An important role in the construction of a reliable and durable building is the design stage. If we talk about the roof, it is important to choose the right roof slope from corrugated board. It's not just a matter of personal preference and aesthetics. The size of the attic or attic, the presence or absence of problems with snow accumulation and resistance to wind loads depend on the angle of the roof. In order to determine the slope of the roof, it is important to consider many factors.

Some believe that the angle of inclination is associated only with the desire of the customer and the architectural idea. In fact, there are two groups of factors on which the minimum slope depends:

- Climatic conditions.

- Features of roofing material.

climate factor

There are several climate features that can significantly affect the angle of inclination:

Unlike rain, snow very often lingers on the roof surface. If a meter or more of snow can fall in the area, then it is difficult to imagine how powerful the roof must be to withstand such a mass if it does not roll down. The greater the angle of inclination, the more likely it is that under its own weight the snow mass will slide down. It is unlikely that anyone will want to clean not only the yard, but also the roof from snow in winter. Therefore, in such regions there may be structures with a roof slope of 40 ° or more.

The dependence of the angle of inclination on the roofing material

Obviously, for areas with heavy rain and snow, you need to make a roof at a large angle, and in areas with strong winds - with a minimum angle.

The choice of the minimum slope is also influenced by the characteristics of the roofing material. Each of them creates its own bottom bar for the corner of the roof. Climatic factors can increase this value, however, it is not worth making the roof more gentle than the material suggests.

- Ondulin. The minimum ramp slope is 6°.

- Soft tiles. Minimum 11° tilt.

- Decking. Not less than 12 °, otherwise it will be necessary to deal with gluing the joints of the profiled sheet.

- Metal tile. The minimum slope value is 14°.

- Roll materials in two layers - 15°. If a three-layer coating is used, it is possible to make the roof completely flat (2-5 °).

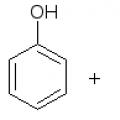

Various roofing materials

SNiP requirements

Slate, tiles and other piece materials. The minimum slope value is 22°.

According to the requirements of SNiP, for a roof made of corrugated board, the minimum allowable threshold is 8 °, however, it is only valid for outbuildings and industrial structures. The roof angle of corrugated board for residential buildings is at least 10 °. but construction firms guarantee only for structures with a slope of 12° or more. The maximum tilt angle can even be 70° or more.

However, it is worth remembering that the smaller the height of the roof and, accordingly, the angle of the slope, the smaller the distance you need to make between the boards of the crate. As you can see from the table below, a roof with a slight slope requires a continuous batten.

SNiP requirements

Advantages and disadvantages of the minimum angle of inclination

Why is there even a question about the minimum allowable rate for gable and pitched roof? What are the advantages of low structures? The following are some of their advantages:

- Reducing the consumption of roofing material. If the roof is high, it needs a more massive truss system. By reducing the slope angle, you can reduce the cost of the entire structure. However, it is worth considering that the overlap of sheets will be greater for low roofs.

- Roofing safety.

- Shed roofs are devoid of a ridge, and hence the entire scope of work with it.

In addition to the advantages, a low roof has a number of disadvantages:

- Slow water flow, which means a high probability of leaks and damage to the roofing pie. To do this, the sheets in the places of overlap must be sealed.

- High snow load on the roof. In some cases, with heavy snowfalls, it will be necessary to independently clean the roof from the profiled sheet from snow.

- Inability to equip a residential attic.

Calculation of the angle of inclination

Taking into account all of the above factors, you should decide which angle of inclination will be optimal for a particular situation. First of all, if you are going to build a house, you need to look at the angle of inclination of the roof of the neighbors, because the climatic features in the same area are the same.

It is also important to determine how the attic space will be used. If you need to create one or more living rooms, then the roof height will be greater than the minimum allowable.

There are several types of roofs from a professional sheet:

- Low-slope (14° and less). The vertical overlap of the material is 20 cm, and the joint is made in three waves.

- Medium slope (15-30°). The vertical overlap is 15-20 cm and the overlap is 1 or 2 waves.

- Steep (30° and above). The minimum overlap is 10-15 cm, and the overlap is in one wave.

As you can see, the slope of the roof also affects the consumption of roofing material. If you take into account all building codes and rules, as well as correctly determine the snow and wind loads, you can create the optimal angle of inclination of the roof for the building under construction.

One of the main parameters in the characterization of the roof is the angle of inclination of its slopes relative to the horizontal plane, or slope. The value of this indicator depends on a number of important operational and design features roofs. Therefore, the slope is not chosen arbitrarily, but depending on the climatic conditions of the area, the wind rose, the amount of precipitation, the design of the truss system, roofing and the length of the slopes. We will consider such roofing material, as profiled steel sheet or corrugated board, and the minimum roof slope of corrugated board recommended by building codes.

The slope is usually measured in percent or degrees, while the ratio between them is determined from the tables, 1 ° = 1.7%, but 45 ° = 100%.

With the maximum slope of the roof, the snow load is reduced to a minimum and rainwater is drained easily and quickly, but at the same time, the windage of the roof increases many times over. With minimal slopes, windage can be neglected, but the requirements for tightness and watertightness of the roof increase, the load also increases, created by pressure snow. Therefore, for different materials roofing recommend optimal and minimum slope values.

Table of ratios of degrees and percentages of slope

For a builder who independently determines the angle of inclination of the slopes of his roof, it is enough to recall the basics of trigonometry. So, the height of the ridge will be equal to the opposite leg, half the width of the ceiling (the width of the house) or the lower puff will be equal to the adjacent leg, the length of the slope will be the hypotenuse. We should determine the angle between the hypotenuse (slope) and the adjacent leg (overlap).

Divide the height of the skate by the length rafter leg or slope, we get the sine of the angle of inclination. Further on the table or using a calculator, you can easily determine its value in degrees or percentages. You can also use cosine or tangent to define an angle. These are the ratios of half the width of the overlap to the length of the slope or the height of the ridge to half the width of the overlap, respectively.

L - hypotenuse, H - height of the ridge, B / 2 - half the width of the overlap

There is another way to determine the slope of the roof, which is based on the fact that the height of the ridge (speaking of the height of the ridge, here and earlier it meant the distance from the ceiling to the upper point of intersection of the rafters) is divided by half the width of the ceiling and multiplied by 100. Next, the slope is determined according to the table.

Thus, when designing a truss system, we have two given values: the width of the house and the desired angle of inclination. Next, using simple trigonometric functions, we calculate the distance from the ceiling to the ridge and the length of the rafters.

Characteristics of profiled sheet

Profiled sheet, or corrugated board is construction material, which is a cold-rolled steel sheet, stamped in the form of a corrugated or trapezoidal profile. Next, the steel is coated with a layer of zinc or aluminum for anti-corrosion properties. At the final stage of production, the product is cut, and the sheets are painted by spraying a polymer powder dye using an electrostatic field, followed by heat treatment. The result is a galvanized steel profiled sheet with a protective polymer coating, which can have different colors.

The profiled sheet is used as an enclosing or bearing material in the construction of walls and roofs, as well as fences and other structures. The wall sheet is indicated by the letter "C", the roofing sheet is "H", the universal one is "NS". The length of the sheet can vary from 0.1 to 12 meters, the width - from 1.035 m to 1.8 m. The useful width differs from the overall width by 4 - 5 cm due to the overlap of the sheets during installation. The thickness of steel is different and ranges from 0.4 to 1 mm.

The most common corrugation shape is a trapezoid

The height of the corrugations (waves or profile trapezoid) for roofing profiled sheets is 20 or more millimeters. For small spans or with a continuous crate, it is also possible to use smaller corrugations with a height of 8 mm or more.

The minimum slope of a profiled sheet roof implies frequent or continuous lathing; with an increase in the slope, the lathing step also increases. The maximum step for corrugated roofs is up to 4 meters.

The crate for the profiled sheet is used differently, more often not solid

Roof slope from profiled sheet according to SNiP

Building codes recommend making a roof slope of corrugated board equal to 20 ° or 36.4%. At the same time, the minimum slope for industrial and economic facilities with a bearing profile must be at least 8 ° or 14.1%. For residential facilities and facilities intended for permanent human use, the minimum slope is assumed to be 10° or 17.6%.

At the same time, it should be taken into account that with a decrease in the angle of inclination of the slopes, the transverse and longitudinal overlap of the sheets increases, i.e. their effective area decreases. With a slope of more than 35 °, the overlap is at least 150 mm, if the slope is from 15 to 30 degrees - at least 200 mm, if the slope does not exceed 15 ° - the overlap is at least two waves long, while the joints should be treated with silicone or thiokol sealant. It is necessary to process both transverse and longitudinal joints.

It is better to entrust the installation of corrugated board to professionals

Decking is a good building material in terms of price / quality ratio, in addition, it looks good and has a wide color palette of coatings in its assortment. However, a very important role is played by the quality of its installation and the skill of the roofer, the selection of materials for the roofing cake, insulation and waterproofing. Therefore, trusting roofing work with profiled sheets, as well as the choice of the roof itself, is necessary only for competent specialists and experienced professionals with good recommendations.

Calculating the slope angle for a corrugated roof is the most important thing in terms of its durability. The wrong slope angle and after the first strong gust of wind your house may simply lose its roof!

If you want to avoid such a fate, then you have come to the right place. In this article, we will help determine the minimum slope of a corrugated roof. If it seems to you that an architect is guided only by aesthetic considerations when planning the roof of a house, then you are mistaken. The roofing system is very complex, because it takes into account a lot of nuances and a successful solution is achieved by careful selection of data and calculations.

In this article

What affects the slope of the roof from the profiled sheet?

When building a house, one of the main points to consider is the climate of the environment. These are moisture and windiness and the volume and frequency of precipitation. To determine the desired slope of the roof, you need to take into account three climatic factors:

- Snowfall level;

- Frequency and intensity of rains;

- Wind speed and direction.

I see little point in separately describing the impact of these factors on the roof. It is much more productive to explain how this effect depends on the angle of the roof slope. For example, snow, as the heaviest sediment, puts a lot of pressure on the roofing material. Therefore, it is undesirable to stay there for a long time. In this case, a reasonable solution would be to erect a steep roof, from which the snow of the critical layer will slide under its own weight.

The second determining factor is the type of material. The slope of the shed roof made of corrugated board will depend on how you install the profiled sheet. For example, wall and universal profiles are poorly suited for sloping roofs, for such profiled sheets with a large wave height are much better suited and vice versa.

When choosing a corner, also do not forget that from roofs at a small angle, water will not drain so quickly and in heavy rain, leaks at the junctions will be possible. The angle of inclination should be at least 12 degrees, then you can not worry about this problem. If the angle is smaller, then the joints must be additionally sealed.

Last but not least, the factor is the amount consumable and complexity roof structure. The smaller the angle, the more load goes to truss system and more material is wasted due to sheet overlap. This point requires more detailed consideration.

The dependence of the amount of overlap of sheets on the angle of inclination

The minimum slope of the roof from the profiled sheet is 12 degrees. With it, there is no need for additional sealing and you should not worry about leaks. But at the same time, in the interval between 12 and 14 degrees, there remains one more binding necessity. This is an increased overlap of sheets. For corrugated board and its economical use, the optimal slope is 15-30 degrees.

This table clearly demonstrates the dependence of the overlap size on the angle.

Yes, the material consumption is higher, but this is a quantitative indicator, but what about quality? With quality, the situation is identical: due to the fact that with a small slope of the corrugated roof, the material must be of the highest quality, because the sheet has a large load. And the sharper the angle, the less the load on each individual sheet, and the cheaper the profiled sheet is allowed.

The rafter system, with an increase in the angle, grows upward due to the rafters themselves, however, the load on them is diluted with additional structures. With a minimum roof slope, the rafters can be shorter, but technically complex additional struts become indispensable.

As you can see, set flat or close to flat roof from corrugated board can be completely unreasonable.

How to calculate the slope of the roof?

The calculation must necessarily include the following components:

- The weight of the battens, counter battens, insulation and other layers of the roof;

- Roofing weight;

- The level of snowfall in the region;

- Wind speed and direction in the region.

To give you an idea of the calculation process, let's take profiled sheet C21-1000-0.6 as an example. The mass of a square meter of this model is 5.4 kilograms. The next step is the miscalculation of the heat-insulating material. In our example, these will be basalt slabs 100 mm thick and with a density of 150 kg per cubic meter. The mass of a square meter will be 15 kg. The crate of pine timber will tighten approximately 28.3 kg per square meter and other components weigh 3 kilograms per square meter.

We add up all these components and get 5.4 + 15 + 28.3 + 3 = 51.7 kg / m².

Advice! To leave yourself room for maneuver, the resulting coefficient must be multiplied by 1.1. With this calculation, you will be able to freely change some of the materials of the roofing cake.

We will do the same, and as a result we will get a roof mass of 56.87 kg per square meter.

The next stage is the measurement of wind speed and snowfall in the region. On the Internet, it is not difficult to find a map of the snow load on the surface of the Russian Federation. Similarly, a wind load map is also available.

Our hypothetical house will be in the third snow region with a snow load of 180 kg per square meter. This figure refers to planes, for inclined surfaces there is a special coefficient µ. For angles less than 25 degrees, it is equal to 1, for angles from 25 to 60 there is a formula µ: (60-a) * (60-25), in which "a" is the desired roof slope. For roofs with an angle greater than 60 degrees, the snow load is not taken into account.

Wind load is calculated using the formula W=Wn*Kh*C. In it, Wn is the average wind load in the region, Kh is the building height coefficient and C is the aerodynamic coefficient from -1.8 to 0.8, depending on the slope of the roof. Our load is 23, C is 0.8, and Kh is found from the following table:

Total 23*1*0.8-18.4 kg/m2.

We add up the mass of the roof and the wind load and get 56.87 + 18.4 = 75.27 kg / m2. The second most important figure is the maximum allowable weight for our sheet. With a support step of 1.8 m, it is 253 kg per square meter.

If the slope is less than 25 degrees, the mass of the snow load will be equal to the average for the region, that is, 180 kg. Then 180_75.27-255.27 kg/m2 0 the mass of the roof with all possible loads is greater than the maximum bearing capacity for the sheet. Then the desired angle is between 25 and 60 degrees.

This adds the coefficient µ to our formula and the level of the slope of the roof from the profiled sheet lends itself to such a calculation:

180*(60-a)*(60-25)+75.27=253

The result of this equation is the angle a we need. It is 25.441 degrees, it can be rounded up to 26 - this will be the minimum slope of the corrugated roof. By the same calculation, by the way, you can calculate the angle of inclination of a shed roof.

Use the formulas indicated in the article and build correctly!

Decking is a practical, inexpensive and durable material used to cover the roofs of low-rise private houses, garden or outbuildings, and industrial facilities. Roofs made of this material are famous for their reliability and resistance to corrosion. With proper calculation and installation, such a design can last up to 20-25 years. The key to a long service life of corrugated board is considered to be the right angle of inclination of the roof, on which the efficiency of water drainage and snow removal from the surface of the slope depends. In this article, we will talk about the recommended and minimum slope of the profiled sheet roofing, which provides reliable waterproofing of the structure.

To choose the right angle of inclination of the roof from corrugated board, you need to know the technical and operational properties this material. It is made of rolled rolled steel with a thickness of 0.5-0.7 mm, which is coated with a zinc alloy and a polymer or paint coating during the production process. With the help of powerful rollers, a trapezoidal or rectangular profile is extruded on the surface of the steel sheet. The profiling process increases the strength and load-bearing capacity of this roofing material. There are 3 categories of profiled sheet:

- Wall. This category of corrugated board is made of the thinnest steel and has a small profile height. A wall profiled sheet costs less, and is used for wall cladding, making fences and fences, and building roofs with a small area.

- Carrier. The bearing profiled sheet is supplied with additional stiffening ribs, which increase the bearing capacity of the material. It is made from a thicker steel billet, has a profile height of up to 114 mm. It is used for the construction of garages, hangars, floors and roofs with a large area and the distance between the rafters.

- Universal. Universal profiled sheet has medium characteristics, allowing this material to be used for most construction tasks. This type of coating is marked with the letters "NS"

Note! According to building codes, for arranging ceilings, it is allowed to use wall, load-bearing and universal profiled sheets as a roofing material if the height of the material profile exceeds 20 mm and the roof slope is at least 8 degrees.

Slope Selection Factors

It often seems to non-professional builders who are unfamiliar with building codes that the slope of the roof from the profiled sheet is selected only in accordance with architectural style facilities and taste of the customer. However, this approach is a gross mistake, because the choice of this important indicator is influenced by factors that can be conditionally divided into 2 groups: technical and mechanical. The technical factors that are taken into account when determining the angle of inclination of a corrugated roof are the properties of the material itself. Climate factors include:

- When determining the angle of inclination of the roof from the profiled sheet, first of all, the snow load is taken into account. In regions where a large amount of snow falls, structures are made with a slope of 20-25 degrees to prevent the formation of a snow cap on the surface of the slopes.

- An important factor that is taken into account in the process of designing a roof structure is the amount of rainfall. The more precipitation falls in the construction region, the steeper the angle of inclination of the roof is made.

- Also, the slope of the slopes from the profiled sheet is influenced by the wind load. If strong, gusty winds blow in the construction region, then the roof is made more gentle to reduce the windage of the structure.

Important! When determining the roof slope, the most important factors are the recommendations of the manufacturer of the roofing material and the climatic conditions in the construction area. After that, a design project is created, reflecting the composition, cross-section and relative position of the elements of the truss system.

Minimum slope

According to building codes, the minimum permitted roof slope from a profiled sheet is 8 degrees, provided that a continuous or frequent batten is installed. However, experienced roofers claim that, subject to some special conditions, this material can also be laid on more gentle slopes. If the angle of inclination of the roof is less than the recommended one, the overlap between the sheets is increased, and the horizontal and vertical joints are processed silicone sealant. There are 3 types of roofs from a profiled sheet:

- Low-slope. If the angle of inclination of the roof from a profiled sheet is less than 14 degrees, to increase the waterproofing properties of the coating, the horizontal and vertical overlap is increased to 20 cm, a frequent or continuous crate is made, and a membrane material is used to protect the rafters from moisture. Each sheet of material overlaps the previous one by 3 waves, which reduces the usable area of the material, increasing consumption.

- Medium slope. If the slope of the roof is 15-30 degrees, then the overlap between the sheets of corrugated board is 15-20 cm, which corresponds to 1-2 waves. Such an inclination of the slopes allows you to save money on roofing work by increasing the useful area of \u200b\u200bthe sheet.

- Steep. If the roof slope exceeds 30 degrees, when installing corrugated board, a minimum overlap of 10-15 cm is allowed, corresponding to 1 material wave. At the same time, for flooring, you can use a lattice crate with a step of up to 25 cm.

Please note that when laying a profiled sheet, a clear pattern can be traced: the smaller the angle of inclination of the slopes of the structure, the more overlap between the sheets is needed to protect the roof from leaks at the joints and tearing of the material by gusts of wind.

The dependence of the type of lathing on the slope

Industrial buildings are most often covered with a flat type roof, utility buildings are of a single-slope type, and residential buildings are of a gable, hip and four-slope type. Regardless of the type of roof structure, the coating must be laid on a reliable base that can withstand heavy loads and evenly distributes. The slope of the corrugated roof affects:

- If the height of the material profile does not exceed 20 mm, and the roof slope is less than 15 degrees, then a solid base and edged boards 2-3 cm thick are mounted to ensure reliable support.

- If the profile height is more than 35 mm, and the roof slope is also less than 15 degrees, it is allowed to install a lattice base, the step between the boards in which is 30 cm.

- If the height of the profile is 44 mm or more, and the roof slope exceeds 15 degrees, a edged board 2-3 cm thick, pinned in increments of 35-50 cm.

Please note that any corrugated roof, no matter how steep the angle of inclination of the slopes, requires a device drainage system, consisting of gutters, funnels, pipes, which is responsible for collecting and transferring rain or melt water to storm sewers.

Video instruction

The construction industry in our country has relatively recently used a profile sheet as a roofing material, although in Europe and America this technology has been widely developed back in the 80s of the last century.

Thanks to high technical specifications the material gained immense popularity in a short time.

Listing the main advantages, the material compares favorably in:

- Simplicity installation work.

- Lightness of individual sheets and ease of transport.

- Long operating period.

- High aesthetic design.

The device of a roof from a professional flooring

Decking the most convenient material for roofing installation. The operation of the entire building to a large extent depends on the level of the roof slope, it is profiled metal sheets, due to their design, that make it possible to lay the material with a minimum slope (from 8 degrees), according to SNiP.

This slope guarantees a normal runoff of rainwater due to the presence of stiffeners in the structure of the corrugated board.

In turn, a trapezoidal stiffener performs two functions:

- strengthens the material from mechanical stress;

- evenly allows the removal of water and snow from the total surface of the roof.

When equipping residential buildings, corrugated board is laid with a minimum slope of 12 degrees and an optimal slope angle of 20. Industrial structures can use a smaller degree of slope angle, but not less than 8.

The number of layers laid can change the slope limit, for example: a two-layer laying requires an increase in the angle to prevent the accumulation of moisture and other types of precipitation on the roof surface.

- For a tighter fit joints, various sealants are used that maximize protection against moisture penetration.

- If the angle of inclination during installation of the roof less than 14 degrees, overlapping of the lower sheets must have a margin of at least 20 cm.

The design feature of the roof includes the installation of sealing elements that provide sealing of the ridge with the valley part. Seals prevent moisture and rain from entering the joints.

What determines the angle of the roof?

Roofers-builders of mountainous areas are considered to be the real professionals. Those mechanical loads in the form of snow that buildings in mountainous areas experience during operation are not subjected to any building in other regions with more gentle loads on the roof.

Increasing the slope requires additional expense roofing material, but the 45-degree slope angle fully ensures the removal of snow from the surface.

The so-called self-cleaning roof has its pros and cons.

The advantages are definitely:

- Increase the operating period of the entire roof structure.

- Large attic spaces.

The main disadvantage of these types of roofs is:

- Using more material: lathing, rafters, roofing.

- Increased load on the roof from strong winds, hurricanes.

The angle of inclination of the roof also depends on whether the attic space is being used. The non-exploited type of roof, in fact, is the overlap of the floors of buildings on which the roofing material is attached. An unused roof does not require a gap between the ceiling and the roof.

- Choosing flat type roofs, developers benefit both in the economic ratio and in the speed of installation work.

- Minimum Tilt Angle used in regions with open areas where strong air currents are observed, in this case the wind load on the roof surface is significantly reduced.

Advantages of profiled sheet as a roofing material

The profiled sheet has become popular for several reasons:

- long operational period due to the features of the processing of the material for corrosion protection;

- low price;

- beautiful design look;

- ease of installation;

- convenience during transportation and storage.

Manufacturers have taken care of the variety of produced material. Some products have several types of coatings that maximally protect the profiled sheet from corrosive damage in an aggressive environment and mechanical damage from loads.

A variety of colors makes it possible to select the material to create original design structure.

The steel profiled sheet, which is used in roofing, has the largest metal thickness (from 0.5 mm), this factor is an important advantage of the material: the sheet, due to the presence of stiffeners, is able to withstand a large weight load.

The technology of laying profiled sheets on the roof

The profiled sheet is a galvanized metal sheet, which has stiffening ribs in the form of a trapezoid evenly over all surfaces. Thanks to this design feature, the material becomes more protected from mechanical damage, while it has a relatively light weight, which in itself facilitates the installation process.

The roof can have several types of laying:

- shed (the easiest installation option);

- many pitched (two or more slopes).

Steel sheets can be processed during installation, this feature allows laying roofs of any complexity and configuration.

When choosing a material, the type of roof construction is taken into account. brand C8 and above it is suitable for installation of a roof starting from 15 degrees of a slope of a slope. The maximum sheet length can reach 12 m, with a width of 1250 mm and a thickness of 1.5 mm.

On sale there are sheets with ready-made gutters for draining water. Polymer coatings are additional protection from corrosion damage, this material is more expensive to purchase, but its operational age is much longer.

The most suitable material for installation is marked NS, N, S having a corrugation height of at least 21 mm, trapezoid or wave shape and a metal thickness of 0.8 mm.

Step by step installation of corrugated board is as follows:

- Laying in progress layer of waterproofing material.

- To ensure correct ventilation material is fixed with long wooden slats.

- For roofs, which will be further be operated (residential buildings with attics and warm ceilings), heat-insulating material is laid.

- Observing the desired slope angle, the crate is installed.

- On the crate with the help of self-tapping screws or special screws mount corrugated board.

Factors affecting the slope of the corrugated roof

Largely the slope of the roof is selected from the region where the building is being built. When laying a high roof in places where squalls and strong winds are observed, the roof structure will quickly fail due to high mechanical loads.

Increased dynamics of loads can damage and even destroy corrugated roofing, while the minimum selected angle of inclination will perfectly fulfill its functions.

In mountainous areas, where there is a large amount of precipitation in the form of snow and rain, on the contrary, the angle of inclination of the roof is the most advantageous option. Mechanical loads are also large, but they are of a different nature and a roof with a small slope will not be able to provide reliable living in the building for a long time.

Calculations for calculating the angle of inclination

Professional roofers never do their job by approximation.

Everything related to the roof has clear conventions, the same rule applies to calculating the desired angle of inclination.

When designing roofs, engineers use special formulas that take into account the size of the house, operating conditions and individual factors (the use of warm ceilings, attics).

With the help of a special device, an inclinometer, the material is installed on site at the right angle, the smaller the angle of inclination of the roof, the better ventilation should be.

Advantages and disadvantages of minimum

roof slopes from profiled sheet

Like any technology, the minimum slopes of corrugated roofing have their pros and cons.

Like any technology, the minimum slopes of corrugated roofing have their pros and cons.

A significant plus flat roof is the minimum amount of materials and easier and faster installation.

The weakness of the technology is cold ceiling, unusable and poor soundproofing.

A small slope angle slows down the vortex flow of air between the crate and waterproofing, improperly organized ventilation ducts contribute to the accumulation of moisture under the sheets, which will subsequently accelerate the destruction of the base.

Experienced roofers in their work try not to make mistakes. When installing the roof, every little thing is taken into account, and therefore a few tips for novice craftsmen can come in handy.

How to fix the profiled sheet on the roof

The laying of sheets starts from the maximum height and the entire row of sheets must have a clear mounting line. Installation of corrugated board is carried out with special self-tapping screws to the roof sheathing.

The self-tapping screw has a sharpness according to the principle of a drill for metal, and under the cap there is a rubberized sealant, which perfectly seals the fastener place.

When laying a new row of profiled sheets, it is possible to overlap up to 20 cm. Slopes of less than 12 degrees require special treatment of the joints with sealants.

Which brand of profiled sheet to choose for the roof

The profiled sheet has a wide range of applications in construction, so when choosing a material for roofing, you need to know that not all grades of profiled steel sheets are suitable for roofing.

Sheets with markings NS, S, N most suitable for mounting. You need to choose the sheet thickness from 0.8 mm, with the designation S, H or NS 8 and ending with a maximum thickness of 20 mm.

The profiled sheet can differ in the quality and quantity of protective coatings. Metal treated with special polymer compounds is the most durable and provides maximum protection.

Features of laying corrugated board

The corrugated board is well protected from corrosive damage, but nevertheless, one of the features of the installation is to provide a structure ventilation ducts, which prevent the accumulation of moisture under the sheets.

During installation work, it is categorically not advisable to use a grinder for circumcision. Heating the metal contributes to the loss of those valuable qualities that provide protection against corrosion.

The top row of sheets is laid with the calculation of a 4 cm indent from the edge of the cornice strip. The side parts of the roof are equipped with a wind corner. Slopes exceeding 16 degrees do not require the installation of seals.

Self-tapping screws equipped with special neoprene seals should not be tightened too much, this will destroy the integrity of the material.