Plant waste in the form of branches and grass are inevitable companions of the garden plot. Burning or patiently waiting for the waste to turn into compost is impractical. It is much more efficient to assemble a garden shredder with your own hands. The resulting raw material is useful as fuel for the boiler or soil fertilizer. After familiarizing yourself with the principle of operation and types of waste recycling mechanism, choose a suitable design for self-manufacturing It will be easier.

The device and principle of operation of the garden shredder

Garden shredders make gardening a lot easier. When describing the mechanism, in addition to the usual name, there are also synonyms - a chipper or a shredder. They have a fairly simple design. The main components of the mechanism:

- working shaft equipped with knives;

- motor;

- receiving box;

- metal frame with protective cover;

- in some models, a hopper for crushed organics is provided;

- a sieve that regulates the fraction of chips;

- pusher.

In addition to the main elements, there are many other small details. For convenient movement, the entire structure is based on a two-wheeled basis. The working principle of the garden shredder is as follows:

- The chain or belt serves as a transmission link for the movement of the shaft due to the rotation of the motor.

- At this point, branches or other waste are fed into the receiving box.

- The knives of the working shaft crush the introduced plant material.

The resulting raw material can be composted. The work of a garden chopper is akin to the action of a meat grinder.

Comment! Recycling of waste, especially solid waste, is carried out with precautions. Leather gloves and goggles are mandatory personal protective equipment.

Types of shredders

Before you create a homemade garden shredder, you need to decide on the type of waste to be loaded. This depends on its design and performance. The classification of garden shredders is carried out according to three parameters: the type of drive, its power, the type of cutting structure.

cutting mechanism

Factory-made shredders have the following cutting systems:

- Knife (Fig. 4). They represent a universal option.

- Milling (Fig. 2). Process solid plant organic matter.

- Rotating turbines for recycling thick branches (Fig. 3).

- Valkov. Designed for bushes and tree branches.

- Molotkovy (Fig. 1). Able to grind thin branches.

- The grass chopper is equipped with a fishing line instead of knives.

There are other designs of shredders on the market. If you want to assemble an electric garden shredder with your own hands, they stop at models with a knife cutting system or consisting of typesetting circular saws.

type of drive

The garden wood shredder is equipped with a gasoline or electric motor, each option has advantages and disadvantages. A gasoline-powered chipper can handle large branches more easily. It is characterized by mobility and independence from the remoteness of the power source. But some designs need to be connected to agricultural machinery in the form of a walk-behind tractor or a tractor.

The electric garden wood shredder is lighter, less bulky and easier to operate. Disadvantages - binding to an energy resource and less power. Depending on the planned size of organics intended for processing, the following engines are selected:

- With low intensity of work with branches up to 20 mm in diameter, a power of 1.5 kW is sufficient.

- A small area where you need to process branches up to 40 mm thick is best equipped with a 3-4 kW chopper.

- For large farms, where it is often necessary to dispose of branches up to 100-150 mm thick, it is better to make a shredder with a 6 kW engine.

Advice! With versatile garden work it is preferable to make a shredder with a 4 kW motor. For gasoline models, an internal combustion engine is suitable, the power of which is 5-6 hp.

Another design feature of garden shredders is the type of drive. This function is performed by a belt, a chain or fixation of knives is carried out directly to the motor shaft.

Materials and drawings to create your own chipper

For self-production of a garden shredder, where circular saws are used as a cutting mechanism, you will need:

- Electric motor up to 2 kW.

- Cutter with large teeth, or 10-15 pcs. circular saws Ø 10-20 cm.

- Axle with a suitable diameter for circular saws.

- Separation of disks in the garden shredder is carried out by washers 5-7 mm thick. Their inner hole is selected depending on the diameter of the axle, and the number corresponds to a set of discs.

- The drive function is performed by a belt with pulleys.

- A corner is being prepared for the bed.

- Steel sheets for the receiving box and the guide socket 5 and 3 mm, respectively.

- Two wheels for mobility of the garden shredder.

- Drill, grinder, welding machine and a set of fasteners.

There are many designs of garden shredders, for example, a grass chopper differs from a branch disposal device. We offer a choice of drawings of garden shredders:

Molotkovy

For circular saws

For grass

How to make a wood chipper

Consider step by step how to make a garden shredder with your own hands:

- A set of circular saws and washers is alternately mounted on the shaft. It is machined on a lathe or a part is used from the gearbox of an old car.

- The gap between the discs is about 10 mm. With a smaller gap, the width of the working area will narrow, a larger gap will provoke jamming of small branches.

Attention! Circular saws are fixed in such a way that the teeth are not located on the same line. They are installed with an offset or randomly. With this fastening, the load on the shaft and the electric motor is reduced, increasing the resource of the garden shredder.

- A corner or channel serves as the basis for a solid frame.

- Under the place of installation of the electric motor, a foundation is equipped. The support must provide for the movement of the motor in order to adjust the drive tension.

- Next, pedestals for bearings are formed, here it is important to prevent distortions. The axis of the shaft and the electric motor must be in parallel planes.

- The next step in creating a garden shredder is the formation of a working hopper. The container must have sufficient strength to withstand the mechanical impact of the flying parts of the branches. Close attention deserves the base plate, which rests against the crushing of wood.

- If the made hopper has the ability to adjust relative to the cutting parts, the size of the chopped chips may vary. For example, larger fragments are needed as fuel, smaller fragments are needed for compost.

To supply branches, it is required to make a bell, the depth of which exceeds the length of the arms. It performs two functions:

- allows you to guide the wood into the garden shredder at an optimally comfortable angle of 90 °;

- effectively protect hands from damage.

Guide wood waste to the place of grinding should be a special board, you should not do it yourself.

Advice! Branches of fruit trees are processed in the garden shredder separately from the rest of the wood waste. The resulting wood chips are ideal fuel for a smokehouse. Also, do not mix wood intended as a material for smoking with stone fruit and pome trees.

grass grinder

If work on garden plot does not involve the disposal of thick branches, and the main waste is soft vegetation, you should consider how to create a grass chopper. Instead of powerful saw teeth, a cutting system similar to a cabbage shredder is equipped. The principle of operation of the mechanism is shown in the drawing below:

The rotation of the disc cutter at high speeds allows you to cut pieces from grass or thin branches. The high performance of the shredder ensures a fast processing of unwanted vegetation. For work you will need:

- A round container in the form of a bucket or pan will cope with the role of a working hopper for a garden grass chopper. The absence of thick branches does not require the special strength of the walls of the garden shredder.

- Spare parts from the old ventilation system, called a snail, are perfect for assembling a garden shredder. The electric motor, shaft and fan housing are the main components that can be borrowed for your own design.

- A metal disc is used as a cutting system, in special slots of which knives are fixed.

Falling into the slots, the soft vegetation is crushed and goes out into the side hole. For this design, it is important to equip the feed bell so that the limbs cannot come into contact with the cutter.

A garden grass chopper does not need a powerful electric motor, there is enough power of 1 kW, even a grinder is suitable for these purposes. Details of arranging a garden grass shredder can be seen in the following video:

The cost of garden shredders that you can buy in stores is quite high, especially when it comes to popular models of certain brands.

Therefore, some people try to make such devices on their own.

In this article, we will talk about different models home-made garden shredders of branches for a summer residence and we will give step by step guide for the manufacture of such devices.

All homemade products are possible conditionally divided into 3 types:

- wood chips;

- mulchers;

- shredders.

chip cutters are designed for chopping branches and completely dried large green mass, that is, thick stems.

chip cutters are designed for chopping branches and completely dried large green mass, that is, thick stems.

They are poorly suited for processing and grinding fresh or slightly dried green mass, that is:

- leaves;

- herbs;

- tops.

More often chipper made in the form of a rotary chipper. We talked about how this device works, its principle of operation, and how to make it yourself, and showed it on video in these articles:

A home-made apparatus of this type effectively grinds branches of a certain thickness, turning them into small wood chips that can be used as:

- and agrotechnical garden plot;

- dye and flavoring at;

- fuel with various products;

- bedding for animals and birds;

- and ovens.

mulcher it is intended for crushing fresh and dried green mass, but is not suitable for processing dry tops and any branches. Its basis is the fishing line cutting module, which we talked about.

Chopped green mass can be use only as a decorative or agrotechnical mulch, hence the name of the device.

The shredder is designed for rough chopping of branches, so the finished wood chips are used only for heating.

In industrial shredders, it is possible to produce chips of a normal size, but in home-made devices, simplicity of design and ease of manufacture are considered the most important quality, which becomes the reason for increasing the size of the chips.

Choice of engine type: electric or petrol?

When choosing an engine for a homemade chopper you need take into account the availability of components.

If the garage has a good gasoline engine of suitable power (2-5 hp), then it can be installed on most DIY garden shredders.

benzie new engine make the grinding plant autonomous, so it can be used even where there is no way to connect to a power outlet.

If the device will work only near the outlet, then it is better opt for an electric motor. Even if you have to buy the difference in operating costs quickly compensates your expenses.

The cost of an hour of operation of a garden electric shredder is 7-10 times less than a device that has a two-stroke gasoline engine, or 10-12 times less than a device with a four-stroke gasoline engine.

This related how with the difference in the cost of electricity and gasoline, and in the cost of servicing gasoline engines.

Another factor, which affects the choice of engine - ease of installation. Gasoline engines work well only when their shaft is horizontal.

Therefore, to connect to the vertical shaft of the chopper, and this is how the mulcher shaft is installed, you will need a gearbox that provides a rotation of 90 degrees. That is, you have to spend not only on the engine, but also on the gearbox. And the electric motor works well in any arrangement of the shaft, so you can do without a gearbox.

Drafting

In order not to have to redo a partially assembled garden apparatus, it is necessary to correctly draw up a drawing, taking into account the dimensions and shape of all available parts.

This will help numerous forums where users discuss the most successful configurations and technical solutions.

This will help numerous forums where users discuss the most successful configurations and technical solutions.

In addition, they also share their experience in making garden waste and garbage shredders on their own, posting not only drawings, but also photos from videos of their devices, and also leave feedback on their work.

When drawing up schemes you you will be able to determine the location of mounting holes and welds. This will allow you to first make individual parts with advance drilled holes, and then, without fitting, attach the appropriate units to them.

Ready-made drawings can be found on the Internet, after which, on their basis, make a new drawing with dimensions yourself, in which there will be features of available parts and mechanisms are taken into account.

The main advantage of this method is that it eliminates the need to independently determine and calculate the overall configuration of the finished device and the location of the main elements.

Here are drawings of some devices that can be used as bases:

- Drawing 1 - This standard design stationary rotary chipper that works well as a garden shredder.

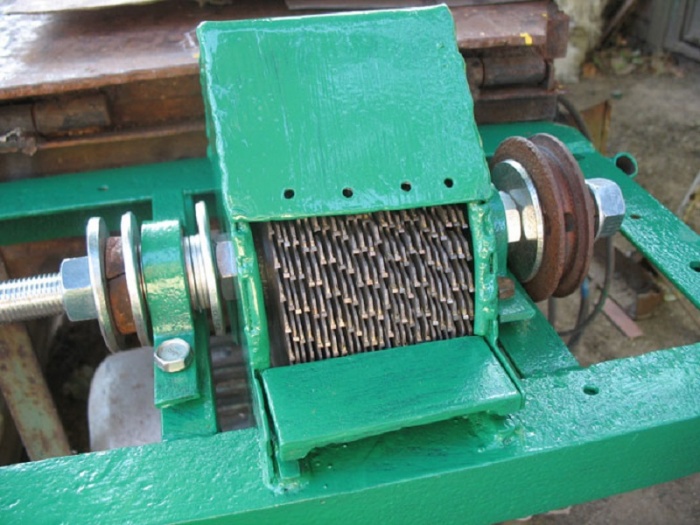

- Drawing 2 - This is the design of one of the shafts of a two-roll shredder. With some modifications, it can also be used in single shaft shredders.

- Drawing 3 - The device of a two-roll shredder.

- Drawing 4 - Drawing of a grass chopper with an electric motor, however, instead of an electric motor, you can install a grinder or a drill.

Thematic forums

To make a properly functioning garden shredder of any type, it is necessary not only to understand general principles his work and the requirements placed on him, but also get to know the experience those who have already experienced this kind of work.

There are many forums on the Internet where users discuss their own homemade products and share their experience of using them, so you can learn a lot of important information there.

Self-manufacturing

In this section we present a step by step guide to independent production of shredder and mulcher, a detailed instructions you can find about creating a wood chipper.

The method of making a mulcher depends on the available components.

It can be made from a grinder by installing a fishing line instead of a disk, or from an ordinary induction motor with a shaft rotation speed of 1.5–3 thousand rpm.

In the first case, it is necessary to place the angle grinder with a fishing line in some pipe or container, which limit the spread of chopped grass, and in the second - you can make a full-fledged chopper.

mulcher

For making a homemade garden electric mulcher for processing thin branches and grass will be required:

For making a homemade garden electric mulcher for processing thin branches and grass will be required:

- asynchronous motor alternating current with a power of 1.5 or more kW with a mounting platform (sole) perpendicular to the shaft;

- steel pipe with an inner diameter of 30–50 cm;

- steel corner with a shelf size of 15–30 mm;

- steel bar with a diameter of 8–15 mm.

You will also need a steel plate for mounting the electric motor, an adapter for attaching the drum to the shaft and a drum for fishing line.

If there is no drum for fishing line or a mulcher will be used to process tough haulm, then instead of the drum, you can install 1-3 steel strips, placing them at equal angles. It is desirable to sharpen the edges of the strips, this will improve performance and reduce the load on the engine.

The main thing is that the hole for attaching to the shaft is exactly in the middle, otherwise there will be a strong vibration, which will lead to the appearance of a hum and a sharp decrease in the life of the bearings.

Here procedure to be followed to make a mulcher:

- The pipe is cut both sides at a 90 degree angle. The length of the cut section should be 40–60 cm. The plate for mounting the engine is cut to the size of the sole, holes are drilled in the necessary places (under the shaft and mounting bolts), after which the engine is fixed for verification.

- If everything is normal, then the engine is removed and 3 corners are welded to the bottom of the plate located relative to each other at an angle of 120 degrees.

- per plate install the engine, fix with bolts and attach the drum to it. If there is no drum, then instead of it put steel strips or metal knives from any trimmer. It may be necessary to install an adapter that compensates for the difference in the diameter of the shaft or extension and the diameter of the knife hole.

- plate with welded corners installed on the top edge of the pipe, positioning so that the motor shaft is as close as possible to the center of the pipe, then weld the corners to the pipe and cut off the excess.

- Bolted connection can be used instead of welding, this will complicate the installation, but greatly facilitate the maintenance of the device. To do this, each corner is cut close to the wall, then the “heel”, that is, a small steel plate with a bolt hole, is welded to reverse side which the nut is welded on. Then holes are drilled in the pipe body and the engine mount is bolted.

- You can also cut the body (pipe) into 2 parts at the level of the edge of the shaft, then weld mounting plates with nuts to any of the parts, and drill holes in the corresponding places of the other part of the pipe.

- From steel rod make a grid with a cell size of 3–5 cm. If the body is made non-separable, and the motor suspension is fixed by welding, then the mesh is bolted so that it can be removed for cleaning and replacing the fishing line. In an installation with a demountable body or a removable engine mount, the mesh can be fixed by welding. Sometimes, instead of a grid, a solid bottom is made, in which a round hole is cut, which plays the role of a sieve.

- Legs from the corner are welded to the bottom of the body, deflecting them outward by 20–40 degrees. The length of the legs should be sufficient so that a bucket can be placed under the mulcher. It is desirable to weld a “heel” to the bottom of each leg - that is, a piece of steel plate measuring 5x5 cm. The length of each leg, as well as the angle of deviation, must be the same so that the whole structure is stable.

- Before each start, open access to the drum and check the condition of the fishing line, if necessary, change it. If knives are installed instead of fishing line, then their condition and sharpening are checked in order to replace or sharpen if necessary.

shredder

Although the design of a shredder is much simpler than many other wood shredders, it is quite difficult to make one yourself due to the very high overall cost of parts that must be made to order using certain grades of steel.

Therefore, in everyday life more popular simplified shredder model With homemade knives from automobile springs and steel corners.

For the manufacture of such a homemade electric garden shredder will be required:

- sheet steel 20 mm thick;

- sheet steel 2 mm thick;

- steel gears the same size and pitch with an outer diameter of 8 or more cm;

- asynchronous electric motor with a power of 3 or more kW;

- powerful gearbox with a gear ratio of 50–100 (the larger the gear ratio, the lower the speed of rotation of the shafts, but the higher the torque);

- steel corner with a shelf size of 50 mm;

- spring from a car;

- a flat steel bar with a diameter of 40–50 mm (you can use one of the gearbox shafts or a shaft from some other equipment if it fits in diameter);

- bearings.

Here procedure:

Here procedure:

- 2 pieces are cut from a steel bar, one 35–40 cm long, the second 40–45 cm long.

- Cut 4 pieces of a corner 25–30 cm long.

- Weld on 2 corners for each rod, to get a square shaft.

- From thin sheet steel cut out 4 circles, the outer diameter of which is equal to the outer diameter of the bearings, and the inner diameter is equal to the outer diameter of the shaft.

- Circles put on shafts and welded to corners.

- 8 pieces are cut from the spring, the length of which is 2 cm less than the length of the shaft, after which one of the long sides is sharpened at an angle of 30–40 degrees. The smaller the angle, the better knife will cut wood, but it will also become dull faster.

- 3-4 mounting holes are drilled in each knife, then drill holes matched with them in the corners of the shafts (the diameter of these holes should be slightly smaller so that they can be threaded). In this case, each knife should protrude so that the knives of both shafts come into contact with each other when they meet. Threads are cut in the finished shaft holes.

- From thick steel sheet cut body parts. Its size can be any, the main thing is that the width is equal to the distance between the bearings on the shaft, and the height is not less than the distance between the far knives of both shafts. In total, 8 parts are needed - 2 side walls, upper and lower walls, 4 amplifiers.

- In the side walls cut holes for bearings. This is a very responsible operation, so even a 1 mm error will lead to serious problems.

- The side parts are welded to the bottom, then the amplifiers are welded - 2 pieces from the top from the front and back sides, 2 pieces from the bottom also from the front and back sides.

- Choose the method of fastening the gear to the shaft- most often, welding or keying is used for this (this option is only suitable for processing thin branches, an attempt to chop thick branches can lead to a break in the key).

- Connect Lead(longer) shaft with gear. To do this, you can use a chain or gear transmission, as well as an adapter made of thick-walled steel pipe.

- Attach an electric motor to the gearbox.

- If the case turned out to be unstable, then from below weld 4 legs, set aside at an angle of 25–35 degrees and equip them with heels measuring 5x5 or 10x10 cm.

Choppers from a grinder and other tools

As a basis to create a garden shredder can be used:

- grinder;

- drill;

- trimmer.

Bulgarian, due to the high engine power and high speed, it can chop thin branches and grass, however, for this it must be firmly attached to a vertical surface and an inlet must be made in this surface.

For chopping grass, you can use a three-blade knife from a trimmer, and for processing branches, the knife will need to be made from tool steel to order. You can make a knife from tough steel, and replaceable blades from the most durable.

Drill used in the same way as the mulcher engine, fixing in any way. Due to the low speed of rotation of the cartridge, it is pointless to install a drum, so a shaft is made to which knives are welded or otherwise attached.

Trimmer also used in conjunction with the mulcher body, fixed so that the drum with fishing line is parallel to the surface of the sieve.

Related videos

This video shows a homemade branch chopper in the process:

Conclusion

The main advantage of a homemade device is that it is many times cheaper than a store bought one. In addition, by making your own garden shredder, you can optimize it for processing certain materials.

Now you know:

- what are homemade devices;

- what is needed for their manufacture;

- how to make them by hand.

In contact with

The branch shredder is one of the necessary tools gardener. After all, everyone who cares for the territory has to regularly cut trees, resulting in waste. It is problematic to burn such garbage in the oven without first crushing it with an ax, and making a huge fire in the garden is also impractical. The solution could be an electric garden shredder. After being crushed, the branches turn into solid fuel or compost.

Currently, wood shredders are called differently: wood chipper, wood chipper, shredder, wood chipper, wood chipper, knot crusher, device for processing plastic, paper and sawdust, etc. The device consists of the following units:

As for homemade choppers, they differ only in the design of the cutting mechanism, and the rest of the details in them may have different sizes. If you are planning to make a wood chipper with your own hands, drawings and diagrams will be the first thing you need. They can be found on the Internet. Here are the most popular solutions:

To improve the performance of the grinder, a flywheel is often installed that fits on the free end of the shaft. In disk models, this part is replaced by a heavy metal circle with knives.

A wood chipper is a very handy tool. However, not everyone can afford such a purchase, so most gardeners prefer homemade solutions. But is it possible to create a device without the appropriate metalwork and welding skills and tools? Unfortunately no. Even a simple wood chipper based on circular saws is created subject to strict instructions. In addition, for the creation of shafts and housings for bearings, you need to turn to professional craftsmen. The whole process can be divided into the following steps:

When creating, you should be guided by the following rules:

- If the priority is to obtain small wood chips with minimal resources, give preference to models from circular saws.

- If you are going to grind small diameter branches into a larger fraction, a cutting mechanism, such as a jointer, will be the ideal solution.

- If you want to cut branches in large quantities, equip disc crushers.

By the way, small chips and wood chips are often used to make compost and mulch. In addition, fuel briquettes are created on its basis, which are then used to heat private houses.

By the way, small chips and wood chips are often used to make compost and mulch. In addition, fuel briquettes are created on its basis, which are then used to heat private houses.

If you have decided with choice of chippers, start harvesting parts, materials and equipment. Before that, however, there are a few key tasks that need to be completed.

Engine selection and belt drive definition

An indicator such as drive power indicates the thickness of the branches that a home-made device can process:

However, the number of revolutions of the electric motor practically does not play a role, since the required speed of rotation of the cutting elements is provided by a V-belt drive.

However, the number of revolutions of the electric motor practically does not play a role, since the required speed of rotation of the cutting elements is provided by a V-belt drive.

To wood shredder coped with his duties with a bang, the knife shaft should operate at a speed of no more than 1500 rpm. Such indicators can be achieved by choosing the appropriate diameter of the driving and driven pulleys. It is not the speed of the blades that is decisive, but the resulting torque or force. . It also makes no sense to give special attention to the distance between the pulleys and the length of the belt, with the exception of too long belts, which significantly reduce the efficiency of the transmission.

As an example, we can choose the following calculation: we take an electric motor at 2800 rpm, which will be installed on the crusher. The ideal solution there will be a reduction in the speed on the shaft by half, to 1400 rpm. In this case, the pulley diameters will be two times different. For example, the size of the driving pulley is 100 millimeters, and the diameter of the driven pulley reaches 200 mm.

When ordering pulleys for V-belt transmission in a lathe, please note: it is better to give preference to pulleys for 3 or 4 streams, so that after that you can change the speed on the working shaft by shifting the belt. In this case, it will be possible to adjust chopper under different conditions work, for example, for processing corn stalks, sunflowers or grass.

Preparation of materials

To assemble the chopper frame, the following types of rolled metal are used:

The power plant is fixed on a steel sheet 10 millimeters thick (dimensions are determined by the distance between the mounting holes). The following options are used as a belt tensioner:

- The holes in the plate for mounting the motor are made oblong, which allows you to push it back and fix it with bolts.

- The plate is mounted with one end on a hinge, as a result of which the belt is pulled up by the weight of the electric motor. On the other side, it is fixed with stud nuts.

For creating the simplest design

shredder, you need to purchase 20-25 carbide-tipped saw blades and a similar number of spacer washers with a diameter of 20 millimeters. As a result, a working part is created with a width of about 80 millimeters, which can be increased by adding saws.

For creating the simplest design

shredder, you need to purchase 20-25 carbide-tipped saw blades and a similar number of spacer washers with a diameter of 20 millimeters. As a result, a working part is created with a width of about 80 millimeters, which can be increased by adding saws.

The thickness of the teeth of a circular saw is greater than the steel base, so it is forbidden to fix the tools close to each other. To compensate for the width of the teeth, it is customary to use washers that are placed between the saws.

The shaft, driven by a belt, is turned on a lathe from a steel rod. However, before manufacturing the part, 2 bearings should be made, under whose seat size the shaft will be machined.

In addition, bearing housings with mounting flanges should be equipped. Often they are bought ready-made in the secondary market or in specialized stores.

A good alternative can be rear axle bearings with a diameter of 25 mm - from the classic Zhiguli. In this case, the role of the shaft will be performed by a finished stud with nuts.

To fix the circular saws on the shaft, threads are cut.

Frame manufacturing features

Regardless of the type of crushing equipment chosen, it must be equipped with a key element - a bed, where a drive and a chipping mechanism will soon be installed. It is customary to cook the device from corners or pipes, following the following step-by-step guide.

Remember to think about where you will install the electric motor. For homemade crushers, the best solution may be to install the motor in the frame alignment so that it does not stick out beyond its dimensions. A similar rule applies to other types of crushers.

Chopper assembly

To assemble a wood chipper from a package of circular saws, follow the instructions:

Lubricate the bearing cages immediately prior to assembly. Install the saw blades so that the tooth profiles do not match.

Lubricate the bearing cages immediately prior to assembly. Install the saw blades so that the tooth profiles do not match.

To fix the counter knife, it is better to use bolts rather than welding, threading them through oval-shaped holes.

let's consider different kinds and designs of garden shredders for twigs, wood chips, grass and grain, capable of handling any type of vegetable waste. For you, we have collected a selection of drawings and instructions for making a do-it-yourself knife garden shredder.

There are always a lot of cut branches, grass, tops and other plant waste in the garden. You can collect them and burn them, you can put them in a huge pile in the hope that someday you will get compost, or you can prepare raw materials for quick production. organic fertilizer, for introducing wood chips into the soil in order to improve its structure, you can get an excellent mulch or fuel for the boiler. To do this, you need a garden shredder, which you can buy, or you can do it yourself.

Advice! Protect your hands and eyes when operating the shredder, especially if you are shredding solid waste. Glasses and leather gloves will protect you from injury.

Types of garden shredders, main components and elements

Shredders consist of a cutting mechanism, a drive, a loading hopper and a frame with a sheathing. In addition, they can be equipped with a hopper of crushed organic matter. Of the auxiliary means: a pusher and a sieve, which is used to obtain a certain fraction of wood chips. The residue on the sieve is sent for re-grinding.

Garden shredders are classified according to the type of cutting system and the type of drive.

Cutting systems

Commercially available chippers may have cutting systems:

- roll - branches and bushes;

- hammer - thin branches;

- milling - solid vegetable raw materials;

- with a rotating turbine - thick branches;

- knife - universal;

- trimmer (fishing line instead of knives) - grass, tops.

1 - hammer grinder; 2 - milling grinder; 3 - chopper with milling-turbine knives; 4 - knife disk chopper

1 - hammer grinder; 2 - milling grinder; 3 - chopper with milling-turbine knives; 4 - knife disk chopper

There are other designs as well. For self-production, knife and type-setting circular saws are suitable. The most common are knife blades, and the knives can be fixed on a massive disk in two, three or more pieces, or rotate towards each other in a two-roll design.

type of drive

Garden shredders can be powered by electricity or use two- and four-stroke gasoline engines. In practice, when making a do-it-yourself unit, they use an engine from a walk-behind tractor, which is idle for most of the year, or remove the motor from unnecessary household appliances. The main thing at the same time is that the power is sufficient - not lower than 1.1 kW. If there is nothing suitable, you can buy a new engine, but in this case, the benefits of a homemade chopper are no longer so tangible compared to a purchased product.

Some shredders that process exceptionally soft raw materials, such as succulent animal feed, may not be driven and run on human muscle effort. Below are drawings of shredders that you can do yourself.

Homemade hand choppers. A - two-knife chopper: 1 - knives; 2 - counter-cutting plates. B - multi-knife greens chopper: 1 - knives; 2 - counter-cutting plates; 3 - base frame. B - root crop grinder: 1 - shell; 2 - bearing; 3 - drum; 4 - cross; 5 - handle; 6 - end wall of the body; 7 - shield; 8 - pitched tray board; 9 - stand; 10 - side wall of the case

Homemade hand choppers. A - two-knife chopper: 1 - knives; 2 - counter-cutting plates. B - multi-knife greens chopper: 1 - knives; 2 - counter-cutting plates; 3 - base frame. B - root crop grinder: 1 - shell; 2 - bearing; 3 - drum; 4 - cross; 5 - handle; 6 - end wall of the body; 7 - shield; 8 - pitched tray board; 9 - stand; 10 - side wall of the case

In the first picture, the knives are made from old, one-sidedly sharpened saws; in the second, the knives and blades are made from saw blades. On the knives, oblique teeth are machined, like a saw, in 5 mm increments. Both shredders are equipped with long handles for lighter effort. The working part of the third structure is made in the form of a drum with notches, the sharp edges of which stick out.

Drawings of various designs of garden shredders

Consider several designs of shredders that you can assemble yourself.

Hammer grinder blueprint

Hammer grinder can crush branches, straw, corn stalks, grain.

1 - loading hopper (sheet δ1 mm); 2 - edging the neck of the loading hopper (corner 25x25); 3 - damper/valve (sheet δ1 mm); 4 - M6 bolt for screed (8 pcs.); 5 - framing the loading opening in the body (an equal-shelf corner 25 mm); 6 - hairpin M8 (8 pcs.); 7 - outer drum of the body (pipe Ø 270x6); 8 - stator with grooves (pipe Ø 258x6); 9 and 20 - hammers and spacers (sheet δ3 mm, hardened to hardness HRC 45-47, 72 pcs. and 70 pcs., respectively); 10 - latch Ø 3 (4 pcs.); 11 - M20 nut with spring washer; 12 - axis of the hammers (circle Ø 22, 4 pcs.); 13, 14 - piping piping (equal-shelf angle 25 mm); 15, 19 - gaskets (rubber, sheet δ3 mm); 16 - M8 nut for fastening the flange (8 pcs); 17 - hammer rotor; 18 — flange (sheet δ5 mm, 2 pieces); 21 - retainer; 22 - drive shaft

1 - loading hopper (sheet δ1 mm); 2 - edging the neck of the loading hopper (corner 25x25); 3 - damper/valve (sheet δ1 mm); 4 - M6 bolt for screed (8 pcs.); 5 - framing the loading opening in the body (an equal-shelf corner 25 mm); 6 - hairpin M8 (8 pcs.); 7 - outer drum of the body (pipe Ø 270x6); 8 - stator with grooves (pipe Ø 258x6); 9 and 20 - hammers and spacers (sheet δ3 mm, hardened to hardness HRC 45-47, 72 pcs. and 70 pcs., respectively); 10 - latch Ø 3 (4 pcs.); 11 - M20 nut with spring washer; 12 - axis of the hammers (circle Ø 22, 4 pcs.); 13, 14 - piping piping (equal-shelf angle 25 mm); 15, 19 - gaskets (rubber, sheet δ3 mm); 16 - M8 nut for fastening the flange (8 pcs); 17 - hammer rotor; 18 — flange (sheet δ5 mm, 2 pieces); 21 - retainer; 22 - drive shaft

Cutting Tool - Circular Saw Pack

A pack of 15-30 saw blades mounted on a shaft is one option for a shredder cutting system. Some craftsmen point out that the saw teeth quickly become clogged with plant matter. Others claim that they have achieved good work of the tool empirically - by setting teeth differently relative to neighboring saws. Since the carbide teeth are thicker than the blade itself, thin separators made of metal (for example, washers) or plastic must be installed between the saws, and the entire package is clamped with nuts.

Pack of 15 saws on the shaft

Pack of 15 saws on the shaft

As a drive, you can use a low-power walk-behind tractor, pulleys and bearings - used parts from a VAZ car. The bell of the loading hopper is a truncated pyramid, the outlet is small so that the human hand does not pass. It is better to make the frame for the chopper higher in order to remove the crushed raw materials less often.

Set of saw blades M20

Set of saw blades M20

Side view

Side view

Two-roll chopper

This chopper cuts branches into measured lengths from 2 to 8 cm, convenient for heating a sauna or wood-fired heating boiler. Its design consists of two shafts with knives - 3-4 pieces per shaft, rigidly fixed with bolts. Knives can be machined from a KamAZ or MAZ spring. If you can find a bulldozer knife, that's fine too. The shafts are fixed on massive sheets in parallel, at a distance sufficient for the knives to cut off the branch, but not to cling to each other. The free rotation of the shafts is provided by bearings, and their synchronization is achieved by a gear clutch moving with the help of a belt (chain) from the engine. To drive this grinder, it is advisable to use a high-power engine, but low speed.

If you want to create a mobile chopper, you need to provide wheel mounts on the frame.

frame element

frame element

Axle and shaft

Axle and shaft

Shaft Assembly

Shaft Assembly

The location of the shafts on the frame

The location of the shafts on the frame

Shafts from a square billet for 4 knives

Shafts from a square billet for 4 knives

The video shows a chopper with gears: driven gears - from the MTZ shank, fitted to right size, the drive (gear for transmitting torque to the shafts) was found by selection.

Making a garden shredder with your own hands

The most structurally simple and inexpensive chopper can be made from a disk with knives fixed on it, an engine, a frame and a hopper. The disk and knives can be turned on your own, ordered from a turner, or bought parts in a store. A cultivator engine is suitable as a drive, and it is not difficult to weld the frame and the hopper yourself.

Depending on how many knives are used and how they are set, the fraction of the resulting mulch may be different. The drawing below shows the basic design of such a grinder: a disk with four knives is installed vertically. Also, the design works well if the disk is fixed at an angle to the horizontal, and there are only 1 or 2 knives.

Assembly drawing: 1 - knives 4 pcs.; 2 - disk cutter; 3 - bearings No. 307

Assembly drawing: 1 - knives 4 pcs.; 2 - disk cutter; 3 - bearings No. 307

Operating procedure:

- Buy, order or grind your own disk with knives. The angle of sharpening knives is 35-45 degrees. The knife blade should have holes for bolts for attaching to the blade. It is important to correctly set the knives and secure them with bolts and stops.

- Weld the frame, taking into account the fasteners for the drive and other elements.

- Push the disc onto the drive shaft and secure.

- Weld the feeding hopper and, if necessary, the receiving hopper of the chopped mass.

- Collect all the elements on the frame.

If the frame is mounted on wheels, then the structure becomes mobile.

Disc turning

Disc turning

Knife set with fasteners

Knife set with fasteners

In the video, the master gives advice on the device of a homemade disc chopper.

A garden shredder is a mechanism designed for the processing of plant waste generated during grass mowing, sanitary or annual pruning of trees, grapes and various shrubs. The resulting small pieces of grass or branches can be used as livestock feed or fertilizer. The use of this unit allows gardeners, owners of summer cottages and lovers beautiful lawns dispose of organic waste faster and with less labor. The device is arranged relatively simply, for this reason it can be assembled by hand without any special financial costs from old parts and improvised materials. This allows you to save on the purchase of a finished factory device.

To independently assemble a grass and branch chopper (shredder) at home, you must first understand the device of the mechanism, as well as the principle of its operation. This will help to correctly assemble the equipment and, if necessary, make changes to its design.

A home-made unit designed for chopping mowed grass and cut branches up to several centimeters thick has the following main constructive nodes:

- engine;

- knives mounted on the working shaft;

- frame (usually metal);

- protective cover;

- a box designed to receive cut vegetation;

- starting system.

The technique itself can be done in a stationary or mobile form. To create the latter option, you will additionally need wheels, as well as a handle. To make a frame, use metal corners or ready-made frames from workbenches. Boxes for processed vegetation are made from plastic buckets, tin, bags. The protective cover around the blades must be thick and strong enough not to wear out quickly from the impact of the ground vegetation.

When processing plant debris, crushed pieces may fly out of the hole through which it is fed. Therefore, the neck is covered with a lid or simply with a cloth, for example, a bag.

The work of the chopper is that the rotation from the motor shaft is transmitted directly to the knives or through a chain / belt drive. Vegetation chopped with blades enters the box. In this case, the final product is immediately ready for use.

By operating principle some homemade shredders are comparable to a meat grinder (they draw in and then grind organic matter), while others are like a coffee grinder.

Varieties of engines for assembling homemade products

As a drive for homemade products use electric and petrol engines taken from unused equipment. Each of these two options has its advantages and disadvantages. Models with an internal combustion engine are more convenient because their operation does not require the presence of a power supply nearby. But in general, they are more expensive and have a more complex device than their counterparts equipped with an electric motor. Therefore, it is easier to make electrical equipment, in addition, more compact.

The maximum thickness of the cut branches that the wood shredder can grind depends on the power of the electric motor installed on it and the characteristics of the knives.

- Models with a motor up to 1.5 kW power are able to grind sticks up to 20 mm in diameter. They are designed for low intensity work.

- If an electric motor from 3 to 4 kW is installed, then such units can chop branches already up to 40 mm thick.

- More powerful electric motors (over 4 kW) are used to make a wood shredder with a diameter of 7-15 cm.

To create a homemade shredder, you can use electric motors from a grinder, washing machine, trimmer. They must be adapted to work from a stationary network with a voltage of 220 V. In order to shred material of the thickest possible thickness at home, it is recommended to equip the shredder with an electric motor at 1500 rpm with a power of about 3.5 kW. This parameter for internal combustion engines corresponds to 5-6 horsepower.

Engine from old washing machine

Types of used cutting nozzles

Homemade products, like factory units, are equipped with cutting nozzles of various types:

- disk (with three blades);

- milling;

- milling-turbine (universal).

The first variety is a flat blade. They grind plant debris during rotation. If you have to process branches, then such blades quickly become dull. Milling knives are a cutting shaft in the form of gears from circular saws. They grind dry waste from branches and grass well, and wet ones clog cutters. Milling-turbine cutting nozzles are able to cope with thick and not dried branches, but it is difficult to make them yourself.

At home, knives from lawn mowers or made from saws for wood are often used.

It should be borne in mind that the installed cutting nozzles directly depends the degree of processing of plant waste. At the output, pieces of branches from 10 cm long or shavings, dust are obtained.

Garden shredder from a washing machine

An old Soviet-made washing machine with a metal case is a technique that contains almost all the necessary parts for assembling a garden shredder. You only need knives with fasteners, as well as a wire for an extension cord.

To make a cutting nozzle, you can use an old wood saw.

Of the tools you will need:

- angle grinder;

- pliers;

- spanners;

- screwdriver;

- electric drill;

- hammer;

- tape measure with a marker.

Washing machine motor has low power different models different), indicated in the instructions for household appliances or on the nameplate of the electric motor. Due to the fact that usually its value does not exceed 500 watts, with the help of the created unit it will be possible to grind only straw or grass.

A shredder from a washing machine is made like this.

- Cut the body of the machine in height so that it is convenient to work with the unit.

- At the bottom side, a rectangular hole is cut out in it with a grinder 20 cm wide and 7 cm high, designed to throw out the ground plants.

- Around the slot, a kind of casing is made of tin, which will direct the grass mass into the collection container, while preventing it from scattering around.

- They make legs.

- Attach the body to the stand.

- 2 holes with a diameter of 7 mm are drilled on the motor shaft. Then a threaded sleeve is put on it, as well as holes at the end more than 5 cm long, fixing it with bolts.

- An electric motor is attached under the bottom of the box using studs with nuts.

- Inside the casing, knives are fixed on the sleeve, placing them above the grass ejection hole or at the same level with it.

- The box is attached by welding or bolts to the stand.

The result is a technique similar to the one shown in the photo below.

start button Suitable from a converted washing machine. You just need to take care to connect a sufficient length of extension cord.

The device and operation of a grass cutter from a modern washing machine are shown in the video

Homemade grass grinder from a grinder

A grass grinder from a grinder is a fairly simple and quickly implemented option. To implement the project, you will need to stock up on such details and materials:

- steel corners;

- metal container (ordinary digestion);

- homemade or ready-made knives (for example, from a lawn mower);

- fasteners;

- sheet metal.

From the tools you will need:

- electric drill;

- welding machine and electrodes to it;

- angle grinder to cut corners;

- spanners.

To assemble a shredder with your own hands on a corner base grinder, capable of grinding not only grass, but also branches up to 4 cm thick, it is recommended to use a power tool with a power of over 3 kW.

The creation of a grinding unit is carried out in the following sequence:

- grinder cut the corners into pieces;

- a frame resembling a chair is welded from them;

- weld a shelf from a piece of sheet metal;

- to the frame made (on the stand), the grinder is attached with clamps, placing it with a shaft to the top;

- cut a hole about 10 by 10 cm on the side of the boil;

- a sleeve is attached to the slot, for example, from tin, through which the ground plant mass will be issued from the container;

- make a hole in the center at the bottom of the boil;

- install the container on the shaft of the grinder and attach it with bolts or self-tapping screws to the metal frame;

- put a knife or disc on an angle grinder.

The result is a design shown in the photo below.

The dimensions of the corners are selected individually so that it is convenient to handle the mechanism.

It should be remembered that the frame must be stable. The safety of working with the device will depend on this.

A bucket or other container is placed under the pipe for issuing chopped grass with branches while working with the unit so that the processed plants do not scatter.

The created device can be improved. This will require grinder shaft attachment about 15 cm long with two knives: at the upper end and in the middle. The blades are separated by a mesh fixed to the casing wall.

Grass cutter from trimmer

A garden shredder can be made using a gas or electric trimmer. This will make the tool work. upside down. To create equipment designed to chop grass and thin twigs, you will need, in addition to brush cutters with cutting nozzles, the following materials:

- plastic or metal container having a volume of at least 50 liters;

- approximately 1 sq.m. steel mesh with fine mesh size;

- about 3 meters of metal tube (aluminum or steel) half an inch in diameter;

- a piece of board or moisture-resistant chipboard, plywood of such a width that a trimmer can fit on it;

- clamps with which the lawn mower will be attached to a wooden base;

- self-tapping screws, bolts, nuts, washers;

- wooden bars (enough 5 by 5 cm).

To assemble the grinding mechanism from the trimmer, you will need to use the following tools and fixtures:

- screwdriver or screwdriver with bits;

- an electric drill with a set of drills for wood and metal;

- an electric jigsaw with files for cutting metal or its manual counterpart;

- hammer;

- open-end or socket wrenches;

- punch;

- an anvil or a flat iron plate.

Punch needed to make it convenient to drill holes with an electric drill. This tool is pointed to the point where you want to drill the metal. Then they hit him with a hammer. From the resulting recess, the drill does not slip during the drilling of a metal part.

Hole punch set

Preparatory activities

A grass cutter from a lawn mower is made in a number of stages. Initially prepared in capacity where grass with branches will be ground:

- make markings on the bottom (along the perimeter) for four trapezoidal holes with rounded corners;

- holes are drilled in each drawn segment with a cross section of 1 cm;

- a jigsaw file is inserted into them and trapeziums are cut out;

- process cuts with a file or sandpaper;

- in the center of the bottom, a hole is drilled for the chopper shaft;

- a circle is cut out of a steel mesh with dimensions according to the diameter of the bottom;

- with the help of small scraps of a board or sticks, a prepared mesh fragment is fixed to the container from below;

- legs are made from metal tubes for the container, attaching them to the tank with bolts.

Wooden pieces are fixed with self-tapping screws, twisting them from the inside of the tank into metal bridges between the cut out trapezoids. In this way, the mesh is securely attached to the bottom of the container.

legs do it in the following way:

- bend the tubes in a vice or with a pipe bender in the form of the letter "P";

- the ends of future supports are flattened with a hammer;

- 2 holes are drilled in them on each side (6.5 or 8.5 mm in section);

- fit the blanks to the bottom of the tank and mark the points of bolted connections;

- drill at the hole mark;

- using bolts with washers and nuts, attach the steps to the casing.

After preparing the casing, in order to downsize created mechanism, perform the following operations:

- disassemble the trimmer, disconnecting the motor, rod and cutting nozzle from each other;

- a fragment about 20-40 centimeters long is cut off from the rod with a cable;

- collect motokosu;

- check the functionality of the equipment.

Chopper assembly

If, after assembly, the trimmer works well, then a grass grinder is created from it.

- The motokosa engine is attached to the board with clamps.

- Fix on wooden base a barbell, using clamps and a handle from a lawn mower for this.

- Connect the cutting nozzle to the end of the rod, previously inserted into the hole in the bottom of the casing.

- Start the mechanism and test it in operation.

After the done actions, the unit will be obtained, the photo of which is presented below.

If the trimmer used to assemble the shredder is equipped with a gasoline engine, then the motor is placed on the base so that it is convenient to fill in fuel, start the device and regulate its operation (speed).

Cutting nozzles are equipped with knives or fishing line - it depends on the thickness of the crushed plant stems.

What else can you make a chopper

There are many different options for creating garden shredders with your own hands: from the simplest ones, which only allow you to grind grass, to more structurally complex, powerful units designed for wood up to 10 cm thick. Accordingly, the practical implementation of the plan will require different details, different costs of time and money.

To collect equipment for processing plant waste, in addition to the considered options for old or unnecessary tools or equipment, you can use the following devices:

- drill or perforator;

- an old working vacuum cleaner;

- unnecessary power saw;

- pump motor;

- gasoline or electric walk-behind tractor;

- any electric motor of suitable power.

A drill with a perforator, if you use them to grind grass, you don’t need to redo it at all. It is enough to do just attachment with blades. The created device will work like a blender, grinding the soft stems of plants in a container in small portions.

The nuances of operating home-made equipment

A self-made shredder is essentially three in one: a chipper for branches, a straw cutter, a mechanism for cutting grass. It helps to significantly facilitate domestic work associated with the disposal of plant waste, as well as feeding poultry and livestock.

If you have to process grass in small quantities, for example, for chickens, geese, ducks, then it is enough and completely simple fixtures, which work from the muscular strength of a person, for example, a manual pruner.

For homemade electrical engineering, it is recommended to install separate differential machine to provide reliable protection against electric shock in case of unforeseen circumstances. In any case, when making a garden shredder yourself, you must follow the safety rules. It is also worth adhering to them during the operation of the mechanism. It is recommended to wear goggles, suitable protective clothing and check the reliability of fastening of the structural elements before working with the equipment. Should be taken into account when creating homemade unit the upcoming scope of work, as well as the nature of the processed vegetation, in order to select the engine of the required power and desired design knives. This will allow the device to be made without any problems to cope with the tasks.