You can improve the appearance of a house or any other extension by installing siding, moreover, it perfectly protects the walls from precipitation and wind blowing. This facade material is also used for cladding industrial buildings.

Siding is a practical and popular building cladding material. It is produced in the form of panels from 3 to 4 meters long, each of which has a latch-lock and an edge with holes for fasteners. Siding has good performance characteristics and aesthetic appearance. Of the positive qualities, it can be noted:

- makes the appearance of the building more beautiful and neat;

- thanks to a large selection of panels, the house can be given an individual style;

- high-quality siding has a service life of more than 30 years;

- installation can be done independently;

- is a safe material;

- when dirty, it can be easily cleaned with water and detergent.

Low-quality and cheap siding burns out under the influence of the sun after 2 years, since a small amount of titanium dioxide is added to it during production.

Finishing panels are available in a variety of textures, and come in a wide range of colors. Siding is produced in several types:

- Metal;

- Vinyl;

- Basement (fiber cement);

- Acrylic;

- Wood.

Let's take a closer look at each type:

- Vinyl siding is made of polyvinyl chloride and is outward appearance can copy finishing materials from stone, wood and brick. The panels are lightweight and resistant to mold and decay. The material is non-toxic and not damaged by pests. Vinyl products do not conduct electricity and are inexpensive, but not resistant to mechanical stress.

- Acrylic siding is a new finishing material, and in terms of technical parameters it is almost the same as vinyl siding. At the same time, it is very durable, has a more resistant coating to the effects of ultraviolet rays. The panels have a long service life and do not deform from high temperatures... It is also resistant to aggressive substances and non-flammable. Acrylic siding has one drawback - high cost.

- Metal siding is available in steel, aluminum and galvanized steel. This material is strong, durable and environmentally friendly. The panels do not change their original shape when the temperature drops and are resistant to oil and chemical substances... Mold cannot grow on its surface and pests do not eat it. Have metal siding there are several disadvantages. Rust will form on the panel when the protective coating peels off. There is a lot of noise when it rains. Metal siding is more expensive than vinyl siding.

- Wooden siding or facade lining is the most environmentally friendly material and has excellent thermal insulation performance. It is produced from coniferous and larch wood species. To prevent the panels from darkening and cracking, a protective coating is applied to them. The price of the material depends on the type and type of wood.

- Fiber cement panels are made from high quality cement, cellulose fibers and sand. Outer side the slab has a special coating that protects against moisture and sunlight. The material is non-combustible, and it also does not rot and mold. Fiber cement siding is resistant to mechanical damage and deformation. Does not contain harmful substances and is environmentally friendly. The service life is 25-50 years, depending on the manufacturer and external conditions.

Installation of battens with waterproofing and insulation

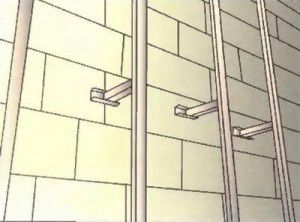

Before installing the siding, you need to make a reliable frame. The lathing can be made of wooden beams or metal profiles. It is fixed to the walls with brackets. The racks of the lathing are fixed in the opposite direction of the siding, that is, if the panels are mounted horizontally, then the lathing is made vertically, and vice versa. The distance between the elements in the structure depends on the weight of the siding - the heavier the material, the more often the racks are attached.

Step-by-step instructions for making the lathing:

- The surface of the walls is prepared, drains and all protruding parts are removed.

- If necessary, the walls are primed, wooden surfaces treated with an antiseptic.

- Using a level and a plumb line, places are outlined for attaching the suspensions. They are placed every 40 cm, they retreat from the edges of the walls by 15 cm, from the inner corner - 10 cm.

- Drill holes, insert dowels and mount U-shaped brackets.

- Bars are fastened along the edges of the wall, a rope is pulled between them.

- The rest of the vertical beams are mounted.

- With a step of 40 cm, horizontal metal profiles are installed.

- Above the plinth, above and below the windows and doors, using the “crab” connector, the horizontal elements of the battens are fixed.

- Mineral insulation is laid between the racks and under the crate; an overlap is applied at the joints. Attached to the wall with umbrella dowels.

- Mineral wool and crate are covered with wind and vapor barrier insulation. The edges of the film are stacked on top of each other and glued with construction tape. It is fixed to the crate with double-sided tape and counter-rails.

You can insulate the walls immediately after installing the U-shaped brackets. The heat-insulating material is put on the suspensions and fixed with umbrella-type dowels, after which it is covered with waterproofing, and the lathing is mounted for installing the siding.

For regions with a warm climate, thermal insulation is not done, and for cold zones, the thickness of the insulation should be at least 15 cm.

Installation of the starter bar

Before installing the starting strip, ebb tides are installed. They are fixed with self-tapping screws with a distance of 40 cm between them. When joining, the ebb tides are placed on top of each other. The overlap width is at least 2.5 cm. A building level is used to indicate an even angle.

The starting or starting bar refers to the load bearing elements. Installed from the top edge of the ebb or at the very bottom of the wall. The first siding sheet is being installed on it. The initial bar is fixed by checking the level, since the evenness of the entire wall cladding depends on its installation.

Installation of the starter bar:

- from the lower border of the future sheathing retreat upward by 4 cm;

- using a level, they make marks on all vertical posts of the crate or make notes on the wall if there is no frame;

- the initial plank is set with the upper edge to the marks;

- fixed with self-tapping screws in the middle of the factory holes;

- the starting strips are attached so that the distance between them is 0.5 cm (this gap is necessary for thermal expansion);

- the same distance should be from the edges of the corner elements or the width of the corner profile plus 12 cm.

What is the J-profile for?

- The J-profile is a versatile, load-bearing siding trim element. It can be regular, arched (flexible) and wide.

- A regular J-profile is required at the end of a cladding row at the end of a wall, for sheathing the edge of an eaves, or for replacing a finish panel.

- Wide is usually used to decorate door and window openings.

- Arched is used along the edge of an arch-shaped opening. The panel has notches where cuts are made at the required distance, so that it can be bent at the desired angle.

- J-profiles are fixed to the walls with nails or self-tapping screws.

How to fix the siding

Fastening of siding is done on the facade of the building or on the lathing. Fastening methods depend on the type of facing material:

- Vinyl panels should only be fastened to the factory holes.

- It is recommended to use galvanized fixing hardware for wood cladding.

- The fastening of the elements should be done straight and straight, in the center of the factory hole.

- Fastening the siding to each other, they push it from the bottom up so that the upper panel snaps into the lower lock.

- When installing the slats, you need to leave a gap of 2 mm between them and the lathing to expand the cladding during temperature changes.

Installation of internal and external corner strips

Corner panels are load bearing elements. Attached after the starting profile. Designed to close and secure the edges of siding, also serve as guides.

Installation of corner strips:

- mount the panel so that its lower part protrudes 0.5-0.7 mm above the starting bar, and the upper edge does not reach the cornice by 5-7 mm;

- begin to fix the profile from top to bottom;

- the first self-tapping screw is screwed into the upper part of the factory hole, the rest of the fasteners are located in the middle of the holes;

- the distance between the screws is 20 cm;

- to lengthen the corners, the holes for fastenings are cut off at the top profile to a length of 34 mm so that the strips overlap each other by 25 mm, and the remaining 9 mm are left for a gap;

- if the starting strips are located close to the corner, then at the corner profile the edges of the nail fasteners are cut to the height of the starting strip;

- internal and external corner strips are installed using a plumb line and level.

How to lengthen siding strips

When the siding is shorter than the length of the sheathing wall, to lengthen the panels horizontally, put connecting strip... The connecting profile covers the joints of the siding, which makes it more durable, protects against precipitation under the cladding. In addition, this way the appearance of the facade will look more beautiful and look like one whole.

You can also lengthen siding panels using the "overlap" method. The profile sheets should be staggered, avoiding butt joints at the same level in a row. The overlap length of one panel on another must be at least 5 cm, with the obligatory coincidence of the factory holes for fasteners.

Installation of H-profile

H-profile refers to additional load-bearing elements. Used to connect two horizontal sheathing panels if the wall length more size facing material. It is also used when connecting soffit (cornice) siding.

The fastening of the connecting strip starts from the top of the wall. The first fasteners are made at the top of the hole, the subsequent screws are screwed in the middle of the holes. The H-profile from the eaves should recede by 0.5 cm, and be 6 mm below the starting bar. On both sides, the connecting profile has a distance of 0.6 cm from the starting panels, that is, it is located between them.

During installation, the siding is not inserted into the H-profile until it stops, but so that a gap of 5-6 mm remains for thermal expansion.

Installation of ordinary siding panels

For an even and neat finishing of the facade of the building, it is necessary to use a level, the length of which must be at least 80 cm.

The end side of the first siding panel is inserted into the corner strip, and the lower part is inserted into the initial bend-lock and snapped into place. After that, if necessary, pull it up to level the horizontal row. Twisting the fasteners on the panel is done from the center to the edges. Leave 5 mm between adjacent strips for thermal expansion.

Fasteners must not be fully screwed in. A gap of 1-2 mm is left from the screw head to the panel. You cannot pull the profile up after the lock connection on the starter bar clicks into place.

Subsequent rows of panels are installed in the same way - one side of the siding is placed in the corner groove, and the other in the H-profile or in the opposite corner. The installed panel is snapped into the lock of the previous one and screwed to the crate.

Facade cladding with siding is mounted to the top of the wall, but so that there is room for the installation of the finishing strip and the last profile.

Laying the finishing siding strip

The finishing bar is decorative element which is used for a beautiful and airtight finish on the top edge of the last panel. Install with the factory mounting holes facing down and the panel lock facing up.

Finishing strip installation procedure:

- the plank is mounted with screws at the very top of the wall, under the eaves;

- the distance from the top of the finishing strip to the installed panels is measured, and 0.3 cm is subtracted from the result; if the width of the profile sheet is greater than the distance, then the upper part is cut off from it;

- at the cut panel (without the upper part), holes are made every 10 cm with perforating pliers;

- at the prepared strip, the lower part is inserted into the lock of the previous profile, and the upper part is inserted into the lock mount of the finishing panel and latched into place.

Fasteners are screwed onto the finishing strip through 3-5 holes and in their center.

How to get around windows and doorways with siding

Before siding, the openings of windows and doors are trimmed with special additional elements (platbands). Perimeter inside windows (doors) fix the slats to which the finishing profile is screwed.

At the upper and lower near-window strips, the edges from the inner side are cut by 2 cm, and bent in the form of "tongues". The upper and lower platbands are inserted into the groove of the finishing one, then fixed with screws to the crate. When installing the side window strips, the "tongues" are wound inward.

If the siding panel does not fit in width under the window or above the window (or door), it is shortened to the required depth along the width of the opening. At the place of the cut, holes are made for fasteners, which should be the same size as the factory ones. Then the siding panel is slipped under the window element and fixed. An ebb is installed at the bottom of the window opening, the upper edge of which rises from the window along its entire length. The width of the window sill should be 5 cm larger than the opening.

Above the window (door), the profile is mounted in the same way. For wall cladding on the side of the openings, the panels are cut to the required length. Then they are brought under the platbands.

When the wall cladding is made with highly embossed siding, for example, a block house, then the installation of window slats is done after the panels are installed.

Gable trim

At the final stage, they start facing the pediment. If the attic will be used for living quarters, then the pediment is insulated.

First, the roof overhangs and the end part of the roof are prepared. Remove old cladding, ebbs and wind boards. The roof material is trimmed so that it is flush with the front overhangs. The lathing for the siding of the pediment is made in the same order as on the walls.

Installation of siding on the pediment:

- if the wall of the house and the pediment are separated by the cornice, then ebb planks are mounted;

- along the perimeter of the pediment, J-strips are fixed or from below the starting one, and from above - the finishing one;

- corners are made from a metal profile and strips of outer corners are installed;

- since the shape of the pediment has an angular slope, a siding trim is used as a template to apply cutting lines to it;

- the connection of the panels is made with an overlap or with the help of an H-strip;

- the top is a ridge siding sheet, fixed from above directly through the panel, it is better to drill a hole in advance.

The cornice is finished with a special facing material - soffit. For the installation of panels, the edges of the cornice are sheathed from the inside with slats. J-bars are attached to them. Soffit siding is flexible enough, so it is easy to install with a slight downward bend and fit into the grooves of the J-strip. A click is heard when the panel is inserted correctly. The distance between them is 0.2-0.3 cm for thermal expansion. The cladding of the building is completed by the installation of roofing strips - drip planks. Placed on the outside of the slopes.

You can do the installation of siding with your own hands. The main thing is to strictly follow the manufacturer's instructions and follow all recommendations. Buying building material should be done in one batch at once, so that it is enough to finish all the walls, plus 5-10% more than the calculated amount (for fitting). Complementary elements are purchased from the same manufacturer.

- an excellent material for house cladding. At its affordable cost, it has many positive performance and technical characteristics.

You are offered detailed instructions for self-assembly siding. The guide is universal. Following its provisions, you will be able to complete any finishing that involves installation on a crate: fiber cement, wood, metal, vinyl, etc.

We mount the crate

Siding is best attached to a pre-assembled batten. We work in the following order.

The first stage - choose the material

The frame can be assembled from a wooden bar or a metal profile. Metal products are stronger and more durable. In addition, metal lathing is much easier to attach to an uneven base.

Find out, as well as familiarize yourself with the calculation algorithm with an emphasis on possible nuances.

Installation of profiles is carried out in half-meter increments. Hangers are used for wall mounting. This technique will allow you to level the surface drops and fix the frame elements at the level.

Wooden lathing is cheaper. When choosing this option, pay attention to the condition of the wood. It is prohibited that:

- the material has exfoliated;

- was deformed;

- had cyanotic spots and traces of rot, etc.

The elements of the wooden crate must be impregnated with a fire retardant and antiseptic. If the house is built from wooden elements, the walls should also be treated with the listed preparations.

The second stage - we prepare the base

The lathing is easiest to attach to a flat base. First of all, we remove any details that might interfere. These are all kinds of tiles, bars, platbands, gutters, etc.

The third stage - set the guides

Siding is best mounted horizontally. In this case, we fix the bars or profiles of the lathing vertically.

We use nails or self-tapping screws to fasten the guides to wooden walls. If the house is built of concrete blocks or bricks, we fix it with dowels, having previously drilled holes for them in the wall of the house.

We level each rail.

Important! If you plan to do it outdoors, it is best to attach the siding battens after all insulation work has been completed. In this case, there will be two battens: for insulating materials and for cladding. In this case, the slats of the two frames must be placed parallel to each other.

You can, of course, try to install the insulating layers after attaching the siding battens, but this is not very convenient.

We mount J-profiles

The starting guides must be perfectly secured because the quality of the entire cladding depends on the correctness of their installation.

First step. Take the level and find the lowest point on the crate. We retreat from it upwards 50 mm and put a mark. To do this, screw a self-tapping screw into the rail a little.

Second step. We consistently move around the building and continue to put marks with self-tapping screws to fix the starting profiles. We also screw in self-tapping screws in the corners of the house.

Step three. We stretch the ropes between the corner marks.

Fourth step. We mark on the rails the boundaries of the installation of the corner profiles. We take the profile itself, apply it to the corner of the frame structure and place marks along the edges with a pencil.

Important! Leave a 1-cm gap between the profiles to compensate for thermal deformations.

Leave a gap between the starting guides and the nail strips.

In order not to make a 6 mm indent, you can cut off parts of the nail strips so that during temperature changes they do not rest against the J-profile.

Important! The starting profiles must be mounted strictly horizontally! Correct deviations as long as necessary.

If you set the guides with deviations from the level, the siding will also warp. It will be extremely difficult to fix this in the future.

Profile mount prices

Profile mounts

We install external corner profiles

First step. We mark the spotlights. We need to see where the edges of these elements will be in the future.

Second step. We apply a guide to the corner of the frame. We do this with a 3 mm gap to the soffit or roof. We fix the profile with self-tapping screws.

Place the lower border of the element 0.6 cm below the edge of the starting profile.

Step three. We check the verticality of the installation. In the absence of deviations, we fix the bottom, and then - the rest of the places. Experts advise against placing fasteners in corner pieces too often.

If the house is taller than 300 cm, the profiles will need to be superimposed one on top of the other. To do this, trim the top profile. As a result, a 9 mm gap should remain between the strips of the abutting elements. When laying the elements, we maintain an overlap of 2.5 cm.

Important! We dock the profiles at the same level on each side of the house.

If the base has a protruding structure, we shorten the profile so that a 6 mm gap remains between it and the base.

Useful advice! Instead of the corner profile, it is allowed to install 2 J-elements (starting). This will save you money. But this solution also has its drawback - the corner will not be as tight as when using a special corner profile. Having decided to use this method, first glue the wall around a similar corner with a strip of rolled waterproofing material.

We mount internal corner profiles

The installation procedure for these elements does not differ significantly from the technology for arranging external corners - we leave an indent of 3 mm between the profile and the soffit, and lower the lower end of the profile by 0.6 cm below the J-bar.

If from below there is a protruding base or other element that is knocked out of the general level, then we also leave a 6 mm indent between it and the profile - it is impossible for the profile of the inner corner to rest against it.

There are 3 methods for arranging interior corners, see the picture.

If the wall height is more than 300 cm, we perform the splicing of the profiles. The technology is the same as for the arrangement of external corners.

Leave a 9mm gap between the planks, carefully trimming off excess material. The overlap of the upper element to the lower one is 2.5 cm. We install the fasteners in 4-cm increments, placing them strictly in the center of the holes intended for this. The exception is the highest point. Here, the fasteners need to be installed at the top of the hole.

We mount frames for openings

For most inexperienced craftsmen, difficulties arise precisely at the stage of framing and doorways. The order of work will differ depending on how the openings are arranged in relation to the plane of the wall.

Openings in the same plane with the facade

In this case, we do the following.

First step. We carry out waterproofing of openings.

Second step. We attach platbands or J-profiles to the openings. We equip each opening using 4 platbands: a pair of vertical and a pair of horizontal ones.

Step three. We connect the profiles.

To make the connection of the platbands as accurate as possible, we do this:

The platband below is connected in the same way, only the bridges will need to be cut and bent on the side elements for their further overlay on the profile below.

The openings are recessed into the facade

When installing near-window profiles, we work in compliance with the same recommendations as when installing platbands, i.e. create cuts on the profile corresponding to the depth of the opening, and then bend the bridges and insert them into the finishing elements.

Do not be too lazy to understand the principles of bending such bridges. We make them so that they cover the joint of the cladding elements. As a result, moisture will not be able to penetrate inside.

We mount the first panel

We start cladding with the least visible wall of the building. So we can practice and work out all kinds of inaccuracies.

First step. We insert the first cladding panel into the corner profile and into the lock connection of the starting strip.

Important! Leave a 6 mm thermal gap between the first cladding element and the lower part of the corner profile lock.

Second step. We attach the panel to the crate.

It is important to respect the dimensions of the technological indents. If the cladding is carried out in warm weather, we maintain a 6 mm indent, if in cold weather, we increase the gap to 9 mm. When setting the trims of the panels, the indents can be reduced.

Expanding the panels

We build up cladding elements with an overlap or with the help of an H-profile.

When fastening panels with an overlap, you must first shorten the cladding panel locks and fastening frames so that the resulting overlap has a 2.5 cm length.

Installation of the H-profile is performed similarly to corner elements - at the top we retreat 0.3 cm from the soffit, lower it by 0.6 cm in relation to the starting profile.

Important! Leave a 6 mm gap between the H-profile and any obstacles on the house.

We mount the rest of the siding

We continue to clad the house with siding. The technology of operation is similar to the procedure for fixing the first panel.

Important! Every 2-3 rows we check the horizontalness of the cladding using a level.

Having reached the opening, we remove the unnecessary piece of the panel falling on the opening.

We provide reliable fastening of the panels with the help of "hooks". For this we need a punch.

We mount an additional finishing profile at the bottom of the opening. It will allow you to align the cladding on the plane.

Mount under the roof

We attach the J-profile under the roof structure.

We work in the following order.

First step. We measure the distance between the lower part of the finishing element lock and the lock of the penultimate cladding panel.

Second step. Subtract a 1-2 mm indent from the resulting measurement.

Step three. We mark out the whole panel, cut off its upper part with a lock connection.

Fourth step. Create "hooks" at the top of the element in 20 cm increments. To do this, we make incisions and bend them to the front side.

Fifth step. Insert the trimmed element into the penultimate siding panel. With a slight upward movement, we snap the inserted element into the lock connection of the finishing profile.

We mount the pediment

We sew the pediment around the perimeter. All fasteners, except for the top one, are installed in the center of the holes. The upper fastener is installed at the top of the hole. Sheathing can be done both with profiles for arranging internal corners and with a starting profile.

The installation procedure is the same as for fastening wall panels... We trim the edges of the elements and connect them with the locks of the receiving profiles. Remember the 6mm spacing when installing in warm weather and 9mm when doing work in winter.

We attach the last element of the gable trim directly through the panel material - this can only be done here.

The cladding is complete.

Find out how and also consider the calculations and step by step guide, from our new article.

In order for the decoration of the house with panels to be as successful as possible, you need to know certain subtleties of performing such work. There is a list of general guidelines for any siding, as well as individual tips for panels made from a particular material.

Now you can do it yourself at the highest level.

| Name (model) | Advantages | Length x width x thickness, mm | Qty in a package, pcs |

|---|---|---|---|

| Vinyl Siding "Kanada Plus" | 1. Staining in dark tones is performed using the "Cool Color" method (heat absorption), which implies the use of masterbatches. 2. Excellent appearance remains unchanged even when exposed to high and low temperatures, the range of which ranges from -50 ° C to + 60 ° C. 3. Retains shock resistance, even if the ambient temperature drops to -20 60 ° C. 4. Not subject to microbiological corrosion (fungi, mold). | 3660 x 230 x 1.1 | 20 |

| Acrylic Siding "Kanada Plus" | Among other useful qualities of Kanada Plus acrylic siding, it is worth highlighting: Increased resistance to direct UV rays; Excellent tolerance to acidic and alkaline solutions, as well as to various fats; Good washing tolerance with chemical detergents; High degree of deformation resistance (perfectly tolerates temperatures up to 75 ° -80 ° C). | 3660 x 230 x 1.1 | 20 |

| "Alta-Siding" - Vinyl Siding | "Alta-siding" is: one of the safest finishing materials in the Russian market; frost resistance and the ability to maintain strength even at very low temperatures (from -20 to -60 ° C); resistance to significant temperature changes and environmental influences; durability: the service life of "Alta-siding" is up to 30 years; resistance to aggressive substances (for cleaning siding you can use detergents); not susceptible to mold infestation. | 3660 x 230 x 1.1 | 20 |

| Facade metal siding INSI | Siding "INSI" is made of galvanized steel, covered with a layer of polymer composition, which means it inherits all the advantages of this material: resistance to temperature extremes (-50 ° С - + 80 ° С) and mechanical damage; long service life with preservation of the original properties (about 50 years); environmental friendliness; incombustibility; the ability to mount both horizontally and vertically; protection of the building from overheating (in the ventilated facade system); and when choosing one of the two new colors (alder or rosewood) - a complete imitation of the appearance. | Length up to 6000, width up to 200, thickness 0.5 | - |

Happy work!

Siding prices

Video - DIY siding installation

One of the most reliable building materials siding is used to protect the entire construction site from any external influences. However, no matter what qualities this material has, if the installation of siding is not done according to technology, then its protective properties can be reduced to zero. And, despite the fact that this material in its structure should protect the structure from atmospheric precipitation, exposure to ultraviolet radiation, noise and other adverse phenomena, the slightest violation during installation leads to the penetration of harmful substances into the premises.

In this article we will talk about installing siding with our own hands, we will give detailed instructions for dummies, as well as accompany all photo and video materials.

For cladding any structure with siding, tools and some equipment are needed. First of all, these are screws and nails.

For cutting and fasteners, you will need a hammer, a level, a tape measure, a plumb line, a square, a pliers-puncher, a hacksaw and a circular saw with fine teeth. If we are talking about the installation of metal siding, then you still need to purchase metal scissors for trimming panels in the corners. When installing vinyl siding, a sharpened ordinary knife is used for cutting in the transverse direction, and for transverse cutting - circular saw... For eye protection, experts recommend wearing safety glasses.

Instructions

The process of laying vinyl siding will be described step by step below. Following simple tips and recommendations, you can do this work without being a specialist.

The first step is the correct cutting of the material, in order to use it as economically as possible, and to avoid mistakes in the layout of the panels. For this, a plan (drawing) is drawn up, which allows you to correctly distribute the material over the entire surface to be covered.

Base for siding

Before starting the installation of panels, a crate is arranged on the facade of the building. This is done in all cases, except when a wooden building is faced with panels. For the manufacture of lathing, wooden blocks, edged boards, metal profiles are used.

The effectiveness of installation depends on the correctness and care with which the crate will be filled, that is, how strong the resulting base will be.

So, installation basement siding(as, by the way, and any other) will be carried out correctly if all the irregularities of the wall or lathing are smoothed out. The fact is that in the final version, the siding will only expose all the irregularities and flaws in the preparation. For best quality works, horizontal cladding with panels is performed on a horizontal crate, and vertical mounting perform on the vertical, respectively.

If the cladding is carried out with the use of insulation, then it is recommended to use roll insulation as an insulating material, and the use of loose materials contributes to the deformation of the surface.

The basic rule that the installation instructions require is the formation of a gap between the panels, since the siding is subject to thermal expansion and contraction, and if this condition is not met, the facade may swell and warp. The panels are fastened with self-tapping screws or galvanized nails through the corresponding rectangular slots.

The nails should not be driven very tightly into the middle of the holes, in which case the fastening of the panels will be strong and reliable. Installation by hammering nails directly into the panels leads to their destruction, therefore it is not recommended.

After fixing the panels, they should "walk" freely in the horizontal direction. They overlap by about 25-30 millimeters.

To begin with, all panels must be left outside for two to three hours so that they "get used" to the outside temperature. When installing siding in winter in cold weather, the gap between the panels must be increased at least twice, that is, it should be about 10 millimeters. In this case, the linear expansion coefficient of the siding will be maintained, and the panels will create strong and reliable protection of buildings and structures.

The first step that the instructions require is the installation of the initial elements. These are starter profiles, inner and outer corners, and special J-profiles. Then you can start the direct installation of the siding.

The starting profile is the element that starts the installation of all panels and to which all other panels are attached. For fixing panels in hard-to-reach places, for example, at the joints of cornices with walls, along the perimeter of window and door openings, J-profiles are used. With the help of this profile, facades can be given any, most bizarre look, since it allows fastening taking into account all design features structures. Another element used for ennobling facades is the finishing strip. The facades in the top row are sheathed with it, thanks to which the surface looks even and neat.

When fixing the panels vertically on the outer corners of the building, the installation technology assumes finishing, the so-called outer corners, this allows you to ensure a neat appearance of the corner joints.

The inner corner plays the same role, only it provides carefully masked joints of the inner corners of buildings.

Siding

Sheathing with panels is started from those places in which the maximum load is expected to be applied to them. These are doors, gates, window openings, etc. This allows all other connections to be isolated from these places. All ordinary siding panels are fastened with a lock connection. That is, the lower lock of the previous panel (top) should be fastened to the upper lock of the next panel (lower). Vertically, the cladding is made with an overlap, thus having the ability to adjust the dimensions of the sections, both in height and in width.

Ground siding

The work of installing basement siding is simple, so you can do it yourself. First you need to carry out preparatory work. The final result depends on their quality.

The standard size of the base / plinth panel is 500 × 1200 mm. Their fastening is carried out in the same way as for conventional sheathing siding. Other sizes can also be found, for example 220 × 3000 mm. Such dimensions require the installation of an exclusively vertical crate.

In some cases, decisions are made on the plinth siding of the entire facade of the house. Additionally, the wall can be insulated.

The principle of making the frame is as follows:

- The lathing for the basement is best made from a metal profile. Wooden beams dampness may accumulate in close proximity to the ground, as a result of which it will become unusable.

- Based on the climatic conditions, you independently determine the height of the base. If you live in an area where the ground is very freezing, then the crate should be raised from the ground level by 150 mm. If it does not freeze, then you can start installation directly on it.

- In the manufacture of the battens, both horizontal and vertical guides should be installed. So, the step between the vertical is 900 mm, and between the horizontal - 450 mm.

In the process of assembling the lathing frame, be sure to use a level. Otherwise, the installation of the basement siding will go uneven.

When the lathing is done, you can start installing the basement siding. The work is the following sequence:

- The starter bar is mounted horizontally.

- Inner / corner elements are installed on the corners.

- For fasteners, self-tapping screws with a press washer 4–5 cm long are used.

- There should be a gap of up to 1.5 mm between the screw head and the panel. This backlash will allow the panel to move without difficulty as it expands.

- At the joints in the corner of the building, thermal gaps of up to 10 mm should also be left. To make them invisible, they need to be closed with a platband corner.

- Siding installation starts on the left side. So, if it has an imitation of natural stone or brick, then the panel must be cut from the left side so that an even edge is obtained. After that, the cut edge is inserted into the casing corner and placed on the starting profile. Each subsequent panel fits strictly into the groove. When it comes to the opposite corner, the right edge of the element is also trimmed and inserted into the trim.

To increase the thermal insulation qualities of the house, the installation of siding can be done with insulation. Let's consider the peculiarity of facade insulation using the example of a wooden house. Having carried out the installation of siding with insulation, you can achieve 3 goals at the same time:

- Renovated facade.

- Thermal insulation.

- Moisture protection.

But for the insulation to be really effective, the selected material must meet the following criteria:

- Easy to install.

- Maintaining the original form.

- Resistance to chemical and biological compounds.

- Environmental friendliness.

- Long service life.

- Low rate of thermal conductivity.

The choice of insulation for siding is also influenced by two factors: the humidity of the air in your area and the wind rose.

Insulation types

There is a wide selection thermal insulation materials for the facade of a wooden house. For example, if a roll insulation is chosen, then the layer should be from 3 to 20 mm. Its fastening is carried out with special glue. You can also use mineral or basalt fibers, which are produced by slabs. Mineral wool and foamed polyethylene are very popular. Styrofoam is also often used. The strength and effectiveness of this material has been tested over time.

Most often, mineral wool is used to insulate the facade for siding. This material retains its original shape and is ideal for any type of siding. Minvata is produced in plates of the following sizes:

- 600 × 1200 mm.

- 500 × 1000 mm.

When choosing mineral wool to insulate the facade, make sure that its density is more than 80 kg / m 3.

V mandatory before laying the insulation, a layer of vapor barrier is laid (usually polyethylene or roofing material is used). It is necessary to prevent condensation between the insulation and the wall.

Vapor barrier when laying mineral wool is not needed. This insulation allows steam to pass through and does not absorb moisture.

When laying insulation, it is important not to leave a single gap or gap. It should envelop the entire facade of the building. The insulation itself is fixed on the already made crate. After this process, you can begin the installation of siding, the technology of which was written in this article.

- When installing any siding, it is necessary to avoid excessive tension of the panels when connecting each subsequent row to the previous one. Otherwise, it is fraught with swelling, deformation of a separate panel and disruption of the surface of the facades of buildings.

- The very last row of panels is laid after the finishing strip has been installed.

- Sheathing with panels is carried out from the bottom up, and is completed under the eaves of the structure.

- For the installation of siding at the location of objects, for example, pipes, holes are cut in the panels about 6 millimeters wider than the object.

- When siding the openings with J-profiles, it is necessary to set the upper and lower edges, respectively, above and below them. First, the J-profiles are installed, and in them the edges.

- When installing siding over the cornice, first install two or three finishing strips docked with each other (the bottom gap is kept within 3 millimeters).

Video

We invite you to watch a video about the installation of siding.

Photo

Below in the photos, you can view options for finishing houses with siding:

Scheme

The diagrams show some details of siding installation:

Any owner of a private house certainly wants his home to have an attractive appearance. What to do in order to change its appearance for the better? What material would be most suitable for this? The solution to these problems is quite easy today.

To do this, you just need to use modern building material - siding. It is quite affordable and has a number of advantages. In addition, you can do the installation of siding with your own hands. Such work does not require special skills and knowledge.

Innovative material

The word "siding" means a material intended for cladding various surfaces. Moreover, its main functions are aesthetic and protective. Once upon a time, an ordinary board was used for this, which was processed accordingly. And only much later, panels appeared on the construction market, which we call siding. They began to be produced from a wide variety of materials.

Siding has gained immense popularity due to its strength and lightness, durability and attractive appearance. But that's not all. Such panels are very convenient material for fastening. And this sometimes acts as a determining factor for those who are studying the question of how to mount siding in order to do the work with their own hands.

Usually, all panels, regardless of the raw materials from which they are produced, have certain dimensions. Their length reaches 6 m, the width ranges from 10 to 30 cm, and the thickness is 1-10 cm. Only the company that has a small production can have different sizes. Sometimes panels are made to order. However, in this case, their cost will be slightly higher.

The profile of the siding panels can be made in two versions. This is a "ship board" or "herringbone". They provide, respectively, a double or single fracture. But for editing, it does not matter.

All siding panels are covered with a protective layer, made either by painting or by applying a polymer film.

A huge advantage of this material is its excellent performance and maintainability. After the owner finishes the house with these panels, he will be able to forget forever about the impregnation of wood with special compounds, tint of the facade and other similar works. And to eliminate damage in the shortest possible time, it is enough to simply replace 1-2 products, which does not require any preparatory measures.

Siding classification

There are some types of panels designed for finishing individual buildings. This is the following siding:

- Wood. In appearance, it looks more like a traditional lining. It is called that - "glued lining".

- Vinyl. This siding is the most popular among the owners. individual houses and at the same time the cheapest. It is made from polyvinyl chloride or acrylic. Such panels imitate brick, wood or natural stone. Those who decide to change the appearance of their home should keep in mind that vinyl panels are easily damaged at very low temperatures. How to install this type of siding? The peculiarity of finishing with vinyl panels is that work with them is possible only when the weather is warm enough. In addition, due to the fact that vinyl siding does not reduce heat loss, the protected surface will require insulation.

- Aluminum. Such siding is distinguished by its low weight, as well as increased resistance to the negative effects of liquid media. It is perfect for facing large areas. In this regard, it can be used for high-rise buildings.

- Metal. This siding is the so-called galvanized. Protective layer it is made of polyester, pural or powder coating.

- Cement. This building material contains cement mixed with cellulose. For its installation, a sufficiently strong structure is required, since such a siding is heavy.

- Ceramic. This is one of the new types of panels designed for cladding buildings. Experts consider ceramic siding the best option among similar building materials in the middle price range.

- Basement. This type of panel is used to decorate the lower part of the building. Such products are quite durable. After all, it is the basement of the house that is most susceptible to temperature changes, when in summer it heats up from the blind area, and in winter it cools from soil and snow.

Tools

How to install siding with your own hands? The step-by-step instructions that will help the owner in these works, in the first paragraph, indicate the need to check the availability of the following tools:

- grinders or saws with fine teeth;

- scissors for metal;

- screwdriver and screwdriver;

- hammer;

- roulette;

- square;

- level (you can take a laser tape measure, which will greatly simplify the work);

- a stepladder that will allow you to reach the roof of the building.

Materials (edit)

Siding manufacturers offer a full set of panels and elements with which you can sheathe a house, even with a complex configuration. The buyer, as a rule, indicates only the area of the walls of the house, their dimensions, the type of roof, as well as the number of windows. The information obtained allows the seller to calculate the required number of required elements.

What are the components required to install the siding?

- Outside corner. It is used both for decorative purposes and to close the ends of siding.

- Internal corner. They are used where the siding joins the wall.

- Wind board and spotlights. They are installed when finishing the cornice.

- Starting bar. Its length is calculated based on the perimeter of the house minus the width of the doors and gables.

- L-profile. It is necessary in areas where there is a drop in roofs or heights, as well as where extensions are connected.

- Window strip. The perimeter of the windows is sheathed with it.

- Ebb. They are also used to frame windows.

- Ebb or drain bar. These elements are installed around the perimeter of the base.

- The siding panels themselves.

- Galvanized self-tapping screws (25-35 mm) or nails, which will be used for installation.

Preparatory work

What needs to be done in order to do the installation of siding with your own hands? The step-by-step instruction introduces us to these steps and indicates that some preparation will be required directly on site. First of all, you need to dismantle all protruding elements of the building. These can be grilles and platbands, doors. Next, you need to close up all the cracks in the walls, around the windows, etc. To do this, you can take polyurethane foam or cement mortar... If the house is old, then its walls must be cleaned of dust and dirt, mold and paint, chipped plaster, as well as rotten areas. Wooden houses at the preparatory stage of installation, they are treated with antipyretics and antiseptics. Walls made of foam concrete are coated using a deep penetration primer.

Sheathing material

It should be borne in mind that the siding itself is not attached directly to the walls. That is why, at the first stage of installation, you will need to build a crate. This is a special frame on which the panels will be attached. Installation of siding without lathing is possible only if the walls of the house are wooden and at the same time they will be a perfectly flat and smooth surface. If the wall of the house is poorly leveled, which, as a rule, is the case, then you will need to build a crate from wooden slats or a metal profile. She will be the basis for the cladding panels.

How to install metal siding? The only option for this type of panel is a galvanized profile. It is also used for concrete and brick walls... As such a material, a CD profile designed for drywall can be used.

How to install vinyl siding? For this type of panels used for wood or frame house, it is necessary to prepare a crate of 60 x 40 mm slats, the residual moisture of which is in the range of 15-20%. Previously, they must not only be dried, but also treated with an antiseptic.

Arrangement of the frame

To install the lathing, you will need to draw straight lines on the walls of the house, thus obtaining a closed loop. To keep them horizontal and even, a level and tape measure are used. After that, from this line, they measure the distances in the corners of the house to the basement and, having found the smallest of them, draw a second contour. It is along the bottom line that the starting bar will pass in the future.

The next stage is the installation of the vertical components of the crate. This work must start from the corners. It should be borne in mind that the crate should fit snugly against the walls of the house, for which pieces of dense foam or wood are sometimes placed under it.

Warming and waterproofing

How to install siding? If the panels are installed on aerated concrete or wooden walls, then an obligatory stage of the work will be the arrangement of waterproofing. At the same time, the insulation can be laid at the request of the owner.

The most popular waterproofing material in Lately is a moisture-proof membrane. If the walls are not insulated, then the film will need to be fixed directly on the facade of the house. This will save the space that the siding needs to ventilate. If an insulating layer is installed, then waterproofing should be laid on top of it. After that, a crate is constructed to provide a ventilation gap.

Installation of J-profiles

How do I attach the starting siding bar? This guide piece must be perfectly level. The quality of the entire facing surface will depend on its correct horizontal position in the future. How to correctly install this strip? To do this, you should use the step-by-step instructions:

- Take the level and find the bottom point on the crate. After that, stepping back 50 mm upwards from it, put a mark, which will serve as a self-tapping screw slightly screwed into the rail.

- Move consistently around the building and continue putting down the marks necessary to fix the starting bars. In addition, self-tapping screws must be screwed in at the corners of the house.

- Moving further along the line, leave a 6 mm horizontal gap from the intended edge of the corner profiles.

After carrying out all these works, the starting guide for the siding panels is fixed to the frame rails with screws or nails.

Weir installation

How to install siding? House paneling work should begin with the installation of a spillway. It is necessary to protect the base. The upper edge of the spillway, which is a hinged bar, should be located along the previously outlined bottom line on the facade of the house. This design is quite rigid. That is why its installation will not be difficult.

Installation of corner profiles

How to install vinyl siding? After completing the lathing and installing the weir above the plinth, it is the turn of the corner profiles. They are rigidly fixed along a strictly vertical line. If you follow the instructions for installing the siding, then the upper edge of the corner profile will need to be located 5-6 mm from the eaves. The lower one, on the contrary, should be lowered by 7-8 mm from the installed starting bar. Installation of siding corners, if one lanka is not enough, overlap.

The fasteners should be made in such a way that the upper part flows over the lower one. The corner profile is fixed with nails or self-tapping screws at intervals of 20-40 centimeters.

Framing openings

For most inexperienced craftsmen, this stage of work seems to be the most difficult. However, to complete it, it is enough to carefully study the instructions for installing siding.

J-profiles or window strips must be fixed in such a way that their outer bottom edge is slightly lower than the inner one. When framing the doors, the corners of the elements are filed at an angle of 45 degrees or overlapped when overlapping the upper strips on the side ones.

Fastening siding

After carrying out all the above work, you can proceed to the direct sheathing of the house with panels. It should be borne in mind that vinyl siding should be mounted only in the special holes it has. It is not recommended to punch the panel with nails and screws. Otherwise, the service life of the product will be significantly reduced.

Attach the siding to a wooden crate. Its first row must be attached to the starter bar. From below, you need to wait for the lock to click, and from above, attach the panel with self-tapping screws. All other rows are installed according to the same principle. After installing the last panel, a finishing strip must be attached to the crate.

Some owners, in order to give their home a more attractive look, decide to install basement siding on its facade.

How do you mount these panels? Such works are similar to those described above for building facades. The fasteners for siding are the same - nails or screws.

Today, vinyl siding is increasingly used for cladding low-rise buildings, balconies, and various structures. Even a beginner knows how to attach vinyl siding to a house, the main difficulties are caused precisely preparatory stage: execution of the frame and installation of all necessary components.

House cladding with siding is beautiful, practical and warm.

Consider the various stages of work: fastening the material to the profile, finishing the corners, sheathing the cornice, including the installation of vinyl siding with your own hands.

What tools are needed to work with siding

For vinyl siding installation and execution preparatory work you will need the following tools:

- Bulgarian with several types of circles. It will be used to cut panels. When joining siding at corners or at the joints, it is necessary to achieve perfect cut flatness.

- Hacksaw for metal. It is used for trimming small elements or correcting defects when working with a grinder.

- Screwdriver with various attachments.

- To install the lathing on the facade of the building, you must have a perforator.

Tools for working with corrugated board: grinder, hacksaw for metal, screwdriver, perforator.

For fasteners, you need to stock up on the required number of nails, self-tapping screws, press washers with wide heads. The diameter of these caps should not be less than 0.9 mm. If you use hats with a smaller diameter, then this threatens the release of the fasteners inside the siding.

Professionals advise using press washers in fastening, they do not corrode and perfectly fix the siding on any frame.

A tape measure, a construction knife and a level are useful in work. Do not neglect protective clothing and goggles. Very often, when cutting vinyl siding, small particles of material fall into the eyes.

Several useful tips before working with vinyl siding:

- Before you start installing vinyl siding, it is worth knowing that this material has a high expansion rate. Therefore, a gap of at least 7 mm must remain between the starter planks and the rows of siding. If you decide to install vinyl siding at temperatures below freezing, then this gap should be more than 1 cm.

- There should also be a gap between the work surface and the fasteners themselves.

- You should not immediately start working as soon as the material has got to your yard. He needs to lie down in the open air for at least 3 hours.

- It is forbidden to mount the siding through and through with self-tapping screws. This will shorten the life of this material, and it will simply crack.

Preparatory work

- Installation of the lathing.

This stage of work is mandatory regardless of the material from which the walls are made. This is due to the need to leave a gap for the air cushion, which helps prevent mold and mildew on the walls. You will also be able to create the correct plane for fastening, since the walls of the house are rarely perfectly flat.

If you have a house with wooden walls, then the best option would be a frame made of wooden bars. But it is worth remembering that only well-dried bars are suitable for installation. This is to avoid further spillage.

It is better to impregnate the assembled frame with a refractory liquid to avoid possible fire. The same can be done with wooden walls.

If you do the installation of siding with your own hands, then it is better to install the bars of the lattice vertically. The distance between the guides should be 30-40 cm.

Professionals advise you to additionally insulate your house, perform a horizontal crate, which will allow you to lay insulation plates.

Another option for the lathing will be a metal profile structure. It is easier and faster to work with it. It can be mounted using special hangers, they make it possible to maintain the required indentation from the wall.

You can also use dowels for installation, which are installed in pre-drilled points. If the walls of the house are built of aerated concrete, then it is necessary to use special fasteners for installing heavy metal siding - chemical anchors.

It is necessary to assemble the crate from the extreme guides in the corners of the house. Then, using a level and a cord, intermediate guides are set and aligned.

When the outer guides are exposed, they should not be attached end-to-end to the corner of the building. In the future, a profile will be mounted to them, and some space should remain for it.

- Installation of insulation and vapor barrier.

If the thermal insulation technology is performed correctly, the heat will be retained longer up to 2 times.

If you decide to give the house good view, then it does not hurt to think about additional insulation. Vinyl siding does not function as insulation, so you can use the space between the house and the siding just for insulation.

First you need to fix vapor barrier film, then heat-insulating plates are laid, and from above it is closed with a membrane. The last layer is very important, as it allows air to escape freely and protects the house from wind penetration.

Vinyl siding trim

- Fastening the starting strip.

Siding installation begins with the use of a starter bar. It is fixed around the entire perimeter of the house. There are no special requirements for fixing this strip, it will be completely covered by a number of panels. Here you can also use pieces by connecting them together. But it is worth taking with all the responsibility to align it to the level. It is the starting strip that will set the tone for all the work, it will depend on how quickly you get the job done, and how long you will adjust the siding to each other.

- Fastening vinyl siding to the wall.

Correct installation of siding is the key to a long service life.

Here you should follow these rules:

- self-tapping screws must be fastened at a distance of 300 mm from each other;

- hammering nails, screwing in self-tapping screws must be strictly perpendicular to the surface;

- it is necessary to install the self-tapping screw clearly in the middle of the nail hole, this will allow the material to move freely with further expansion;

- it is not necessary to tighten the screws all the way to the stop, it is better to leave a small gap of up to 1 mm;

- do not install the planks to the very corner. Special strips are provided for the outer corner.

- How to sew an obtuse and acute corner correctly?

Knowing that vinyl siding corner strips are very flexible, they can be used for both blunt and sharp corners. When installing them, you need to remember the required expansion gap.

- Installation technology for ordinary panels.

Installing ordinary panels is not difficult. They can be fixed in a circle or finished along one wall. There is not much difference here.

First, the first strip is installed, which is fixed in the vertical grooves of the H-shaped profile and fixed with a self-tapping screw. All other siding panels are attached in parallel, fixed with special locks, and in the middle with self-tapping screws. It is worth remembering the necessary clearance for further expansion.

- Installation of finishing planks and the last row of siding.

The work takes place in this way: the finishing bar is attached, with the help of a tape measure the distance from the last row to it is measured. This will be the width of the last siding plank. Using a grinder, the siding is adjusted to the desired size. Bending the strip horizontally, it is wound up under the finish bar.

DIY vinyl siding installation: final moments

Installation of siding frotons is in progress.

Roof gable diagram

The principle of operation is similar to the cladding of an entire house. First, the starter strip is attached, then the J-profile for the roof slopes is installed and the siding strips are fixed. When performing all these works, it is worth remembering the required clearance.

If your wall is longer than the length of the siding strip, then a connector strip must be used. As practice shows, its location must be thought out in advance so that it does not turn out that it will pass in the middle of a window or doorway. It is also important to calculate its location in order to avoid large pieces of scrap that would be unnecessary.

Installation of vinyl siding does not cause any particular difficulties, if you carefully read all the stages of work, prepare required material and take responsibility for all types of work.