the lifting height of the drilling tool or load-handling device and an audible alarm.

6.1.5 Ropes must have a certificate manufacturer or their testing certificate; lifting equipment must be tested and have tags or stamps confirming their load-carrying capacity and the date of testing.

6.1.6 The maximum weight of the hammer and pile for a pile driver, according to the machine’s passport, must be indicated on its truss or frame.

6.1.7 Distance between installed piling or drilling machines and buildings located near them

Regulatory documentation database: www.complexdoc.ru

determined by the PPR. When operating these machines, a danger zone should be established at a distance of at least 15 m from the wellhead or the place where the pile is driven.

6.1.8 The movement of piling and drilling machines should be carried out along a pre-planned horizontal path when the machine structure is in the transport position.

6.1.9 When driving piles with a floating pile driver, it is necessary to ensure its reliable mooring to anchors fixed on the shore or at the bottom, as well as communication with the shore using duty vessels or a pedestrian bridge.

The floating pile driver must be provided with lifebuoys

And by boat. It is not allowed to carry out piling work on rivers and reservoirs with waves of more than 2 points.

6.1.10 Driving piles from ice is permitted only if there are special measures in the PPR to ensure the strength of the ice cover.

6.1.11 When work is stopped, drilled wells must be covered with shields or fenced. Safety warning signs must be installed on boards and fences

And signal lighting.

6.1.12 Vibratory hammers must be equipped with suspended inventory platforms to accommodate workers who are attaching the head of the vibrating hammer to the shell.

The width of the platform deck must be at least 0.8 m. The platform deck must be fenced in accordance with the requirements of SNiP 12-03.

6.1.13 The inside walls of the sink well must be equipped with at least two securely fastened hanging ladders.

6.1.14 It is necessary to install protective canopies along the inner perimeter of the sinkhole. The dimensions, strength and installation procedure of the canopies must be determined in the PPR.

6.1.15 The rooms where solutions for chemically fixing soil are prepared must be equipped

Regulatory documentation database: www.complexdoc.ru

ventilation and appropriate containers for storing materials.

6.2 Work procedure

6.2.1 Installation, dismantling and movement of piling and drilling machines should be carried out under the direct supervision of persons responsible for the safe performance of these works.

Installation, dismantling and movement of piling and drilling machines during winds of 15 m/s or more or thunderstorms are not allowed.

6.2.2 The technical condition of piling and drilling machines (reliability of fastening units, serviceability of connections and working decks) must be checked before the start of each shift.

6.2.3 Before lifting piling or drilling machine structures, their elements must be securely secured, and tools and loose objects must be removed.

When lifting a structure assembled in a horizontal position, all other work must be stopped within a radius equal to the length of the structure plus 5 m.

6.2.4 During the period of operation of piling or drilling machines, persons not directly involved in the performance of these works are not allowed to approach the machines at a distance of less than 15 m.

6.2.5 Before starting drilling or piling work, you must check:

- serviceability of sound and light signaling devices, lifting height limiter of the lifting body;

- the condition of the ropes for lifting mechanisms, as well as the condition of lifting devices;

- serviceability of all mechanisms and metal structures.

6.2.6 Before inspecting, lubricating, cleaning or troubleshooting a drilling machine or pile driver, the drilling tool or pile driving mechanism must be lowered and placed in a stable position, and the engine stopped and turned off.

Regulatory documentation database: www.complexdoc.ru

6.2.7 The lowering and raising of the drilling tool or pile is carried out after giving a warning signal.

While lifting or lowering a drilling tool, it is prohibited to perform work on the copter or drilling machine that is not related to the specified processes.

6.2.8 Lifting the pile (sheet pile) and the pile hammer must be carried out using separate hooks. If there is only one hook on the pile driver for installing the pile, the pile hammer must be removed from the hook and installed on a reliable locking bolt.

When lifting, the pile must be kept from swinging and torsion using braces.

Simultaneous lifting of the piling hammer and the pile is not allowed.

6.2.9 Piles are allowed to be pulled in a straight line within the visibility of the driver's driver only through a tapping block fixed at the base of the pile driver. It is prohibited to pull piles with a pile driver to a distance of more than 10 m and with their deviation from the longitudinal axis.

6.2.10 When cutting piles driven into the ground, it is necessary to take measures to prevent the part being removed from suddenly falling.

6.2.11 Installation of piles and piling equipment is carried out without interruption until they are completely secured.

Leaving them hanging is not allowed.

6.2.12 When driving piles using vibratory drivers, it is necessary to ensure a tight and reliable connection of the vibratory driver with the pile cap, as well as the free condition of the ropes supporting the vibratory driver.

6.2.13 The vibrator should be turned on only after it has been secured to the pile and the supporting pulleys have been loosened. The weakened state of the pulleys must be maintained throughout the entire operating time of the vibrator.

The vibrator should be turned off during every break in work.

Regulatory documentation database: www.complexdoc.ru

6.2.14 When immersing shell piles, workers’ access to the suspended platform for attaching the head of a vibratory driver or the next section of the shell pile to the immersed pile shell is permitted only after the supplied structure has been lowered by a crane to a distance of no more than 30 cm from the top of the immersed shell pile.

6.2.15 The sequence of soil development under the knife edge of the drop well should ensure its stability. The depth of soil development from the edge of the well knife is determined according to the PPR.

It is not allowed to develop soil below 1 m from the edge of the well knife.

6.2.16 When developing mobile soils with drainage or when there is a layer of such soils above the well blade, measures must be taken to ensure rapid evacuation of people in the event of a sudden breakthrough of the soil and flooding of the well.

6.2.17 Equipment and pipelines intended to perform soil freezing work must be tested:

- freezing station apparatus after completion of installation

- pneumatic or hydraulic pressure specified in the passport, but not less than 1.2 MPa for the suction side and 1.8 MPa for the discharge side;

- freezing columns before lowering into wells - with hydraulic pressure of at least 2.5 MPa.

6.2.18 Construction work in the area of artificial soil consolidation by freezing is allowed only after the ice-soil fencing reaches its designed thickness. Permission to carry out work must be formalized in an act.

6.2.19 Extracting soil from a pit that has an ice-soil fence is permitted if the frozen wall is protected from rain and sunlight. When working, measures should be taken to protect the ice-ground fencing from mechanical damage.

Regulatory documentation database: www.complexdoc.ru

6.2.20 The procedure for monitoring the size and temperature of the ice-soil fencing of the pit during the freezing process

And ground thawing must be determined by the project.

6.2.21 Pipelines, hoses and injectors used for injection work on chemical consolidation of soils (silicatization, etc.) must be subjected to hydraulic testing with a pressure equal to one and a half times the working pressure, but not lower than 0.5 MPa.

6.2.22 Autoclave-type silicate cookers and other devices that are under pressure during operation must be subjected to regular technical inspections and periodic hydraulic tests in accordance with the requirements of the State Mining and Technical Supervision Authority of Russia.

7. CONCRETE WORK

7.1 Organization of work

7.1.1 When preparing, supplying, laying and maintaining concrete, procuring and installing reinforcement, as well as installing and dismantling formwork (hereinafter referred to as concrete work), it is necessary to take measures to prevent workers from being exposed to hazardous and harmful production factors associated with the nature of the work:

- location of workplaces near a height difference of 1.3 m or more;

- moving cars and objects they move;

- collapse of structural elements;

Noise and vibration;

- increased voltage in an electrical circuit, the closure of which can occur through the human body.

7.1.2 In the presence of dangerous and harmful production factors specified in 7.1.1, the safety of concrete work must be ensured based on the implementation of the following labor protection decisions contained in the organizational and technological documentation (POS, PPR, etc.):

Regulatory documentation database: www.complexdoc.ru

- determination of mechanization means for preparing, transporting, supplying and laying concrete;

- determining the load-bearing capacity and developing a formwork design, as well as the sequence of its installation and disassembly order;

- development of measures and means to ensure workplace safety at heights;

- development of measures and means for the care of concrete in the cold and warm seasons.

7.1.3 When installing formwork, as well as installing reinforcement cages, you should be guided by the requirements of Section 8 “Installation work” of these rules and regulations.

7.1.4 Cement must be stored in silos, bunkers, chests

And other closed containers, taking precautions against spraying during loading and unloading. The loading openings must be closed with protective grilles, and the hatches in the protective grilles must be locked.

7.1.5 When using steam to heat inert materials located in bunkers or other containers, measures should be taken to prevent steam from penetrating into work areas.

The descent of workers into chambers heated by steam is allowed after the steam supply is turned off, as well as after the chamber and the materials and products contained in it have cooled to 40 °C.

7.2 Organization of workplaces

7.2.1 The placement of equipment and materials on the formwork that are not provided for by the PPR, as well as the presence of people not directly involved in the work on the installed formwork structures, are not allowed.

7.2.2 To transfer workers from one workplace to another, it is necessary to use stairs, transition bridges and gangways that meet the requirements SNiP 12-03.

Regulatory documentation database: www.complexdoc.ru

7.2.3 When installing prefabricated formwork for walls, crossbars and vaults, it is necessary to provide for the installation of working floors with a width of at least 0.8 m with fences.

7.2.4 The floor formwork must be fenced around the entire perimeter. All openings in the working floor of the formwork must be closed. If it is necessary to leave these holes open, they should be tightened with wire mesh.

7.2.5 After cutting off part of the sliding formwork and suspended scaffolding, the end sides must be fenced.

7.2.6 To protect workers from falling objects on suspended scaffolds, canopies should be installed along the outer perimeter of sliding and adjustable formwork with a width no less than the width of the scaffolding.

7.2.7 Walking on laid reinforcement is allowed only on special floorings with a width of at least 0.6 m laid on the reinforcement frame.

7.2.8 Removable lifting devices, slings and containers intended for supplying concrete mixture by lifting cranes must be manufactured and inspected in accordance with PB 10-382.

7.2.9 In areas where reinforcement is tensioned, in places where people pass, protective barriers with a height of at least 1.8 m must be installed.

Devices for tensioning reinforcement must be equipped with an alarm that is activated when the tensioner drive is turned on.

It is prohibited for people to stay within a distance of 1 m from reinforcing bars heated by electric current.

7.2.10 When using concrete mixtures with chemical additives, protective gloves and goggles should be used.

7.2.11 Workers laying concrete on a surface with a slope of more than 20° must use safety belts.

Regulatory documentation database: www.complexdoc.ru

7.2.12 The overpass for supplying concrete mixture by dump trucks must be equipped with fenders. Passages with a width of at least 0.6 m must be provided between fender bars and fences. Transverse fender bars must be installed on dead-end overpasses.

When cleaning the bodies of dump trucks from the remains of the concrete mixture, workers are prohibited from being in the body of the vehicle.

7.2.13 Preparation and enlarged assembly of reinforcement must be carried out in places specially designed for this.

7.2.14 The area where concrete is electrically heated must have a protective fence that meets the requirements of state standards, a light alarm and safety signs.

7.3 Work procedure

7.3.1 The operation of mixing machines must comply with the following requirements:

- cleaning pits for loading buckets should be carried out after the bucket is securely secured in the raised position;

- Cleaning the drums and troughs of mixing machines is allowed only after stopping the machine and relieving the voltage.

7.3.2 When performing work on the preparation of reinforcement, it is necessary to:

- install protective fences for workplaces intended for unwinding coils (coils) and straightening reinforcement;

- when cutting reinforcement bars with machines into sections less than 0.3 m long, use devices that prevent them from scattering;

- install protective fences for workplaces when processing reinforcement bars protruding beyond the dimensions of the workbench, and for double-sided workbenches, in addition, divide the workbench in the middle with a longitudinal metal safety mesh with a height of at least 1 m;

Regulatory documentation database: www.complexdoc.ru

- stack the prepared reinforcement in specially designated places;

- cover the end parts of the reinforcement bars with shields in places of common passages having a width of less than 1 m.

7.3.3 Elements of reinforcement frames must be packaged taking into account the conditions for their lifting, storage and transportation to the installation site.

7.3.4 Bunkers (tubs) for concrete mixture must meet the requirements of state standards. Moving a loaded or empty hopper is only permitted when the gate is closed.

7.3.5 When laying concrete from a bunker, the distance between the bottom edge of the bunker and the previously laid concrete or the surface on which the concrete is laid should be no more than 1 m, unless other distances are provided for by the PPR.

7.3.6 Every day, before starting to lay concrete in the formwork, it is necessary to check the condition of the container, formwork and scaffolding. Detected malfunctions should be corrected immediately.

Before starting to lay the concrete mixture with a vibrating robot, it is necessary to check the serviceability and reliability of fastening all its links to each other and to the safety rope.

7.3.7 When supplying concrete using a concrete pump, you must:

- carry out work on installation, dismantling and repair of concrete pipelines, as well as removing plugs from them only after the pressure has been reduced to atmospheric;

- remove all workers from the concrete pipeline at a distance of at least 10 m during purging;

- lay concrete pipes on spacers to reduce the impact of dynamic load on the reinforcement frame and formwork when supplying concrete.

7.3.8 Removing a plug in a concrete pipeline with compressed air is permitted provided:

Regulatory documentation database: www.complexdoc.ru

- the presence of a protective shield at the outlet of the concrete pipeline;

- workers are located at a distance of at least 10 m from the outlet of the concrete pipeline;

- supplying air into the concrete pipeline evenly, without exceeding the permissible pressure.

If the plug cannot be removed, the pressure should be relieved.

V concrete pipe, tap to find the location of the plug

V concrete pipe, uncouple the concrete pipe and remove the plug or replace the clogged link.

7.3.9 When installing formwork elements in several tiers, each subsequent tier should be installed after securing the lower tier.

7.3.10 Dismantling of the formwork should be done after the concrete reaches the specified strength.

The minimum strength of concrete during stripping of loaded structures, including from its own load, is determined by the PPR and agreed with the design organization.

7.3.11 When dismantling the formwork, it is necessary to take measures against accidental falling of formwork elements, collapse of supporting scaffolding and structures.

7.3.12 When moving sections of rolling formwork and mobile scaffolding, measures must be taken to ensure the safety of workers. Persons not participating in this operation are prohibited from being on sections of formwork or scaffolding.

7.3.13 When compacting a concrete mixture with electric vibrators, moving the vibrator by live cables is not allowed, and during breaks in work and when moving from one place. Otherwise, electric vibrators must be turned off.

7.3.14 When constructing technological holes for passing pipelines in concrete and reinforced concrete structures using diamond annular drills, it is necessary to fence off the danger zone at the site where the core is expected to fall.

7.3.15 When electrically heating concrete, installation and connection of electrical equipment to the power supply network should only be carried out

Regulatory documentation database: www.complexdoc.ru

electricians with a qualification group for electrical safety of at least III.

7.3.16 In the electrical heating zone, it is necessary to use insulated flexible cables or wires in a protective hose. It is not allowed to lay wires directly on the ground or over a layer of sawdust, as well as wires with damaged insulation.

7.3.17 The area where concrete is electrically heated must be under 24-hour supervision by electricians who are installing the electrical network.

The presence of workers and the performance of work in these areas is not allowed, with the exception of work performed under the permit in accordance with inter-industry rules on labor protection during the operation of electrical installations.

7.3.18 Open (non-concrete) reinforcement of reinforced concrete structures connected to the area under electrical heating is subject to grounding (zeroing).

7.3.19 After each movement of electrical equipment used when heating concrete to a new location, the insulation resistance should be measured with a megohmmeter.

APPENDIX A

List of regulatory legal acts referred to in these rules and regulations

1. SNiP 12-03-2001 "Occupational safety in construction. Part