The main space in the room is occupied by beds, and when the children were small, there was no shortage of free space. As children grow up, they need bigger beds. If there are two children in a family, then topical solution is the bunk beds, but they are expensive. And you can make bunk beds with your own hands - this is a fascinating and useful process.

Types of bunk beds

Now the furniture industry offers a lot of the most different models bunk beds. Based on these designs, it is possible to make your own version, ideally suited to specific conditions and the specifics of the room. The bed will be equipped comfortable stairs. In addition to traditional solutions, you can also build a loft bed that is popular today.

If we consider several options, then choosing the right model for a particular children's room will be much more convenient. Therefore, consider the most popular models.

traditional model

This bed for children represents the most simple design of all that are there. Almost anyone with minimal woodworking skills can make it. This model and others like it are good because they have a very small number of components.

The advantage of these models is that natural wood is used as materials - this is very important for children and their health. Wooden bed is environmentally friendly.

Bed with sofa

This model is distinguished by the presence of a folding sofa on the first tier. This saves more space in the room than the traditional 2-tier design. If there is an ordinary bed on the lower tier, it will not be too comfortable to sit on it - there is no comfortable backrest. Therefore, as an addition to the bed in the nursery, you will have to find a place for a sofa or chairs - this will take up enough space.

Bed with drawers

It is also one of the popular options for modern beds. This model designed for three children - there are three beds, and the design also provides drawers as well as shelves. This two-tier "monster" will take up a little more space, but it has cabinets and drawers - the child will put toys and his things in them. The scheme of a bunk bed of such a plan provides that the drawers will serve as a ladder - this is both compact and ergonomic.

Double bed on the first floor

This bed is not for children, but it can also be successfully used in small apartments. So, the solution is relevant if the apartment is 2-room and one of the rooms is allocated for the living room. On the ground floor of this bed is sleeping place for two adults, the second is a children's bed.

Bed in a large family

This 2-tier complex is designed for families with four or more children. A children's bunk bed of this level is much more complicated and much more materials will be required to build it, but due to this solution, the room will be very spacious, and the beds will be neatly placed along the walls of the room.

Loft bed

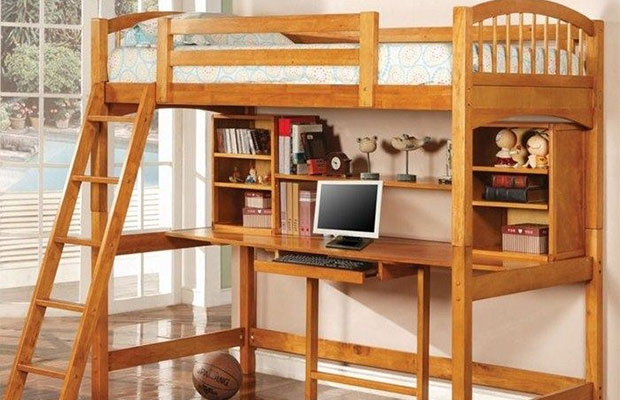

You can make your own loft bed. These beds are very popular with space savers. this nursery bunk bed installed for adult children. This solution is often chosen by adults in one-room apartments. The main difference of this model is that the bed itself is located on the upper tier, and under it work zone(table, cabinet, etc.).

On video: bunk bed models

Making your own bed

So, a suitable model has already been selected, it remains only to make components and assemble the structure. Let's see how you can make a bunk bed with your own hands. An instruction that goes into detail about every detail of the bed will help a lot. home master in this difficult task.

It is assumed that the model has been selected. The next step is to draw a sketch, but better detailed drawing bunk bed of your favorite design. In the development process, special attention should be paid to reliability, durability, comfort. The frame must be strong, the railing walls must also be reliable, and climbing stairs should not be difficult for a child.

Blueprints

Any work must be done neatly and accurately. For this there is an instruction and a drawing. More often drawings are created for each structural element separately. Exact dimensions details, overall dimensions will make it possible to achieve the intended result.

So. You can draw the drawings yourself - now there are a lot of different software. What is important in the drawing, what must be indicated on the diagram? These are the overall dimensions of the finished structure. It is also important to specify and develop a scheme for assembling a bunk bed. Must be specified necessary ways for interconnecting the elements of the bed, indicate the order of installation of the parts. You must specify the dimensions of each part and fasteners.

materials

To make a 2-story bed with your own hands, an array of natural wood is usually used. This is not only high-quality and natural, but also a beautiful material. Array processing may require special skills. As an alternative to the array, you can choose lumber - timber.

MDF is chosen for finishing - this is an analogue of natural wood, the material has an aesthetic appearance. Suitable laminated MDF boards. There is an option to use a raw plate. If parts for manufacturing will be ordered in furniture workshops, then MDF is processed there.

Chipboard is also used, but it is not suitable for all elements. You can make drawers, backs or panels from it. Along with chipboard, they also use furniture board- This is a sheet glued from several pieces. Its advantage is that it natural wood, disadvantage - special tools and skills are needed for processing.

Tools

Before you make a bunk bed with your own hands, you should prepare the tools. These are saws, a screwdriver, planers or Sander, knives, electric jigsaw and drill. You will also need a measuring tool.

Frame manufacturing

The process of working on the frame begins with the measurements of the mattress. The frame must strictly correspond to the shape of the mattress. If the bed is with a sofa, then measure the bottom of the sofa. The frame is connected to the sofa in its lowest part. Boards are prepared, which are then interconnected and represent a rectangle. Such boxes and their number should be made according to the number of beds.

Frame manufacturing scheme

Frame manufacturing scheme Next, the sofa is placed in the frame. To mount the sofa in the frame, use side stops - two bars installed vertically. They tighten with smaller bars. There should be two such supports - one on one side, the other on the second. Then the frame is fastened and pulled together.

Fixing can be done by any convenient way. Before using fasteners, wooden details coated with wood glue or PVA glue. Next, the entire structure is thoroughly dried.

Backs and walls

Headboards for beds can be different - rack options are often used. So, slats are added to the box at the bottom and at the top. They will hold the furniture, will protect from contact with the walls of the room. Often the back of the lower floor is soft.

For the manufacture of the back, take a furniture board or suitable boards. Next, a solid wall is made, which will be the restriction between the wall and the bed. Boards are fixed on the back of the box. The design of the back does not play a special role. This element is necessary for the selection of tiers.

Dimensional detail and assembly principle

Dimensional detail and assembly principle The side walls are ordered in the workshop - in this case, it is enough to fix them on the box. Professionals advise how to make side stacks - they can be solid for 2 floors. To make this element, take two boards - one should be wider than the other. Four rails are also needed. The boards intended for the headboard are installed from the sides into the rail. The second rail will mount the walls with other elements. Then connect the back and headboard. In order for the mattress to lie on the bed, lattices are made, slats or nets are installed. To enhance strength, the rail is nailed to the frame from the inside.

Stairs

Creating a do-it-yourself bunk bed, the drawings indicate the need for stairs. Traditionally, a ladder of three steps is used. But the number of steps can be more - this is the envy of the height. According to the type of fastener, the ladder can be vertical - it is tightly fixed on the frame. There are inclined stairs - these are installed at any angle.

Examples of drawings of stairs

Examples of drawings of stairs How to make a ladder is very simple. They take two beams - these are warps. Steps are fixed on them. The lower step is additionally connected to the rack of one of the backs. Others are located one above the other. The steps are simply inserted into the bars. Steps can be connected externally, in a recess or on metal corner. Any fasteners should be closed as much as possible. It is desirable that the stairs have railings - their design can be described in the drawing of the staircase itself. This is an ordinary wooden plank, calculated under the girth of the child's arm.

legs

These parts can be of various shapes depending on the model and drawing. These parts are fixed from the inside, outside, or they can be inserted into the box. In practice, round, square or carved details are chosen for bunk beds. Dimensions are considered for maximum reliability.

They take two bursas and connect them two by two. When the beams are connected along the length, the shape of the end of the part must correspond to the letter L. The length of the leg must exactly correspond to the height of the fence of the second floor. Here's how to assemble a bunk bed by making all its elements yourself. With the help of the instructions, everyone can make a bunk bed for children.

Step by step instructions for making a bed (1 video)

Need a bunk bed for a kid's room? You can go to the nearest furniture store and choose the right model at an affordable price. And you can save money by making a bed with your own hands, especially if you have the talent and skills of a carpenter.

How to make a bunk bed with your own hands?

- 4 timber 5 cm x 10 cm, 3 m long;

- 4 timber 5 cm x 10 cm, 2.5 m long;

- 2 boards 10 cm x 2 cm, 3 m long;

- 1 board 15 cm x 2 cm, 3 m long;

- 1 board 20 cm x 2 cm, 3 m long;

- 2 sheets of plywood, chipboard or MDF 2.5 m x 1.25 m for mattresses. Not less than 2.5 cm thick;

- Self-tapping screws 70-80 mm;

- Self-tapping screws for drywall 40 mm;

- 8 screws 15 cm with washers;

- 10 bolts with nuts and washers 8 cm;

- 2 bolts with nuts and washers 16 cm;

- Varnish, sandpaper, wood glue.

- Screwdriver;

- Saw;

- Level;

- Roulette;

- Construction pencil;

- Hands and head.

We measure the mattresses that you are going to use and leave a small margin of 1-2 cm. We get the size of our frame. We measure parts from the beams right size, sawed and fastened with long self-tapping screws.

We saw off wide boards according to the size of the length and width of the frame and fasten along the perimeter of the sides with self-tapping screws for drywall. For the upper bed, you can use wider ones.

For this children's bunk bed, we use one leg, as it will be mounted in the corner on two adjacent walls.

Measure the desired height distance at 10 cm of the bars and fasten them with screws to each other, as shown in the image.

Pre-drill a hole in the top frame assembly for attaching to the leg. Then drill a hole in the leg at bed height.

Drill holes in the assembled frames for wall mounting.

Screw the leg to the top frame and have someone hold the frame against the wall. Level the frame and mark the holes in the wall.

Drill holes in the wall and fix the top. Fasten the bottom one in the same way.

We saw off from the beam 4 pieces high under the upper fence. We saw off boards for fencing to size 10 cm. Attached to the bed.

Don't forget to leave room for the stairs.

Depending on the height of your bunk bed, the ladder may be different sizes. For my case, the dimensions are indicated in the figure. I attached the steps with bolts.

We connect the ladder to the bed and install the base under the mattresses. Your bed is ready!

A do-it-yourself bunk bed should be not only durable and comfortable, but also beautiful. Therefore, sand the visible parts and varnish, and it will retain its appearance for a long time.

Video: how to make a children's bunk bed.

- commodity prices are rising, and you want to live in comfortable living conditions. However, this is understandable, besides, many people are ready to do something on their own to bring benefits to the house. Well, in this article I will tell you how to do this and provide drawings and photographs of such furniture.

You can make such a bed for your children yourself

What is required for work

Of course, you understand that any furniture is made of something and something, and these components must be determined immediately. That is, before starting work, you need to prepare the necessary materials and select the required tools.

We select materials

OSB of various thicknesses

In fact, all materials must be from wood, that is, from lumber, but panel products may be different. I will just list what you can use, but you will have to choose on your own. So, we make a choice:

- bar 50 × 50 mm;

- board 50 × 70 mm (instead of a bar, but this is optional);

- board 100 × 50 or 150 × 50 mm;

- moisture resistant or laminated plywood or oriented strand board (OSB-3 or OSB-4) - you need a choice here;

- dowels with a diameter of 8 mm;

- self-tapping screws (it is better to take white or yellow ones, they do not rust, therefore, they will last much longer);

- wood glue or PVA, it may come in handy, but it may not, it all depends on the assembly method;

- varnish (see footnote!).

Attention! There are different varnishes, but do not forget that you are making a bed for a child! So, look at the sticker with the instructions, the varnish can be alcohol, alkyd, alkyd-urea, nitroglycerin, polyester, polyurethane, acrylic, oil and water. The latter is natural, therefore, it cannot harm a person when inhaled (it is safe not only for adults, but also for children).

What do you need from the tools

An electric jigsaw is more convenient than a manual jigsaw

Generally speaking, a hammer, a hacksaw and a curly screwdriver will be enough, but why complicate your life? Now there are many electric tools that will always come in handy in household and this:

- electric jigsaw and / or circular hand saw;

- screwdriver and / or electric drill with nozzles;

- set of drills;

- metric tape measure, pencil.

Note. Sandpaper or a grinding disc on a grinder may also come in handy, but this is not always the case.

Step by step assembly of the crib

In fact, the manufacture of a crib consists of stages, that is, first the different components are made, and then they are assembled. However, the factory assembly takes place in the same way.

Material dimensions

Layout of parts

- A - 4 legs 1730x76x38;

- B - pads for legs 1730x76x38;

- C - 2030x140x38;

- D - 1850x44x32;

- E - 914x140x20;

- F - 914x90x20;

- G - 1000x76x20;

- H - 1510x90x20;

- I - 482x64x20;

- J - 1800x90x20.

In addition to these details, stock up on such things as:

- grinder (belt or disc);

- clamps for fastening parts.

backs

Here you need to make planks from the bars

The backs are hammered into the dowels

The back at the head and the back at the legs are the same, you can just diversify them for beauty, for example, make an almost continuous crate at the head, and smaller at the legs. Instead of a crate, you can use LDSTP. Please note that the assembly is done with dowels and wood glue or PVA - they must fit tightly and they are hammered. There is one more nuance for the legs - if someone does not like to rest their feet on the crossbars, then they should not put the middle board, although this is not so important for children.

How to make side walls

Sidewall Image

Focus your attention on the bars that run horizontally across the stack - they are made using the block method. Such a device allows you to fix the bottom rails. Therefore, you should refer to the strength of the bars when buying them - there should not be cracks, rot and / or wane so that misfortune does not happen (the bottom does not fall out). You can even use a 50 × 70 mm board instead of a bar - it will be more reliable.

Make the wall itself from a cut sanded board 50 × 200 mm and again look at the quality so that there are no cracks, fungus and wane. You will need to paint the walls for manufacturing, but do not use nitro-varnishes - it is best to buy water-based preparations such as Aqua. You can also paint the walls with oil wax, but it will be much more expensive.

frame

Crib frame

The slats on the frame rest on the bars on the sidewalls, but they should be fixed with self-tapping screws so that they do not budge. As for laying, it should not be too tight, that is, the rail must be inserted by hand, and not hammered, because otherwise the lumber will creak from friction. They should not be varnished - all the same, the bottom will be made of chipboard, MDF or OSB.

Making a ladder

Making a ladder

Let's start with the fact that the ladder is generally a separate part of the structure, which should be easy to remove and just as easy to install in place. It is important here not to fix it permanently - the ladder can be easily detached, but at the same time hold on so that the child cannot fall off it.

Parts of the stairs

It's not difficult, just correctly calculate the slope and step of the steps. If we talk about the optimal slope, then this is 29-33⁰, although this is not a critical indicator (you can do it much steeper), and the steps for the child can be placed after 30-35 cm. Do not forget that the varnish itself is slippery, therefore Do not apply several layers - one will be enough. Below you can watch the video - this is one of the options for manufacturing products.

Video: Self-manufacturing baby crib

Another option

Let's look at a few more options - they are very similar, like all projects, well, well, a bed is a bed. Do not be afraid that all actions may seem identical - there is a difference and a very big one.

Selection of materials

Bunk bed option

At the moment, let's try to pick up the most common materials, although they can even be called the easiest in technical terms:

- solid wood (log) - the most good material, but it requires at least minimal carpentry experience and machines. At home, this is not available to everyone;

- finished lumber from a solid array - edged polished board and bars. GOST 17231-78 says that for such products, the humidity should not exceed 10-12% (no cracks, rot and wane). Otherwise, the lumber may twist with a “helicopter”;

- MDF is a finely dispersed fraction of lumber that does not produce chips when sawing and drilling. It has an average density, but it is more expedient to use it as a sheathing material. There are laminated sheets, but they are more expensive than usual - this is a matter of personal choice. Sawing can be ordered in a carpentry workshop (the edges will also be glued there), but this is easy to do on your own;

- Chipboard - chipboard without any coating. It has poor density, so such panels are not recommended for use under heavy loads. As the bottom of the crib or backs, it is better to use LDSTP (laminated boards);

OSB - oriented strand board. They are divided into 4 classes - OSB-1, OSB-2, OSB-3 and OSB-4. Only OSB-3 and OSB-4 are moisture resistant - this is an excellent material for a crib.

How to fasten knots

1 - half-tree docking, 2 - leg docking

Here are two ways to make docking: the first option is easier, and the second is more reliable. But on the paw, the joint will have to be cut with a jigsaw or a hacksaw for metal.

1 - docking with full cutting, 2 - docking with incomplete cutting, 3 - connection to a reinforced steel angle

For the first two methods, docking is best done using fixing with wood glue or PVA. The second method is more relevant when using self-tapping screws, but this is only for solid wood.

1 - docking on rectangular keys, 2 - docking of the "dovetail" type, 3 - docking on the main tenon

In this case, all connections are good, so you can use the one that is easier for you to make or just the one that you like best.

Several options with drawings

A little decor when cutting backs and walls

This option is already for professional carpenters

Here the child will have a place not only to sleep, but also to play.

Stairs and lower bunk can be used as bed linen or clothing cabinets

Video: Bed in the form of a castle

In the photos and videos, you can see that there are, in fact, no restrictions for design, but a lot will depend on your skill. You understand that most things are now being done on machine tools and special carpentry tools, which are far from being in every home. But if you wish, some parts can be ordered from specialists (you can’t buy them in a store).

And one more nuance - walkthrough, as such for the manufacture of a crib does not exist in nature. You can see for yourself that there can be many options, and everything will depend on your skill and desire (on financial capabilities too). But if you do not even have experience in carpentry, then this can be learned and the first step will be a sleeping place for your child or even for two offspring.

Conclusion

I think you figured out how to make a children's bunk bed with your own hands, and you can decide on such an experiment. The most important thing here is not to complex because of inability or fear of something new (you probably remember who burns the pots).

You have two children, but there is not as much space in the apartment as you would like? Then turn your attention to the bunk bed.

If you have two children, and the area of the apartment is small, then you can offer good decision- a bunk bed.

This piece of furniture will allow you to make the most efficient use of the available space and will surely appeal to children. With a little effort, you can make such a bed with your own hands.

Construction dimensions

Staircase to the second tier should be correct sizes made on the basis of calculations.

Before you draw up a project and the necessary drawings of the bed, you need to consider a number of important factors. First of all, choose a location for installation. Decide where the stairs leading to the upper tier will be installed. Based on these data, you can choose the optimal size of beds. It is important that the stairs have the correct dimensions.

The dimensions of the mattress and the bunk bed itself are calculated with a small margin. This will eliminate the need to assemble new furniture every 1-2 years. Usually a bed is made 180 cm long and 80 cm wide. A mattress 25 cm thick is considered optimal.

Prepare 2 pieces of foam rubber. One of them should have a thickness of 15 cm, the other - 10 m. Cut out rectangles of the desired sizes from them. For the top layer, buy foam rubber with a density of 45 kg / m³. For the bottom, 35 kg / m³ will be enough.

Next, you need to take a hard, strong fabric, sew mattress covers from it and insert foam rubber into them. It is better to use exactly 2 layers of foam rubber of different thicknesses, and not one 25 cm thick. For the most part, children sleep restlessly, and while awake they like to jump on the bed, so a single layer will wear out very quickly. Instead of foam rubber, you can use latex, batting or synthetic winterizer.

Given the area of the received mattresses, you will need to draw up a plan for the bunk bed, indicating on it all the details and their dimensions. Be careful at this stage. Eye measurements are not allowed here. You need to have an accurate idea of what it will look like finished bed, what dimensions it will have, how structural elements will be mated, etc.

The calculation of the required amount of materials will be carried out taking into account the following dimensions of the bunk bed:

- height - 185 cm;

- width - 90 cm;

- length - 190 cm.

You can change the dimensions to your liking, but don't forget to recalculate the amount of materials. It is very important to correctly determine such a parameter as the height between the crossbar of the lower tier and the bottom surface of the upper tier. It depends on the height of the child who will sleep on the lower tier. When getting up, the child should not touch the crown of the upper box. In most cases, it is sufficient that this distance is 85 cm.

Back to index

Preparation of materials and tools

The most reliable and durable for the construction of the bed are pine boards.

The best material in terms of price and quality is pine. You will need boards different sizes. You don't need to be tied to a specific length. Just write down what parts and how much you need. Based on this information, you can determine right amount each type of pine board.

If you have never worked with wood before and such work seems too complicated for you, you can replace the pine board with chipboard. In this case, you will save yourself from performing time-consuming operations associated with the processing of pine. You just need to be careful, and the finished bed, in terms of its characteristics, will be no worse than an expensive product from the store.

You will also need to make a base for the mattress. To do this, buy a pair of plywood sheets 185 cm long, 90 cm wide and 0.9 cm thick. In addition, you need to purchase 3 steel pipes with PVC coating, screws 40x3.5 mm, glue and decorative caps.

The boards that will be used to assemble the bed should be allowed to rest in the room for at least a week. This will allow them to get used to the humidity and temperature conditions and prevent possible deformations.

Pine board is considered an excellent material that is great for self-assembly of a bed. However, it must be remembered that any furniture requires high-quality and correct processing, such as sanding, leveling, processing with protective agents, painting, etc. So in order for the work to go quickly and easily, and the finished bed to serve for many years, you need to prepare a whole set of tools:

- screwdriver;

- drill;

- hacksaw;

- saw;

- grinder;

- building level;

- roulette;

- magnet.

Back to index

Calculation guide

The mattress will be laid on the bars (bed). To make a sunbed, you need to prepare a board 140x18 mm. Each tier should have 9 boards. They will ensure maximum stability of the bed. In this example, the bed has a width of 80 cm. The sunbed should be slightly smaller so that in the future you do not have to hammer the boards with a sledgehammer.

The sunbeds will be laid on 3x3 cm bars. Sides and ladders are made of 8x4 cm boards. The exact amount of materials depends on whether the side will be installed on the lower tier, as well as on the location of the ladder. In this example, the ladder is installed on the right. Along the perimeter, the structure will be pulled together with a massive board 14x4 cm. From such a board you will make drawers. They will act as mattress pads.

Calculate the required number of the above elements in accordance with the dimensions of the future bed.

Furniture made from chipboard will weigh 2-3 times more than a similar product made from natural boards. However, its final cost will be 5-10 times lower.

Back to index

Step by step assembly instructions

During work, you will definitely need an assistant. First, measure the mattresses and add 1.5-2 cm to the data obtained on each side. This is how you determine the dimensions of the frame. If there is such an opportunity, it is better to ask immediately to cut the materials at the place of purchase. If this is not possible, do everything yourself, but be careful. Don't throw away the cuttings.

Take bars 5-10 cm in size and connect them with screws. As a result, you should get 2 frames for your homemade bunk bed. In order not to get confused in the next steps, be guided by the diagram in Figure 1.

Attach a 15x2 cm board to the end and one side of the frame with screws. The fastening should be as reliable as possible. Self-tapping screws should not go through the side board, this is very important. In case the length of your self-tapping screws turned out to be not as needed, take a drill and drill holes in the frame bars of a slightly larger diameter. Use the depth gauge for this. If your drill does not have such a function, simply wrap tape around the drill in the right place. On the second frame, install a 20x2 cm side in the same way.

Factory bunk beds, as a rule, are equipped with legs made of boards measuring 10x2.5 cm. The model in question is designed for quite serious loads, so it is better to make legs from a pair of bars measuring 5-10 cm. Connect 2 bars along the length to make the resulting end was L-shaped. Holes from fasteners are sealed with putty and plastered. As a result, the length of the leg should be the same as the height of the fence located on the upper tier.

The hole for the leg of the bed should be at the height of the top bunk.

Next you need to drill a hole in the leg. It should be located at the height of the attachment of the upper tier. A hole about 20 cm high is made in the frame with a side. Drill a recess in the leg. It must be deep enough. This way, the washer and screw head will not be visible, and the screw itself will be able to pass through the leg. Screw in the screw.

After that, you need to mark the places for drilling where the rack profiles will be located. It is at this stage that you will need an assistant. He will support the frame from below and press it against the walls. It is important to correctly set the frame using the building level. Drill pilot holes so that hex head screws can be screwed in later. To drill through the frame beam, post and wall, you will need a fairly long and thin drill bit. Screw in screws. They must be fixed in the rack profiles. In the same way, install the lower tier of the bed.

Sometimes the situation of standard premises requires non-standard solutions. This is especially true for children's rooms in large families. After all, there you need to organize a place for games and sleep. Bunk beds come to the rescue, which save precious square meters.

What should be a children's bed - MDF, chipboard or solid wood?

Despite the variety of factory cribs in two tiers, it is not always advisable to buy them. The purchased model may not fit into the interior of the room, and the cost can be unreasonably high. However, there is a way out -. Even if this is not easy: you will have to study the specialized literature, select materials and assemble a set of tools.

You can draw a lot of sketches of children's beds, at least one, at least two floors. But there are conditions common to all models:

- Comfort. Children should be comfortable. Their health, both physical and psychological, depends on it.

- Beauty. This is important in shaping the character of the child, regardless of his gender.

- Safety. It is not only about the reliability of the design, but also about the correct selection of materials.

In fact, there are more requirements for children's furniture, but these are the main ones. And in many ways, the quality of the crib depends on the materials. Traditionally, MDF, chipboard, and solid wood boards are used in the manufacture. Great option furniture is considered. It is an environmentally friendly, breathable material. When buying, choose high-quality, dried wood without external defects (knots and cracks). Wooden beds have high thermal conductivity and remain warm even in a cool room. Hard woods such as birch, beech, ash are considered optimal when making a bed with your own hands. The main disadvantage of this material is the high price.

Not so long ago, chipboard was the most popular material in our country. From it they collected kitchen and bedroom sets, furniture for residential and industrial premises. However, furnishings made of chipboard are not always safe for a child's health. Often the composition of this material includes the toxic substance formaldehyde. You can determine its presence by smell. In addition, chipboard furniture is not durable and aesthetically pleasing. appearance. By and large, the advantage of this material lies only in the low price.

An alternative to chipboard is MDF boards. This material is made from dried fine wood pulp and pressed into boards. Lignin, a natural resin obtained from trees, is used as a binding element. V furniture production, as a rule, laminated MDF boards are used. This one is relatively inexpensive material, but at the same time it is spared from the shortcomings of chipboard.

Options for the nursery - 2 popular models

Independent production of a children's bed begins with sketches. Drawings and methods of creation comfortable furniture we will look at below. By the way, not always a children's bed in two tiers is installed in a room where two or more children live. The reason may be to save space or create a room original interior. There are many options, but we are going to make a bunk bed for the first time, which means complex structures better to avoid. Our task is to create a reliable and convenient design without any frills. Consider two models that are popular in the design of a children's room.

Classic bunk bed - sleeping places are equipped on the first and second floors. This design is simple and reliable. For its manufacture will require a minimum of materials. This model is stable, and it can be used for games and room zoning. For reliability, it can be attached to the wall.

Bed in two tiers of attic type. It is designed to save square meters in the room. On the second floor of the structure, a sleeping place is created, and on the platform of the lower tier, the child can work or play. This design is suitable for both preschoolers and teenagers.

Of the tools for assembling a bunk bed, we need a tape measure, a pencil, a screwdriver, a hacksaw (electric jigsaw), a hammer, pliers, an electric drill with a set of drills, a square, a grinder. Such a set will be required when creating any model. Save on materials is not worth it. We make a bed for children. Therefore, the design will be based on natural wood, MDF boards or combinations thereof. Chipboard will be left for industrial premises. With the right approach, our crib will not yield to models made by factory manufacturers.

General principles for assembly - first about the main thing

Despite the variety of wooden beds, their assembly is carried out according to general principles. The boards and bars from which the bed is assembled must be smooth and of the right size. When attaching the transverse boards for laying the mattress, side rails are used - side stops. And it is better to make them from beams. Cross boards for laying the mattress, drawers are used - side stops. And it is better to make them from bars.

When assembling, apply carpenter's glue to the sides, and fix the laid boards with clamps. After the glue dries, remove the clamps, and screw the screws in their place. Almost all self-tapping screws or screws are screwed "in the sweat". That is, their caps should be flush with the surface. To do this, first drill a recess with a large diameter drill. In the future, the head of the self-tapping screw can be masked with a special decorative plug or putty.

Special requirements are imposed on the legs - the side end panels of the structure are attached to them. Therefore, preference is given to hardwood blocks. We fix additional stops on them or cut grooves. Giving the design of attractive smoothed forms for novice craftsmen often causes difficulties. Patterns made of cardboard or thick paper, prepared in advance, will help to cope with this problem. It is desirable to cut grooves in the board with an electric jigsaw - the cut line will be neater. And the resulting cut is processed with a milling cutter (or sandpaper). This applies to all structural elements.

After preparing the details of the bed, we carry out a preliminary fitting and apply markings. After making sure that all the details correspond to the drawing, we proceed to the assembly. To do this, we use connecting dowels. We mark the holes for their installation with a pencil, and then drill them. Initially, we leave the grooves and dowels dry, but we use them during the final assembly.

We assemble the bed in stages, starting from the first tier. The assembled and glued base is tightened with clamps until completely dry. And after their removal, the elements are fixed with self-tapping screws. In fact, before the final assembly, the bed can be assembled and disassembled more than once.

Assembling a classic bunk bed - step by step guide

So, let's try to assemble a classic-type bunk bed. Its manufacture will allow you to "fill your hand."

The assembly of such a bed begins with the manufacture of the base. We make drawers and attach two boards to them at an angle of 90 °, our task is to create a rectangular box. We fasten the bars - supports to the end boards with self-tapping screws. And in the created box (base) we mount the crossbars, on which the mattress will later lie.

The next step is to create the back. Let's take three boards (their width should correspond to the size of the bed) and assemble them with the bed posts into a single whole. As a rule, we use dowels for this. You can cut them yourself or buy them at the store. We drill holes in the boards and racks, into which we insert the dowels. Attach the boards to the bedposts and make the appropriate marks with a pencil. Do not forget that a preliminary fitting is initially carried out, and only then the fasteners sit on carpentry glue.

Having finished working with the back (headboard), we proceed to the manufacture of the footboard. In fact, its manufacture is not much different from the creation of a headboard. The difference is only in the number of boards of the crossbars. But at the same time, it is important that the upper boards of the back and footboards are on the same level - the base of the second tier will stand on them. The second tier is made in the same way as the first. But it is placed on horizontal bars and fixed with dowels. After fixing the second tier, we will strengthen the structure with end boards - racks. Having finished assembling the bed itself, we install the ladder. There are many options for manufacturing this structural element. Let's stop at a simple one - we attach horizontal crossbars to two vertical posts.

The final stage is decoration. For these purposes, we use paint and varnish products. When choosing paint or varnishes, give preference to water-based coatings. They are safe for health. And for us, this is a key parameter.

The given instruction is not a standard. Based on it, you can develop a sketch of a bunk bed of your own design. There are options where the first tier is replaced by a sofa or a work table. However, the last case concerns an attic-type bed.

Production of a two-story variation of the "attic type"

This type of bed allows you to save space in the room. But an interesting design makes it popular not only in small apartments. Loft beds are not uncommon on college campuses. By the way, on the second tier, as a rule, they make one bed, but other options are possible. When creating a bed, a lot depends on skill. Perhaps you are ready to take on complex project with many decorative or functional elements. However, if this is the first experience of this kind, it is better to dwell on simple models.

There are loft-type beds that are attached to the wall or directly to the ceiling. We will focus on the usual model, where the bed is an attic, this is a structure of four supports of 1.5–2 meters and a berth. Work on the bed will begin with the creation of drawings. In this case, special attention should be paid to the dimensions. After all, the comfort of the workplace located on the ground floor depends on the height of the structure. A bunk bed for a preschooler should be created taking into account that he will grow up.

Step-by-step instructions for its manufacture are not difficult:

- 1. prepare the tree - grind with sandpaper, cover with an antiseptic;

- 2. in accordance with the drawings on the racks, we prepare places for fastenings (we drill holes for dowels);

- 3. we make a sunbed - the assembly scheme is the same as in the manufacture of a standard bed;

- 4. we assemble the bed and the support racks into a single whole. In this case, the upper edges of the racks should be 30 cm higher than the sunbed;

- 5. we want the top and bottom straps. That is, we fasten the support posts of the board at the bottom (the number and dimensions depend on the load). They will give the structure additional rigidity. At the top, the same boards will serve as sides for the bed;

- 6. install the ladder.

When you finish assembling the structure, cover it with a transparent varnish. A rare material can compete with the beauty of a tree pattern.