Each house is equipped with an electrical system. Wiring is usually mounted from scratch or replaced with a new one. The electrical wiring system must not only distribute electricity correctly, but also be highly secure. The protective function is performed by the electrical panel. It must be installed in every home. Professional electricians perform high-quality assembly of electrical panels, however, subject to certain rules, such work can be done independently.

When creating high-quality wiring, you should understand how the physics of the process is carried out. Engineering knowledge consists of understanding the basics of physics and mathematics. Therefore, it is possible to conduct wiring on your own only with full possession of certain knowledge. It is important to use specific recommendations and follow certain rules. Requirements for electrical panels are prescribed in the relevant GOSTs.

What is the shield for?

Several systems can be called an electrical panel. These include the switchboard, main and group. They all work on the same principle. What is the electrical panel for? It has several features:

- It must receive energy from an external source.

- The electrical panel is used to distribute energy to different groups of consumers;

- Another function of the shield is to protect the wiring. It prevents short circuits.

- Modern shields are able to monitor the quality of the energy supplied to the consumer, and, if necessary, react to it.

- The electrical panel must guarantee absolute safety, protect people from many damaging factors.

A small device must meet many requirements. This requires a careful and thoughtful approach to working with the electrical panel. Installation of the device will not do without an accurate scientific calculation. However, all complex concepts and processes can be presented in the form of simple recommendations. The main requirements are spelled out in GOST.

How electricity is distributed

The distribution of energy among user groups is one of the main tasks of the electrical panel. If you decide to install it yourself, you should know a few mandatory distribution rules:

Many may think that this approach to mounting the shield and running electrical cables is rather redundant. However, in reality, this method is the only true one, given the need to ensure the safety and comfort of control prescribed in GOST.

Many inexperienced electricians who are unfamiliar with the principles of wiring, in order to save money, purchase cables of small gauge instead of quality products. In addition, amateurs often purchase RCDs and low-cost machines. Such decisions may affect the safety of residents of a house in which electricity is supplied.

Before wiring, consider one example. A cable with a cross section of 1.5 square meters comes out of the shield. mm, which is protected by a 10 A machine. It can be used for lighting in one room. The line enters the junction box. If in the next room the load on the electrical network is expected to be less, an inexperienced electrician may decide to reduce the cross section of the cable leading out of the junction box to 0.75 square meters. mm.

For unknown reasons in electrical network a short circuit occurs. The wires can simply pour from the apartment above. The cable begins to experience the action of strong currents, reaching up to 10 A. It does not withstand and lights up. The cable insulation melts, and a fire can start in the apartment. It follows from this that there should not be a decrease in the cable section in the line under any circumstances.

Electrical panel diagram

When installing the shield and wiring, you should correctly draw up a diagram. This work is usually assigned to a specialist engineer. However, subject to certain principles, it is performed independently. The wiring diagram and the shield must be accurate. This will ensure the safe operation of the system.

One of the simplest is the single-line shield diagram. You can understand it pretty quickly. The name "single-line" appeared because in such a scheme, a group of wires is immediately indicated by one line, and not individual electrical cables. How many wires are in it, shown with slashes. At the bottom of the diagram, power, type of cable and consumer lines are signed.

To protect the electrical system from overvoltage, circuit breakers are used to open the electrical network under load. It is not recommended to use them everywhere, since they react quite painfully to shutdown under load. It is better to install electric machines.

To understand the connection diagram of the electrical panel with all current consumers, you should look at its more attractive version. This diagram shows all electrical devices and conductors. The scheme of the electrical panel must meet the requirements of GOST.

The need for an RCD for an electrical panel

RCD is a device that cuts off power when certain values are exceeded. It is able to recognize the leakage on the electrical network. It must be installed on all socket and power electrical lines. You need to know a few rules for choosing and operating such a device:

The use of differential automata is not justified from the economic point of view. It is better to buy RCDs and machines separately. You can install a differential machine only with an acute shortage of free space in the shield. Such a device can also be used in the protection of critical electrical lines.

Advice! After developing the electrical panel diagram, you should get advice from an experienced electrician. This will avoid many problems in creating high-quality electrical wiring.

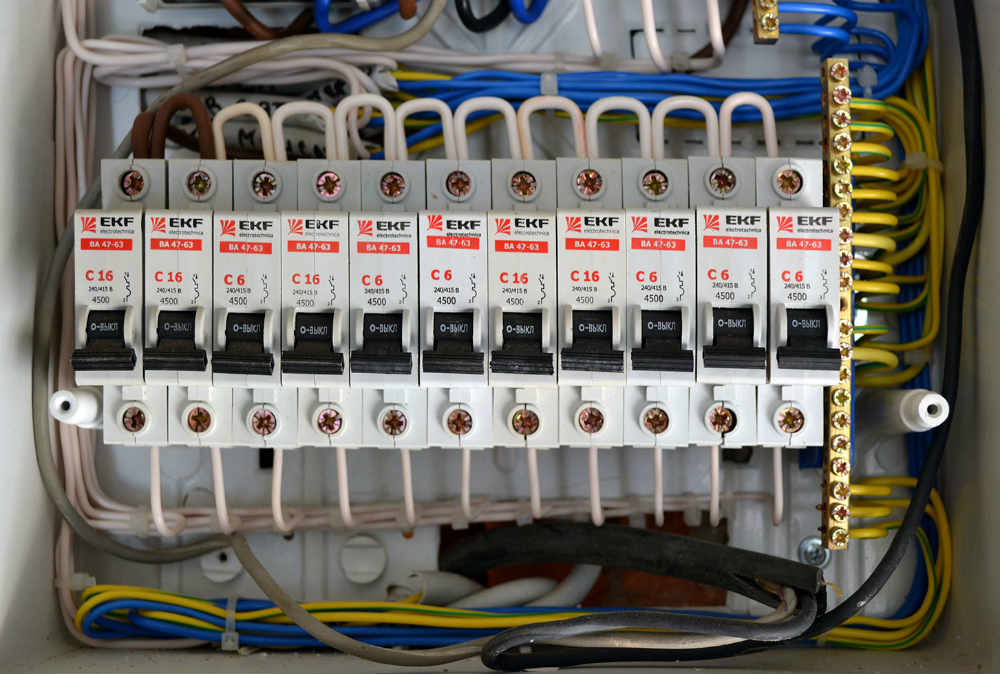

Number of seats in the shield

Each device installed in the electrical panel is carried out standard sizes. All elements are located in a metal profile. Its width is 35 mm. This width is enough to install a single-way circuit breaker in a shield. The main parameter of the electrical panel is the number of landing modules. To find out how many such places are needed, you should use a special table.

It is better if a modular socket is installed in the shield. It needs 3 spaces. Such a device may be needed when performing repairs. With such equipment, you can easily turn off all lines and connect a power tool to the shield. This will require an extension cord.

In addition, you should install a voltage relay that will monitor its readings on the network. If the voltage goes beyond the set limits, the load will be turned off. After a certain period of time, the voltage will appear again. This saves valuable energy consumers.

Even when installing a simple shield, 20 places will be required. However, professional electricians recommend choosing shields with a margin so that you can add a line later. Therefore, it is better to purchase a shield for 24 or 36 seats.

Choosing a good electrical panel

When the number of seats is determined, you should think about the design of the product. There are several types of shields distinguished by the method of installation:

- Hinged shields, for which it is not necessary to prepare a special niche. They can simply be hung on the wall using screws or anchors. When installing a shield on the street, you should make it hinged. If it is mounted indoors, the wiring must be open.

- Built-in shields- for such devices prepare a niche in the wall. Such products are mounted exclusively in rooms with hidden wiring.

Shields are often made with a metal case. They are made different types- built-in and hinged. Due to the increased strength of the case, they have a certain advantage over models made of other materials. Especially often they are installed on the street. These shields are much easier to protect against vandals. Outdoor models are usually equipped with a glass window that allows you to read the meter data.

Shields made of plastic are very popular today. They can be mounted or built-in. Such devices are intended for both outdoor installation and indoor installation. Due to the wide variety of models, they can fit into almost all interiors. Usually they look very aesthetically pleasing. However, after a few years, the white plastic may turn yellow.

There are several tips on how to choose an electrical panel:

- First, you should pay attention to the seller. From a trusted supplier, you can immediately purchase an electrical panel and modular equipment, and many accessories. It is better if the purchase is carried out in a large store, which has a fairly large assortment. Such sellers care about their reputation, so they will not be able to find low-quality products.

- It is also important to consider the manufacturer. Among the world brands are Hager, Makel, ABB. However, there are several proven domestic manufacturers.

- Each manufacturer offers shields with different configurations. It is better to choose products with rich functionality. In such a shield, the rails should be in a frame that can be easily dismantled. Such constructive solution simplifies assembly and dismantling of the structure. In addition, you should choose a shield with the correct organization and locking mechanism for incoming cables. It is better if there are cable organizers in the shield, which will save space inside the structure.

Many well-known manufacturers also produce related products - locks, combs, doors.

Assembly and installation of the shield

The electrical panel is a complex device that requires precise assembly and correct installation. Do not pack the device with modular equipment in a dirty or dusty area where construction work is being carried out. It is better that these processes take place in a clean and well-lit room, on a sturdy table. That is why it is better that the shield is equipped with a removable frame with rails.

Mounting the shield housing

Hanging structures can be installed in a few minutes. Such work is no different from hanging a conventional locker. Therefore, an embedded design was chosen as an example. The technology of its installation in a brick or concrete wall is not different.

Installing a shield in a concrete structure is a little more difficult. First you need to find out if the wall is load-bearing or not. In the first case, the installation of a shield in it is prohibited. Upon approval, it will be necessary to carry out reinforcement according to the new project and carry out various works. This will take a lot of time and financial costs.

It is better if the shield is mounted in a false wall. All necessary cables can be laid in it in such a way as to ensure maximum efficiency of the shield operation. In this case, the wall will become 10 cm thicker. Such a solution can be advantageously beaten from a design point of view.

First, you should consider the rules for assembling an electrical panel with your own hands:

- Shields should be placed in ventilated rooms, placing the structure near the entrance to the dwelling. It is better if the shield is installed in the vestibule.

- The room in which the shield will be mounted must have a humidity of 60%.

- From doorways, corners and slopes to the side surfaces of the shield there must be a distance of at least 15 cm. In addition, the device must be easily accessible. It is not recommended to install shields in cabinets or wardrobes.

- Easily flammable objects and substances should not be placed near the shield.

- Installation should be carried out at a height of 1.4 to 1.7 m above the finished floor.

The installation of the electrical panel is a complex procedure that is performed in strict sequence. Each stage of work should be carried out as accurately as possible, without missing the smallest detail. The procedure for mounting the housing is as follows:

- Mark the location of the shield. To do this, with the help of a level, draw the line of the bottom of the structure and the vertical of any side.

- Attach the body to the wall. Align the bottom and side edges with the markings. Outline the body along the perimeter. To do this, use a building marker.

- With the help of a grinder, cuts are made along the perimeter of the niche. For this work, a grinder with a diamond disc is used.

- Using a perforator, it is necessary to hollow out the entire surface of the niche, and then level the bottom.

- Try on the case in a niche, check how optimal the installation depth is.

- Install a standard mount on the shield, and then insert the shield into the niche, level it and make marks in the wall for dowels.

- Using a puncher, drill holes for fasteners, insert dowels, install the shield and fix it.

- Dismantle the frame with the rails inserted into it from the shield.

- Fill the space between the niche and the housing with mounting foam.

Often there are situations when wall mounts are not supplied with the shield. You can install the shield on the dowels, punching them through the back wall. For fasteners there are places in which holes are drilled.

Entry of cables into the shield

This procedure requires a lot of attention. With the correct organization of cable entry, the installation of modular equipment will be greatly facilitated. This will allow you to correctly install the necessary devices.

Standard shields are made in such a way that it is convenient to insert cables into them. There are special perforated holes in the lower and upper parts of such structures. To insert the pipe, you just need to press them with your finger. Typically, such holes are designed for pipe diameters of 16 and 20 mm.

Entering the cable into the hinged electrical panel is quite simple. The electric cable only needs to be fixed and the cables to be inserted methodically one by one. When entering a cable into a built-in device, a certain technology follows. In this case, the body of the shield must be fixed to the alabaster. In addition, it must be leveled. This job is best done by a professional.

If you buy a cheap shield, it will be problematic to introduce electrical cables. The holes will have to be cut by yourself. Then you need to install special plates. All difficulties can be avoided if you immediately purchase a more expensive design that meets all the requirements of GOST.

Another problem that inexperienced electricians face is introducing an electrical cable into the electrical panel when passing technological holes, the cable has a certain degree of freedom when it moves in the pipe. At the same time, it is difficult to organize the wires in the electrical panel itself. This problem can be solved quite simply - it is necessary to throw alabaster into the strobe near the place where the electrical cables enter the shield. However, this solution is not very modern and not the most effective.

Pre-assembly of the electrical panel

There are many photos on the Internet that illustrate the assembly of electrical panels already installed in their places. In this case, it is necessary to arrange the modular equipment and perform switching various elements wire PV1. Its cross section should be from 4 to 6 square meters. mm. Equipment is being installed at a height of 1.5-1.7 m from the floor. This must be taken into account, knowing that at the same time painters and putters will be walking around. In fact, the installation of an electrical panel is very difficult to carry out even for an experienced professional.

Conclusion

Considering all the problems that you may encounter in the process of work, it should be recalled that it is better to purchase only high-quality components. Modular equipment must be installed on a table in a clean room. The experience of such work will allow you to connect all the lines to an existing shield.

Magnetic starters, relays and contactors are one of the most extensive groups of switchboard equipment. For the correct operation of these devices, it is required to comply with a number of wiring rules, knowledge of the basics of relay technology, as well as a competent approach to organizing power supply circuits for electrical appliances.

Types and classes of contactors

Contactors are designed for remote or automatic switching of power supply lines of high power electrical appliances. These electrical products include panel-mounted devices with practically unlimited power, as well as modular devices for mounting on a DIN rail. In the latter case, the permissible current, as a rule, is no more than 63 amperes. Small (non-modular) DIN rail contactors are rated up to 100 A and are really panel-mounted products for a fairly simple reason: their dimensions do not allow the front panel of the shield to be correctly replaced in place.

Left: 63 A DIN rail modular contactor. Right: panel mount contactor

Left: 63 A DIN rail modular contactor. Right: panel mount contactor

The generally accepted classification of magnetic contactors implies their division into values corresponding to the standard size and permissible current load. So, modular devices are limited to the 4th value, there are 7 in total, with maximum dimensions the contact group is designed for currents up to 250 A. Outside the general classification are contactors capable of switching circuits at a current of 1000 A and above, but such devices have a narrow industry application and we will not consider them.

Separate models of contactors may have differences in electrical insulation class and permissible switching voltage. There is also a difference in the operating voltage for which the coil of the retracting electromagnet is designed. Additional differences are:

- the number of switched poles of the power group of contacts (from 1 to 4);

- response time (from 0.01 to 1 s);

- type and efficiency of arc suppression devices for different degrees of load inductance;

- permissible number of switching cycles per hour;

- noise and vibration levels;

- the presence and number of additional low-current contacts.

The device of a three-pole contactor with normally open contacts: 1 - coil; 2 - fixed magnetic circuit (core); 3 - movable core; 4 - fixed contacts; 5 - dielectric holder of moving contacts; 6 - moving contacts

The device of a three-pole contactor with normally open contacts: 1 - coil; 2 - fixed magnetic circuit (core); 3 - movable core; 4 - fixed contacts; 5 - dielectric holder of moving contacts; 6 - moving contacts

The concepts of contactor and starter reflect different essence. So, the name contactor implies a device in a monoblock design with only the set of functions that are provided for by the design. The starter is a complex of devices combined within a single control assembly. It may include several contactors, as well as additional prefixes, protective devices, controls and housing with a certain degree of dust and moisture protection. Starters, as a rule, are designed to control the operation of asynchronous electric motors.

Basic concepts about installation

A contactor or starter is almost never the only element of a control circuit. A prerequisite is the presence in the circuit circuit breaker, the value of which is calculated based on the limiting current of the contactor. It is also important to choose the correct current-time characteristic of the protective shutdown, it must correspond to the resistance class of the contactor to inductive loads.

Magnetic contactors are designed for natural air cooling, and therefore the place of their installation must have sufficient internal volume or have ventilation holes. Also a prerequisite is the absence of vibrations of the base to which the contactor is fixed, otherwise unintentional rejection of the retracting rod with subsequent opening of the circuit is possible. Finally, the operating conditions of the contactor must correspond to the class of its protection from external influences, because the internal mechanism is extremely sensitive to moisture and dust, especially abrasive and conductive.

Switched load connection

The connection of the power circuits of the contactor is carried out, as a rule, by screw terminals with a clamping bar or a saddle. When assembling the power circuit, it is recommended to take maximum measures to ensure the maximum area of contact between the cable cores and the contact pad. So, it is better to roll single-wire conductors into a half ring, and multi-wire conductors - to compress with a flat pin tip.

The group of power contacts on each pole is represented by two fixed and two movable, connected by a conductive plate. Thus, the contacts of each phase are located in parallel, their clamping screws are located on the front of the case and are marked with the letter L with the corresponding digital index. The tip of the core is inserted under the clamping bar or into the saddle until it stops, after which it is clamped with a screw. For rated currents above 63 A, it is recommended to use a torque tool. Power contacts need to be tightened after 48 hours to compensate for residual deformations of the metal.

As you can see, the connection diagram of the power section is extremely simple: the contactor switches the phase lines, the working zero is collected on a common bus or cross-module. The only difference is valid when assembling circuits with an isolated neutral, in such cases the working neutral conductor is switched by the fourth pole of the contactor.

Control circuits

Electromagnetic contactors do not have a mechanical lock in the on position. To ensure the retention of the rod during operation, a self-catching scheme is used. This is a fairly convenient technique that allows you to switch the power circuit of the coil various devices protection and automation of the electric drive. The exception is assemblies controlled by PLC or relay automation.

The simplest self-locking circuit includes one additional blocking normally open contact. The power supply circuit of the coil is connected through the normally open contact of the start button. The second circuit is connected in parallel, it consists of a blocking contact connected in series and a normally closed contact of the Stop button. Thus, when the contactor is turned on, a blocking contact is closed, which is held all the time of operation and supplies power to the coil. If it is necessary to stop the power circuit of the coil, it is opened with the "Stop" button.

Contactor self-pickup circuit: L1, L2, L3 - phases of a three-phase power supply; N - neutral; KM - magnetic starter coil; NO13-NO14 - additional normally open contact; M - asynchronous motor

Contactor self-pickup circuit: L1, L2, L3 - phases of a three-phase power supply; N - neutral; KM - magnetic starter coil; NO13-NO14 - additional normally open contact; M - asynchronous motor

There are also more complex control schemes. So, the use of a normally closed contact of the start button of one contactor can be used to exclude the simultaneous operation of two starters, which in particular can be important when building reverse switching circuits or be due to other technological necessity. The same principle can be applied by using the normally closed blocking contact of one contactor, which is connected in series with the start button contact of another.

Scheme of reversing engine start: KM1, KM2 - coils of magnetic starters; NO KM1, NO KM2 - normally open contacts of starters; NC KM1, NC KM2 - normally closed contacts of starters; KK - thermal relay

Scheme of reversing engine start: KM1, KM2 - coils of magnetic starters; NO KM1, NO KM2 - normally open contacts of starters; NC KM1, NC KM2 - normally closed contacts of starters; KK - thermal relay

Limit switches, dry contact sensors and all kinds of protective devices can also be included in the self-pickup circuit. Automatic switching on of the contactor is also possible; for these purposes, the button is replaced or duplicated by the parallel connection of limit switches or sensors. Thus, the complexity and control schemes of an automated electric drive are practically unlimited.

Additional devices

As already mentioned, the contactors themselves have an extremely simple design and may only consist of an electromagnetic retractor and one or more pairs of power contacts. At the same time, there is an impressive number of additional modules that can expand the original functionality far beyond the limits of conventional switching.

The most common attachments with additional blocking contacts. If the contactor does not have these initially, this type of equipment is the only way to implement a self-retaining circuit. Also, additional auxiliary contacts can be used to implement more complex control, indication and automation schemes.

Another popular type of additional devices is thermal releases. Their task is to control the load flowing in the circuit and turn off the power to the coil when the permissible current values \u200b\u200bare exceeded for a long time. Like the thermal releases of circuit breakers, attachments for contactors have different current-time tripping characteristics for different types asynchronous motors. Electromagnetic releases are not used as add-ons because the contactors are not designed for switching short-circuit currents.

Auxiliary devices of the contactor: 1 - thermal overload relay; 2 - contactors; 3 - prefix time delay; 4 - auxiliary contacts

Auxiliary devices of the contactor: 1 - thermal overload relay; 2 - contactors; 3 - prefix time delay; 4 - auxiliary contacts

Time delay prefixes make it possible to implement slow start and stop circuits of the electric drive. The time relays have the ability to manually adjust in a certain range, which allows you to accurately adjust the compensation of the inertial run-out of the electric motor before reversing.

Of the additional devices, we should also mention attachments for mechanical interlocking of the counter-connection, using which it is possible to assemble a reversing starter from two conventional three-pole contactors. If control is carried out directly from a cabinet or switchboard, starters can be used in which a group of connections for self-pickup has already been made and the “Start” and “Stop” buttons have been installed. If the contactor coil does not match the operating voltage of the control circuit, it can be easily replaced with another one with suitable parameters. Additional motor protection is provided by monitoring and phase sequence relays, as well as surge suppressors.

Basic wiring diagrams

There are three power switching schemes in total, according to which contactors are connected. The first and simplest is direct phase switching, which is suitable for both one-sided drive start and active load control. There is nothing remarkable in the circuit, the contactor simply acts as a remote switch.

An example of the use of contactors in the generator autostart circuit: 1 - introductory machine; 2 - counter; 3 - RCD of the main network; 4 - main input contactor; 5 - block auto start generator; 6 - gas generator; 7 - RCD of the backup network; 8 - time relay; 9 - backup input contactor

An example of the use of contactors in the generator autostart circuit: 1 - introductory machine; 2 - counter; 3 - RCD of the main network; 4 - main input contactor; 5 - block auto start generator; 6 - gas generator; 7 - RCD of the backup network; 8 - time relay; 9 - backup input contactor

A slightly more complex circuit is used to control the forward and reverse rotation of three-phase asynchronous machines. Two contactors are installed in pairs, outgoing phase wires are connected in parallel. In this case, the connection from the power supply side is carried out by a cross jumper, which changes the sequence of any two of the three phases. When assembling a reversing circuit, it is extremely important to provide two-way protection against reverse connection: both with the help of a mechanical interlock and with the use of blocking contacts.

The third type of circuit is a launcher, it is used when managing asynchronous motors high power. In the general assembly there are two contactors for each direction of rotation of the drive. In each pair, one contactor is a starting one, through which the motor is connected according to the “star” winding connection scheme, due to which the starting currents are significantly reduced. After some time required to reach the nominal speed, the second contactor is turned on, through which the windings are connected into a "triangle". To implement such a connection scheme, it is required to lay six power wires and one working neutral conductor to the motor, as well as install a turn-on delay relay on the main contactors.

Self-installation of electrical panel in the apartment - good decision. At least, you won’t have to limit the need to develop your own electric / supply scheme for the apartment by the lack of free space in the driveway. And it will definitely not be enough, since most of the houses were built according to outdated projects, and no one imagined that in the future we would have such a variety of household appliances.

Moreover, individual (powerful) devices require their own connection lines, and various protective devices in the form of individual AB, RCD or differential automata. It all comes down to putting together an electrical panel. And not just to equip, but to properly install. How to do this is the topic of the article.

What to consider when installing the shield

On sale there are still shields of the old modification, in which "nests" are mounted for installing the so-called "plugs" (disposable or automatic fuses). There is no fundamental difference, but since the dimensions of modern boxes are somewhat smaller, and the security class is higher, the choice, especially for an apartment, is obvious.

Shields are of two types - built-in and wall-mounted. The former are recommended for hidden wiring, therefore, they are suitable for an apartment scheme. Only the question arises - how to make a niche for such boxing, if there is none? No one will hammer masonry or concrete goods - this is understandable. Therefore, you should purchase a hinged shield. And how to bring wires to it is easy to guess. Available for sale different types connecting products (boxes, pads, adapters), so this problem is from the category of solvable.

Buying an electrical panel on the basis of today is not entirely rational. Any scheme undergoes changes, and there is no guarantee that soon the apartment will not be replenished with a new acquisition in the form of any sample of equipment, for which one more personal line will have to be installed with the installation of additional and AB.

Or the old model will be replaced by a more advanced one with increased power. It is not a fact that the previous protective devices on this line will correspond in their characteristics to the changed parameters of the circuit. Therefore, these products will also have to be changed, and the dimensions of the new ones may turn out to be larger. Will it be possible to place them in an existing apartment electrical panel, given its already dense layout?

But the recommendations found on the Internet to install several spare machines and RCDs in advance, for the future, are very doubtful. What exactly are the products? For what current? Is it worth spending money if it is still unknown whether they are suitable for connecting a new line according to their characteristics.

The installation location of the box is chosen based on the calculation so that it can be freely approached, without any delay. Rarely, but it also happens that the circuit breaker simply does not work, and it has to be turned off manually. By the way, if in order to assemble an electrical panel, the owner, in order to save money, focuses on cheap machines, and even of dubious origin, you need to be prepared for this a priori. Or vice versa - the AB has worked, and after the defect is eliminated on the line, it needs to be turned on again.

Rules for assembling an apartment electrical panel

The introductory (central) automaton is always placed at the top left. If the shield still provides for the placement of an electric / meter, then to the right of it (an example is shown in the photo). It should be understood that only a place is marked under the counter, and it is mounted only after the assembly of the shield is completed and all connections are made. That is, immediately before the . Otherwise, there is a risk of breaking the factory seal. In this form, no one will register the device, even if it does not have any damage. So, you will have to buy a new one.

Lines for connecting sockets and lighting must be "untied". Each has its own machine. If the apartment has powerful household installations, then for one sample - its own, personal AB, connected separately, directly from the central output. In a properly drawn up electrical intra-apartment circuit, this is taken into account.

In the electrical panel, in addition to DIN rails, there must be a grounding block. Boxes are sold in various configurations, often in the form of an empty box, which is assembled from scratch. It is not difficult to visually distinguish the ground bus from mounting strips - by color (yellowish tint of metal), shape (narrow elongated) and the presence of sockets (for connecting wires) and clamping screws. If it is not known according to what scheme the en / supply is organized apartment building, then when assembling the electrical panel, install 2 pads - for "ground" and "zero".

Proper assembly of the box also implies the application of explanatory inscriptions. In the absence of " home master» Any member of the household should easily figure out where which machine is installed. Yes, and your own memory can sometimes fail. Simple marking with alphabetic or numeric characters is the most common option, given that there is little free space in the electrical panel, and by definition it is impossible to apply full-fledged inscriptions. Therefore, it is enough just to draw up a symbol plate and stick it on the inside of the box door. The author did just that. Comfortable and understandable to all family members.

In order to save usable space and reduce the dimensions of the box, in some cases it is advisable to replace the pairs of AB - RCDs with 1 differential machine. About such protective devices.

All protective devices are mounted on DIN rails with the "input" terminals at the top. Accordingly, at the bottom - "exit".

A few of the most common circuit options will help you figure out the correct assembly of an apartment electrical panel.

Correctly assemble the electrical housing shield possible only if developed competent scheme e / wiring, taking into account the complex protection of circuits. Installation work is easy to do on your own. Here the skills of a professional do not play a big role.

The main thing is attentiveness and accuracy. But here it is better to entrust the drawing up of a diagram to a specialist, since not only a drawing will be needed, but also an accurate calculation of all its parameters. If there is no concept in the field of electrical engineering, then you should not take on this work yourself. And even more so, do not copy the layout and connection of shields installed in the apartments of friends, acquaintances, and the like. Nothing good will come of it.

There are certain requirements for a place to install an electrical panel in an apartment. Although this does not directly relate to the topic of the article, it would be useful to recall them.

- Firstly, at a level of at least 150 cm from the floor covering.

- Secondly, the maximum curvature of the base on which the box is attached is 1.50.

- Thirdly, the shield should be placed at the maximum possible removal from engineering communications (gas and water supply). Minimum - 1.8 m.

- In order to make it easier to understand the electrical wiring inside the shield in the future, generally accepted standards should be followed. Wires of a certain color are used for different circuits. Strength (phase) - red, zero - blue (blue), earth - yellow-green.

On a note!

The connection of the power cable to the central machine of the apartment is made after the assembly is completed and the correct installation of the circuit is checked.

see also video assembling the shield for the apartment:

In old houses at the entrance they installed electric meter with a plug as a fuse. More recently, this has satisfied consumers: household appliances there was little and little power. Today, when almost every home has a lot of powerful electrical equipment, a different device for introducing electricity into the house is required.

Electrical panel - what is needed in the house

The installation of an electrical panel solves many problems associated with the safety of using electricity, its quality. New buildings, as a rule, are equipped with them immediately, and in old buildings, it is advisable to install them instead of primitive old ones. The shield will distribute electricity among consumer groups, protect against short circuits and loads exceeding the nominal value.

In a plastic or metal box are installed electrical devices. An electricity meter and a main switch are required. The meter is mounted independently or by employees of the power company. The main switch turns off the electricity consumption in the apartment if necessary, or it works automatically in an emergency. The counter and the input machine, if it is installed in front of the counter, must be sealed.

But this is part of the electrical panel devices. Additional conveniences and safety in a private house are created by circuit breakers. Their role is to protect the circuits of the home network - wiring and household appliances. Each machine serves one group of consumers, and for powerful devices, separate machines are installed. Each circuit breaker is designed for automatic opening or forced opening.

The residual current device contains a differential transformer that compares the balance of the incoming and outgoing current. If it is violated, which happens with an uncontrolled current leakage or when a person gets under voltage, the protection is triggered. The network with the RCD is turned off, and the person does not even have time to feel the electric shock. The protective shutdown is designed for a current that is safe for humans.

In addition to the listed devices, the shield is supplied with tires. The connection of the machines is carried out on the distribution bus in the form of a copper strip - the input contacts are connected on it. A block with terminals for supplying neutral wires is called a zero bus. Grounding is connected to another bus - grounding.

Consumer groups - how to distribute according to the rules

The electricity supplied to the house is correctly distributed among consumers. There are rules, subject to which you can assemble an electrical panel with your own hands:

- 1. All consumers with a power of 2 kW and above are divided into separate groups. For each we put an automatic machine designed for a certain load.

- 2. For washing and dishwasher, air conditioning, other devices with low power need circuit breakers for 16 A. We connect with a cable with a cross section of 2.5 mm2.

- 3. We connect more powerful devices through a 20 A or 32 A automatic machine. We take a larger cable: 4 mm2 or 6 mm2.

- 4. We make lines to sockets separately for each room, using 2.5 mm2. V junction box we make branches to sockets.

- 5. For lighting lines we use a cable of 1.5 mm2, we protect each with a 10 A automatic machine. We run a separate cable.

Cables to powerful electrical appliances should not have branches, but should be laid in a single piece to each consumer separately.

At first glance, the approach to installation with connection of separate cables may seem redundant. In fact, it is the only true one, provides high security, ease of management. In any emergency situation, a group of consumers is automatically turned off, and not the entire network. Finding and fixing a problem with this wiring diagram is much easier.

Electrical panel installation

Schemes of the electrical panel - we make it ourselves

To assemble the electrical panel, a diagram is needed. To compile it, we take into account all the factors and features of consumption electrical energy home:

- how many kilowatts in total is the electricity consumption calculated;

- how much power each group consumes;

- how many separate consumer groups in total;

- where the meter will be installed.

We draw up a diagram in an understandable and convenient way. We indicate the ratings of the devices, the cable cross-section, the wiring to consumers. Below is an example of the internal filling of the shield and the wiring for a single-phase network.

For a three-phase mains voltage, there are no big differences in the circuit. A different principle of distribution of consumers is applied: separate groups are connected to separate phases. It is important to balance the load between phases.

Accessories - which shield and modules to choose

Frame switchboard made of metal or plastic, fixed on the wall or recessed into it. With hidden wiring, a distribution panel hidden in a wall niche is more suitable. The external shield can be installed indoors or outdoors. The question of choice is important: a very cheap plastic case quickly becomes unusable. It is better to buy a box that has removable walls, in which DIN rails can be easily removed or pushed back. In size it is better to have some stock inner space.

The initial element of any scheme is an introductory machine that turns off the flow of electricity to the house. Its ratings depend on the total power consumed by the house. By the Decree of the Government of the Russian Federation, it is determined that grid organizations carry out a standard connection of 380 V power supply at 15 kW. If you need more, connect for an additional fee.

- rated current;

- the current at which the machines operate;

- their speed of operation.

Automatic machines are installed in each circuit separately. It is important to calculate their parameters: with insufficient power, false alarms will constantly occur. At low power, they will not be able to fulfill their purpose - to protect against overload. The machines are equipped with a device for the time of operation. Downstream should be set with a shorter trip time so that it occurs on the output line.

With a rated current higher than the total current of the automatic devices subordinate to it. Then the machines will turn off earlier, protecting the RCD from damage.

Internal filling - layout of modular devices

The equipment mounted in the shield is manufactured according to standard unified dimensions. For fastening, a DIN rail is used - a metal profile. One place occupied by a single-pole circuit breaker is called a module. To calculate how much space is needed in the shield, you should know that a two-pole AB is 2 modules, a three-pole is three. A single-phase RCD occupies 2 modules, a three-phase - 4. One terminal block - one module, a meter, depending on the modification, - 6-8 modules.

It is carried out on the table, which is much more convenient than on the wall. But you must first install the mount for the shield when it is not yet filled with modules. Implementation circuit diagram can be carried out in several ways: linear or group. Regardless of the method, the introductory machine is always the first. According to the linear principle, all RCDs are located further, followed by automata. The accommodation is simple, but the fault is hard to find. According to the second method, the devices are placed in groups: first the RCD, then the automata of its group.

Installation rules must be observed:

- connections inside the shield are made with a wire that is the same in cross section as the input;

- the entrance is at the top, the exit is at the bottom;

- it is forbidden to clamp a stranded wire without lugs NShVI;

- to clamp different conductors in one terminal, use lugs for two wires.

Let's start assembling. We arrange the modules according to the selected scheme on the DIN rail, fix them with clamps. To make it easier to work, in addition to the scheme, we draw up a plan for the location of devices. Then we connect them together with wires. We clean the ends, if the wires are stranded, we insert them into the NVSHI lugs of a suitable section. We crimp the tips with KBT press tongs, which are not very expensive in cost. It is this tool that will securely fix the conductors in the lugs.

The use of special tires (combs) will greatly facilitate the disconnection of the electrical panel. They are equipped with flat contacts (pins), which are inserted into the contacts of automation, providing reliable connection. Manufacturers of automatic devices produce combs that are suitable in size for these modules, they may not be suitable for others due to differences in pitch.

You should buy all circuit breakers, differential automata, RCDs, tires from the same manufacturer, which will greatly facilitate installation, the shield will look beautiful and compact.

Cable connection - entry and termination inside the shield

Proper cable entry greatly simplifies installation and enables optimal organization of the interior space. You should buy shields that have technological holes for input, otherwise you will have to cut or drill. In good shields there are plugs that we remove and start the cable. We connect to the introductory machine, fix it with a plastic clamp. We mark all cables immediately.

Surface insulation at the input is not needed, therefore, carefully, so as not to damage the insulation of the conductors, remove it. It is more convenient to work with individual wires than with a rigid cable. We distribute all the wiring in the shield in bundles: separately phase (L), zero workers (N) and protective zero (PE). We want them to overlap as little as possible. We pre-mark the ends, tighten with clamps.

Leading the cable inside the shield, leave it a length that is twice the height. This is done as follows: they stretched the cable to the connection point, stretched it again to the inlet and cut it off. This is not superfluous at all: the wiring follows its own path, and not the shortest path. When you have to stretch them to reach your destination or build up, this is bad. So saving a dozen centimeters is not worth it.

Commissioning and operation of the electrical panel

After installation is completed, turn off all devices in the shield. We load all sockets. We apply voltage, check the presence at the input, the correct phase and zero. One by one with the "Test" button, we check the RCD and difavtomat. We check the voltage at the input of the machines, turn on one at a time and check the output voltage. We turn on powerful devices, monitor the condition of the shield: there should be no sparking, smoking, heating. Check sockets and lighting.

The electrical panel should be inspected periodically. Be sure to open it in a month and tighten all the contacts. In the future, monthly check the operation of the RCD. If the installation is carried out in compliance with the recommendations of experts, thoughtfully and without haste, the equipment will serve for a long time and reliably.

Mass construction housing stock and the ongoing reconstruction of old buildings are pushing apartment owners to the need to independently understand the technologies for performing electrical work in their premises. This allows you to create an individual electrical system that meets the specific needs of the owner, and not use typical scheme designed for the average consumer.

How to choose the location of the electrical panel

In order to properly assemble the electrical panel in a newly built apartment, it is necessary to draw up before starting work, in which it is necessary to provide in detail the implementation of your needs inside each room, consider the location of lamps and switches for them, the number of sockets for portable and stationary electrical appliances.

At the same time with electrical wires often it is necessary to lay pipelines for water supply, heating, telephone lines, antenna cables, a computer network, alarms and other low-current circuits. Route optimization for all these systems is part of the project development.

The electrical panel is the place where the cable coming from the power supply organization is connected to the electric meter for further distribution of electricity to the consumers of the apartment through switching machines.

The task of the project is to determine the most suitable location for the introductory electrical panel. V Lately it is customary to install it not on the landing, as they did in the last century, but inside the apartment. This eliminates the access of unauthorized persons to the equipment and creates certain conveniences.

Usually, the location of the shield is chosen in the corridor near the front door at the height of the face level because it is so convenient for residents and to turn off unnecessary consumers when leaving the apartment. And when performing installation, the length of the supply cable is reduced.

When choosing the location of the shield, the owners of a cottage and a private house should take into account the safe organization of the input device into the building, the design of a branch from an overhead power line or cable line, coordinate their device with the power supply organization.

How to choose the design of the electrical panel

In residential buildings, two types of electrical wiring are used:

external, laid on the surface of the walls;

internal, hidden in strobes and cavities.

Electrical panels are produced under them, which can simply be attached to outside walls or mount inside it, making an appropriate recess.

The shield box material is designed for a long service life. They may be:

durable plastic.

External and internal decorative trim, made in various shades of color, allows you to make quality choice for the design of any room.

Responsible devices are located inside the shield. Access to them by unauthorized people and children should be limited by closing the door with a lock, the key to which must be kept in a separate place. To monitor the meter readings, it is enough to have a window on the door.

Almost most modern shields are produced for convenient and reliable placement of electrical devices on. Such structures should be used. They significantly save space and make it easy to dismantle a faulty device.

To fix the machine, it is enough to attach it with the rear groove to the rail, pull off the mounting latch with a screwdriver, slightly press on the case and release the latch. Removal is carried out in reverse order.

How to do interior installation

The sore point of most unprofessionally assembled circuits is a continuous tangle of mixed wires, which is difficult to understand even good specialists. Internal installation must be thought out in advance.

To do this, it is desirable to lead the input cable from its side from above or from the side, and the outgoing cables from the opposite side. This technique also saves cable length.

When installing, it is advisable to adhere to, given as an example for the input cable. When this is not possible, the ends of the strands are signed with a non-fading marker or dichloroethane-based black ink.

Tires for working and protective zero are located on the side, providing free access to them. The use of special designs of terminal blocks for busbars in the housing facilitates installation, makes it more understandable.

When a differential machine is used instead of an RCD with a circuit breaker, the working zero after it is output directly to the load cable, and not to the busbar. Otherwise, the difavtomat operation algorithm will be changed, the circuit will not work correctly.

The design of the circuit breakers requires their installation in a vertical position with input contacts on top. With a different placement, they work, but their resource is reduced. Only well-known brands of companies such as Siemens or Legrand allow you to arbitrarily orient expensive models of their products.

The connection of incoming wires to the machines is carried out on the upper contacts, and outgoing circuits - on the lower ones. This is accepted by the etiquette of electricians: it is easier to search for emerging faults within the circuit.

In addition, in the designs of most automata, fixed contacts are located on top. Arcing devices and a movable contact part are placed near them. The passage of current from the bottom up can cause power losses.

In any case, the main principle of installation should be the complete uniformity of the ways of connecting conductors on all elements inside the shield body.

Only two conductors are allowed per terminal. A larger amount can weaken the electrical contact over time, so it is prohibited by the rules.

To connect machines to each other, many electricians make jumpers. Aesthetic appearance and reliable connection provide electric combs, which are produced by manufacturers of circuit breakers. They speed up installation, save space for wires.

All work inside the shield is carried out according to the approved scheme electrical connections, a copy of which should always be at hand. It is often convenient to stick it on the door from the inside. In this case, all wiring connections of the circuit are transferred by marking to the operating equipment.

Each element of a working circuit must be signed so that its purpose is clear even at a cursory glance. To do this, you can type text on a computer and print small explanatory inscriptions on a printer.

When there is no place for such labels, then a bright digital designation is applied to all equipment, and an explanatory table with detailed decoding is glued to the door necessary information. It is convenient to store such a sheet near the electrical panel.

Detailed documentation, clear labeling and clear installation increase the reliability of electrical equipment operation, give the electrical panel an aesthetic appearance, and ensure quick troubleshooting.

After graduation installation work all installed equipment must be inspected, electrical connections and fastening elements are pressed, installation is carried out correctly and fully assembled chains are measured. Only after this is it possible to test the inclusion under load and testing in operation.

During operation, it is necessary to carry out periodic preventive inspections and check the condition of the threaded connections in the terminals. This will guarantee reliable operation for a long time.