Such a piece of furniture as a kitchen (or as it is also called a dining) table is the main component of the kitchen interior. Its shape, size must correspond to the size of the room so that all family members can freely accommodate behind it. It is also important that the kitchen table does not interfere with free passage.

Sliding dining kitchen table-transformer

There is currently a wide selection in stores. kitchen furniture, of various shapes and sizes, made from a variety of different materials. There are tables of both Russian and foreign production on the market.

The original round dining table with chairs in the interior of the kitchen

Choosing a table for the kitchen big size, you have to make a choice - do you like it when there is a lot of free space, or is it important for you that the furniture is comfortable, roomy. If you can’t decide on a suitable table for the kitchen, try making it yourself. Those who have a certain skill can do it quite well.

Wooden round table with a four-post structure, handmade

DIY folding table for a small kitchen

Many men who like to make their own hands can save a lot on the family budget, because finished goods are not cheap. Accordingly, you independently select the material for the manufacture of a high-quality dining table and the necessary fastening. By demonstrating design skills, you will assemble an original piece of furniture that is ideally suited to the kitchen interior.

Folding table in the kitchen, which does not take up extra space

Don't think it's difficult task. It does not take much time to assemble a dining table - just a few days. A little more difficult to make a countertop. It is better to first consult with friends involved in such cases, or read information on the Internet.

A table with shelves and a reclining tabletop with your own hands

Assembling the table with your own hands, you will create a unique thing, bring to life a long-standing idea. Maybe with your light hand, organize the production of kitchen tables, and it will grow into a profitable business.

Deciding on design and construction

Round wooden table with handmade painting

Square wooden table for the dining area

The design and shape of the dining table can be very diverse. Designers, using fantasy, bring to life the most unusual ideas.

Dinner table sliding oval with chrome legs

Consider the design of this piece of furniture.

| Round table | It has smooth lines, as if uniting those who sit at such a table. It has several legs or one large one. It is comfortable to sit behind it, you will not have an association associated with the place of work or study. There is one drawback - it cannot be tightly placed against the wall. |

| Oval | Great option for owners large kitchen, which is divided into working and dining areas. Perfect choice for big family, strong enough |

| Square | The embodiment of rigor, but at the same time it is simple and multifunctional. Suitable for small spaces, save space well |

| Rectangular | Widespread variant. Behind it can accommodate many people. It is placed as you like - in the center, against the wall, near the window |

| Triangular | Such a table is quite rare in the kitchen. It is used as an unusual decoration element, for example, as a coffee table. |

Wooden kitchen furniture set: rectangular table, bench and corner

Dining corner table from glass

Owners of a small kitchen prefer to use a book table or a sliding table. Since in the assembled state they save a lot of space. Other forms of tables are few where you can see. If you prefer products of the original form, it is better to make them to order.

Large classic solid wood dining table

The kitchen table, like any other furniture, is selected for a certain style of interior. For example, an ordinary wooden table is suitable for classics. High-tech is characterized by right angles and lines, so they choose tables made of plastic, metal, glass, with an emphasis on white and gray shades. For modern style is used unusual furniture with twisted lines. Eco-style means products made from natural materials.

Original high-tech folding dining table

Designer advice. Whichever table you choose, the main thing is that it matches the interior and complements the overall look.

Necessary materials

Dining table materials may vary. Here are the most used ones:

- chipboard;

- board glued, edged;

- beam.

You can combine them if you wish. You will also need: corners, hinges (for folding models), rollers, confirmations, corner fasteners, eccentric bolts, lining legs, tape for edging, plastic profile for countertops, plugs.

Required Tools

You can not do without a standard set of tools:

- jigsaw;

- drill;

- hacksaw;

- screwdriver;

- drill;

- screwdrivers;

- electric planer;

- grinding machine;

- hexagons;

- building hair dryer (can be replaced with an iron);

- tape measure (ruler), pencil.

In the manufacture of complex models, you can not do without additional tools.

Manufacturing process: step by step instructions

We will make a tabletop from wooden boards

How to make a kitchen table with your own hands? Consider this on the example of an ordinary dining table. First of all, we prepare the tools and materials that will be needed for the job.

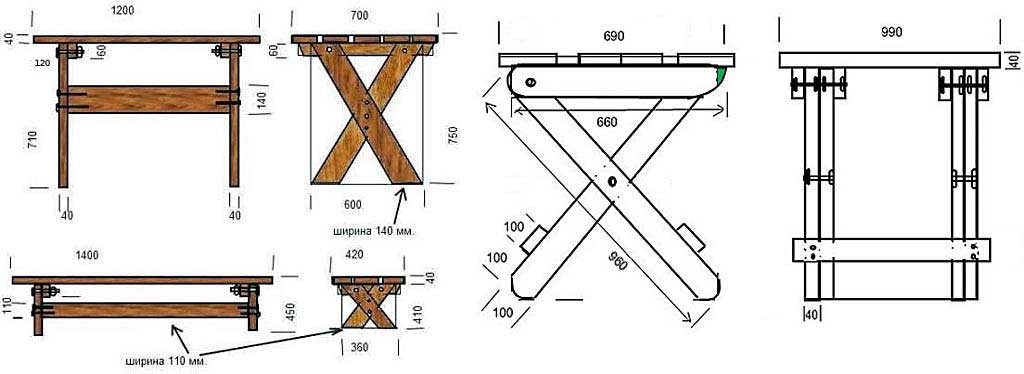

Scheme of the future dining table with dimensions

Then we mark up the furniture elements. We start with the tabletop, as this is the largest part of the table. It can be rectangular, round, square or oval in shape. If you are planning to make a table of an unusual shape, mark up according to the sketches.

We grind the boards with a planer, carefully process the edges so that the boards fit as tightly as possible to each other

We connect the boards with glue and dowels, remove excess glue on the surface and grind it

Then we apply a drawing of the side racks to the material - these will be the legs of the future table. Most often in shape they imitate a chess piece. If you want, you can make other shapes as you like. The main thing is that the design is stable.

We fasten the legs and make the base for the tabletop

Then we mark the upper and lower crossbars, which will connect the racks and thereby ensure the reliability of the structure. Remember that the bottom bar is always almost twice as wide as the top bar. Its form is varied. Usually the legs are located from the edge of the table surface at a distance of 15-20 cm.

At the next stage of work, we cut out the elements. We place the material on the table. Cut out the tabletop using a jigsaw. To avoid the appearance of chips, we put plywood under the bottom. Cut out the rest of the pieces in the same way. Do not allow material to sag. Because of this, the tool may break or break off the cut element. At the end of cutting the edges of the parts, we grind with a special machine or go through them with sandpaper.

We fasten the legs to the long crossbars and drill holes in them in order to install the countertop later.

Using tape to trim the edges and plastic profile, we produce trimming. First we put the profile on the edge of the surface. In the place of the angular bend, the profile must be heated with a hairdryer and then rotated. For high-quality fastening, use universal glue.

After the glue in the frame dries, you can proceed to install the countertop on the frame

Then we trim the legs and crossbars using tape to decorate the edge. Before this, we prepare the surface, cleaning it from dirt and grease. With a hot iron, press the tape to the edge and glue it. Cut off the excess with a sharp knife. The resulting irregularities are carefully removed with sandpaper. In the same way, we process the edges of the remaining elements.

If you want to make the table longer and wider, then you need to strengthen it with two additional cross bars

We assemble the table in the following order. Using confirmations, we connect the legs with the crossbars, positioning the top of them so as to prevent the countertop from deflecting. We fix the lower one at a height of 20-25 cm from the floor.

The finished assembled table remains only to be varnished or stained or painted, pre-primed

We lay the countertop on the finished base, fix it on the corners. We attach the legs-pads to the racks. We decorate furniture screws with plugs. Everything, the dinner table is ready!

Ready-made universal option - the table top and legs are stained

You can paint the legs white, and stain the countertop to get an unusual design.

This piece of furniture is one of the most versatile in use. The table can be a dining table, household table, installed in a living room, on a veranda, territory, in a workshop, and so on. In a word, it is impossible to do without it. But purchased products do not suit many for a number of parameters - size, design features, shape, or for another reason.

Given that the tree is relatively easy to cut, grind, make a table out of it according to your own drawing, with your own hands for a good owner is not a problem. Yes, and it will be much cheaper. Plus - satisfaction from such work.

room

This is ideally an extension, a barn, an empty garage, although a small area under a canopy is also suitable. To work with a tree on a site, in the open air, means to be completely dependent on the vagaries of the weather. If there are “square meters” suitable for making furniture, then you should worry about high-quality ventilation in advance. Natural is sometimes not enough (besides, it depends on the change in wind direction and pressure), and an exhaust hood is installed.

Arguments that if you use protective equipment, then you can work in a closed space, do not stand up to criticism. Wood dust will immediately settle on everything, including the sample with which some actions are performed. Neither an accurate cut along the line, nor a high-quality surface treatment of wood (not to mention the impregnation and finish coating with a paint and varnish composition) can not be obtained.

It is impossible not to take into account the fact that many preparations used for wood processing contain toxic components. For example, varnishes, paints, impregnations, if they are not natural, then harmful fumes are guaranteed.

Instruments

Their set depends on the extent to which it is planned to "ennoble" simple design from wood, what shape to give it and a number of other nuances. If the master does not pretend to grace wooden table, does not aim to achieve its originality, then the usual carpentry set is quite enough.

For more “fine” work in the process of making a table of unusual shapes, external design, special devices will be needed.

El / jigsaw. With a conventional saw, it will not work to make an inclined vertical cut, accurately maintaining the angle. The canvas will “play”, and therefore the quality of the work will be extremely low. The electric jigsaw is universal in application, besides it gives high accuracy in cutting wood or cuts in it.

Many of the listed fixtures can be rented if furniture making is not a hobby, but a necessity.

Impregnation and other compounds

Rotting protection:

- Working off engine oil is an effective, moreover, free tool. But not for dinner tables.

- Linseed oil. A natural and effective product that penetrates deep into the wood structure and protects it from mold and mildew. Minus - high cost. But if the table is intended for eating - a great option. The drug has no color, therefore, after processing the lumber, it does not leave any traces in the form of darkening, stains, streaks, unlike mining.

- The emulsion is water-polymer. It is characterized by duration of action and safety for health.

- Acrylic varnishes. They practically supplanted their predecessors of the "NC" category, as they are harmless and in many respects better lineups which are diluted with solvents.

- PVA, bone glue and a number of others. More detailed information about carpentry compositions -.

To decorate a tree:

- Colorless varnishes are used not only to protect the material from moisture. With their help, you can save the texture of the tree, shade it.

- Wood stains.

- Varnishes with a coloring effect (toning).

- Paints (but only for wood!).

- Putties.

Using a colorless varnish and pigments, you can make a coloring composition, and of any shade. It is enough just to correctly determine the proportion of components. This is easy to do by experimenting with mixing and applying a sample to a rejected board. This will allow you to choose an acceptable tone. More than expedient, since it is not always possible to buy exactly what you need on the market.

Fasteners

All tips for assembling a wooden table with nails (the argument is simple, fast and cheap) are best ignored. The reasons are as follows:

- A nail easily pricks a dry tree (and this is exactly what is taken; more on that below).

- Correctly directing his leg (strictly vertically) is quite difficult. In some cases, it is even more difficult to redo your oversight.

- A tree, even the most protected from rot, eventually succumbs to it. The maintainability of a table knocked down with nails is extremely low. Practice shows that it is rarely possible to remove such fasteners without damaging adjacent structural parts. As a result, instead of the planned replacement of one element, 2 - 3 will have to be changed.

- When assembling a wooden table, if one glue is not enough, you should use only self-tapping screws.

- Sometimes its individual parts (at the joints) require reinforcement. It is not advisable to strengthen the strength with a hardware with a thicker and longer leg. The reason is the same - the probability of splitting the tree. For these purposes, metal strips, brackets, corners are used.

Features of the choice of wood

Someone focuses on the cost of lumber, another is important for the resistance of the tree to decay, for the third - its texture. What can you recommend to a novice furniture maker? Do not use for the table, unless it is intended to be installed somewhere in the back room or garage, the same type of wood. This is exactly what many novice "craftsmen" do, picking up the same type of boards and bars from what is left of the construction or repair and gathering dust in the barn.

When making a wooden table for living quarters, verandas, and so on, you need to take into account the properties of individual species. Naturally, if there is not enough experience in assembling furniture, you should pay attention to cheaper wood. The first table (chair, stool) in life is just a kind of training in manufacturing, gaining experience.

Tabletop. Here in the first place - strength and minimal absorption of moisture. It is on this part of the table that something is constantly spilled. Optimal choice- pine, larch, oak (although the latter is more expensive). Thickness - at least 3 cm.If the dimensions of the countertop are small, then wood-based slab products (OSV and the like) can be used. But only with lamination to prevent swelling of the material when liquid enters the surface of the table. For example, LDSP.

In the furniture industry, low-grade lumber is not used. This is not economically feasible, since pre-treatment of wood increases the duration of the production cycle. But in the manufacture of something, wood of lower grades, substandard - just right. The same pallets left after using stacks of foam blocks or bricks.

And not just because it's free or relatively cheap. Many of the disadvantages of such wood with a competent approach can be turned into pluses. For example, after coating with a colorless varnish, the countertop acquires a unique original look.

The main thing is that the boards do not have obvious defects in the form of rot, cracks, falling knots and wormholes.

If pine is chosen for the countertop (this also applies to many other conifers), then you need to pay attention to the location of the annual rings. These arcs are called humpbacks. The cuts of the boards show how they are oriented, and this is taken into account in the process of laying them in a row. Samples obtained by the tangential sawing method are arranged in alternation (top top down, the next one up); radial cutting - the same way (with arcs in the same direction). The nuance is insignificant, but it is the observance of this recommendation that eliminates the risk of warping and splitting of the boards.

For furniture, if you think about its durability, you should take only dry lumber. During the drying of the wood, it will deform; this is a natural process, and its consequences in the form of twisting, warping, bending are inevitable. Such a table will quickly begin to warp, and you will have to deal with its repair. And here you need to decide whether to purchase high-dry wood or rid it of moisture yourself. The first option is simpler, but such a tree is more expensive. The second will cost less, but there are a number of purely technical difficulties.

- First, it is necessary to ensure stable temperature regime in the storage area. Changes in its value will lead to uneven evaporation of moisture, which will negatively affect the strength of the tree.

- Secondly, good ventilation must be organized.

- Thirdly, and, perhaps, this is the most unpleasant moment - you will have to wait, up to about six months, depending on the initial moisture content of the tree. But this is not a guarantee that the result will be expected; Even this takes practice.

This once again confirms the idea that when starting to make wood furniture for the first time, you should focus on the simplest table for household needs from cheap lumber, without pretensions to its sophistication and originality of design. For example, for a barn, garage and the like.

Variants and schemes of wooden tables

It should be noted right away that any work related to the design and self-assembly is a creative process. There are no stereotypes in this business, so you can only take the model you like as a basis, and everything else - linear parameters, shape, manufacturing specifics - depends on the purpose of the product and your own imagination. Here are just a few examples of what wooden tables can be. For example, for summer cottages, small utility rooms, it is worth choosing structures whose geometry can be easily changed - folding, hiking, hanging, garden, level, and so on.

Tables that are supposed to be used for meals, games, as coffee tables for installation in living rooms intended purpose, are made stationary, that is, of unchanging size. These assemblies are more “solid”, since all articulated parts are fixed rigidly; no articulated joints.

Features of the assembly of wooden tables

If a person undertakes to make something, then he knows how to use the tool, read the drawings and work with lumber. Such home master learning the basics of carpentry is not necessary. But a number of nuances in the manufacture of a wooden table will be useful to note. These notes will only help in the process of work.

Let's start with the types of connections. There are quite a few of them, but for a table that is assembled with your own hands, the following are quite enough.

On dowels

In this case, the parts are fastened by landing on the adhesive composition (Fig. 1 - 3).

The nuance is that for the manufacture of "cylinders" that are inserted into pre-drilled "channels", a tree of a denser structure is taken than the elements of the table. This is what ensures the strength of the connections. Before installing them, chamfers are removed from the edges of the dowels and holes.

These round sticks are commercially available, in any furniture showroom, several sizes. To grind them, even with a carpentry machine, is a waste of time. It is not recommended to purchase plastic dowels for the table; they are used for collapsible connections. For example, frame furniture (walls, multi-level racks, etc.).

Nails should not be used to fix table elements (Fig. 4). Metal and wood differ in the degree of thermal expansion. Such a connection will not last long - a “shat” will begin, especially if the table is intended for installation on the territory or in an unheated room.

On the tsargs

It is advisable to make such connections if the table has to be either periodically disassembled, or without it it cannot be moved through the doorway. Although not all kings involve the dismantling of the structure. The most practiced options are shown in the figures.

Bolted

Such connections are mainly used for garden or outbuilding furniture; for utility tables. An example is shown in the figure.

The nuance of working with fasteners

In order for the self-tapping screw to be easily screwed in and “go” in the right direction, a hole is first made at the point of its installation with a drill, with a diameter slightly smaller than the fastener leg. The main thing is to maintain the coincidence of the center lines, that is, to prevent skew. In this case, for the "landing" of the self-tapping screw, you can do without a screwdriver.

Features of wood processing

Everyone knows that a planer is used first, an abrasive with a large grain, and then a fine one. But sometimes it turns out that the last stage, grinding, has to be done repeatedly. Here much depends on the type of wood and the degree of its drying. After applying the first layer of varnish, the villi may “stand up”. Nothing wrong with that. You should wait for the workpiece to dry and repeat its processing with an abrasive. The work is painstaking and takes time. But it is by this technique that you can bring the "problem" wood to the ideal "smoothness".

To eliminate the risk of injury to a person, all edges and corners of the table should be slightly rounded.

Features of the exterior

- Minor defects in the form of cracks, chips are eliminated with a putty composition.

- After sanding, all wood dust must be removed. In this case, an ordinary household vacuum cleaner with an appropriate nozzle will help out. After such cleaning, it is recommended to wipe the entire table with a slightly damp cloth, let it dry and repeat the cleaning of the remaining dust. After that, you can safely proceed to applying stain or varnish - there will be no “pellets” on the tree.

- You can give originality to the table not only with curly cutouts, unusual shape countertops or legs, a combination of textures of different species and so on. One of the good options is art painting.

And finally. Work on the independent manufacture of something from wood (the same table) is just the initial stage in mastering the skill of the “assembly designer”. Having worked out the technologies, techniques on wood, having acquired the necessary skills, it is enough just to switch to other materials - metal, plastic, glass. So the benefits of a wooden table made according to even the simplest drawing (apart from the pleasure of working and saving money) are obvious - not wasted time.

An integral attribute of any home is a table. Despite the fact that the variety of forms and materials of execution of this piece of furniture can amaze even the most demanding and sophisticated buyers, many amateur furniture makers try to make a table with their own hands. There is nothing complicated in this, because the design of the table is not much more complicated than an ordinary stool. Armed with a saw, drill, hammer and other tools, you will be able to assemble such a product in just half a day, and it will look no worse than the purchased one. One of the main advantages handmade of this furniture lies in the possibility of creative self-expression. In addition, a do-it-yourself table can become a central element of any interior.

It's no secret that the main function of the table is to organize a place for dining and receiving guests. In addition, it often serves as a place for family pastime, during which you can enjoy various entertainments: playing cards, monopoly, lotto, dominoes, etc. In addition to significant savings and demonstrating your carpentry skills to others, making a table with your own hands provides a person with an excellent opportunity create a unique little thing that is ideal in all respects: shape, size, material and reliability. Following the instructions and recommendations of professionals, you will see from your own experience that this piece of furniture is quite capable of being made by yourself at home.

Today, various building materials are used for the production of tables: metal, glass, plastic, stone, but furniture is often made from such high-quality material as wood. For creating wooden table soft (spruce, pine, cedar, fir), hard (birch, walnut, oak, maple, ash) or very hard (dogwood, yew) wood species that have good resistance to decay and mechanical stress can be used with your own hands.

Walnut has the most valuable qualities for furniture - it combines high hardness and excellent viscosity. If you are new to carpentry, it is recommended to give preference to furniture made of pine, birch and oak. Deciding to make a pine original table with your own hands, you can use cheap knotted boards, but they should not have falling knots, cracks, stains and traces of rot.

Before proceeding with the analysis of specific points and recommendations that will help you make a table with your own hands, it is important to decide on the design of the desired product. Due to the perfect combination of naturalness and environmental friendliness of wood with a country concept, a homemade wooden table will become great option garden furniture. A small do-it-yourself table made of wood, as if deliberately aged, will also fit well into the design of a city apartment made in Scandinavian or Provence style. It is noteworthy that, in terms of the complexity of the work, this piece of furniture for most craftsmen is almost like a homemade made of wood, since a homemade table is assembled very easily. This fascinating process is reminiscent of assembling a constructor.

On the virtues of wood

Whatever form you choose for your wooden table, it will always be durable, safe and environmentally friendly. The main advantages of wood furniture are that it is not afraid of loads, sudden changes in temperature, external influences and various scratches. The main advantages of wood include:

- environmental friendliness;

- ease of processing;

- aesthetic appeal;

- availability;

- high specific strength;

- resistance to chemically aggressive substances;

- the ability to create the most acceptable microclimate for humans;

- low thermal conductivity;

- small weight;

- low density with high strength.

All these qualities make wood a sufficiently durable and strong material capable of resisting destruction under mechanical stress. For this reason, it is often used to make various kinds and forms of tables, for a dining table, country, office, etc.

In the process of assembling any furniture, it is necessary to adhere to certain recommendations that will achieve the maximum quality of the finished product. First of all, this refers to the choice of wood. Thanks to the huge number of different protective equipment offered by modern hardware stores, you can make a wooden table with your own hands from pine boards. Despite the cheapness of this material, proper processing will allow the table to delight you for many years.

When answering the question of how to make a wooden table, it is important to note that at the first stage, a drawing should be drawn up with all the marked dimensions, and a diagram with an approximate cutting of the parts that will be involved in the assembly. For a small number of people, it is best to build a simple table of standard sizes, and if you want to make a beautiful and unusual table that will become your pride, you can give preference to the hinged version. When we make a table, it is important to consider that the optimal width of a piece of furniture is 80-100 cm. To determine its length, it is necessary to take into account the convenience of seating household members and guests when you get together.

It is very important to follow the sequence of actions, otherwise the table made from improvised materials may turn out to be unstable. 2 conditions that without fail must be observed in the manufacture of this furniture product, are:

Leg stability. Try adding stiffeners, supports, and bridging to the legs to improve the table's stability.

Smooth tabletop surface. This can be achieved by observing the exact dimensions of the length of the legs, the lower surfaces of which must be well cut. To check, use the level - it will show whether the table is in the correct plane.

When choosing the location of the kitchen table, it is important to consider that when you install an object with a long side to the wall, you reduce its capacity by as much as 40%. In addition, it is not recommended to install this furniture near the stove and under the air conditioner.

Product assembly process

So, how to make a table out of wood? Construction of a wooden rectangular table represented by the following components:

- countertop;

- jumpers;

- underframe;

- legs.

Particular attention should be paid to the countertop. Very often, oak or walnut is chosen to create it. This is due to the fact that this element must be made of hardwood, especially when it comes to outdoor tables for a country house. Plywood is an alternative. Having made a high-quality surface treatment from plywood, you will make it resistant to potent chemicals and external influences.

It is important to remember that moisture that has fallen on such a surface will cause the material to swell and deteriorate. To avoid such consequences, wood must be protected: varnished, painted or waxed. To make the countertop, you will need wooden boards, as well as some carpentry tools: a saw, an electric jigsaw, an electric drill, a grinder, a tape measure and a ruler.

Step-by-step instruction

When all the tools and materials are prepared, you can begin to assemble the table with your own hands from wood. In this case, the corresponding instruction will help you:

- First of all, hardwood boards should be cut, the size and number of which are affected by the length and width of the structure. It is advisable to sand them immediately, because on individual elements this is much easier to do. In addition, it is necessary to treat the wood with a protective compound to provide more reliable protection.

- Take 2 boards that are at least 5 cm thick (you can choose the length and width of your choice) and connect their bottom parts using 2 or 3 wide boards of the same breed (minimum thickness is 20 cm). The connection must be made with wood screws, which are 1 cm less than the total length of the boards. Tighten them from the inside with 2-3 screws.

- After connecting all the boards, take a planer and walk it along the contour and the outside of the surface to align all the ledges.

- The next step is to sand the surface.

- Next, the underframe and legs are made, which will be equipped with a homemade table. To do this, use the same material as in the manufacture of countertops (5 cm thick). You can achieve beauty and symmetry by cutting the board at the joints by half the thickness, that is, by 2.5 cm. Attach the legs to the table top and drill holes in the bar under it to connect all the knots.

- Connect the legs to each other using a special jumper.

- Finish and paint them, or varnish all components except outside countertops.

- Attach the table top to the legs. Use metal corners and screws to give the structure strength.

- Paint the table top. For this purpose, stain and paint can be used. If you wish, apply any drawing you like.

By adhering to easy rules, you can not only assemble a table that will last a long time, but also moderately decorate it just like a work of art.

The nuances that you should be aware of to create a quality wooden table

Continuing the conversation about how to make a table from improvised materials, it is important to clarify that the number of legs that will hold a wooden table with your own hands should be determined by the size, weight and shape of the piece of furniture. A small wooden table with your own hands can be equipped with 2 such legs, and for the middle version it is better to make 3-4 legs.

Often, the middle structure is equipped with 4 legs, and wood is used as materials for their implementation, which is resistant to various damages and loads from the countertop. If you want to use one leg that will hold the entire structure of the table in an upright position, you will need to take care of its cruciform strapping. In the case of 2 legs, they must be placed on the sides of the product. It is important to take care of the aesthetic appeal of the legs - they must be in harmony with the tabletop. It is a good idea to use balusters, which will allow you to make your table even more spectacular and attractive. This applies to any similar products - both street and home, intended for food.

To make a table with your own hands, it is important to know that the frame on which the tabletop is installed consists of 2 racks connected by a drawstring and 2 legs. First, you need to cut out the upper and lower jumpers, and then bring the edges into proper shape by planing and leveling them.

The next stage involves making a selection in the supports and removing the bevels on the lintels, on which nests for installing the racks will subsequently be made. Approach with all responsibility the choice of the form of the table, since the appearance of the entire room depends on it. The fact is that in most cases the surface geometry contributes to a sharp change general view the whole space. The most popular are countertops with right angles, which fit perfectly into both square and rectangular kitchens.

Conclusion

As you can see, wooden tables can be of various configurations. You only need to choose the most suitable solution that will successfully fit into the design of your interior, and assemble it. The main thing is not to rush and do everything as carefully as possible. Remember that desire alone is not enough, you still need to make efforts and show ingenuity in order to achieve the desired result. In most cases, everything depends on financial capabilities and ingenuity, so go for it and may success be with you!

We will send the material to you by e-mail

Not everyone likes to buy ready-made products for home use. The soul of some people requires creative and practical self-realization. The editors of the online magazine, the site invites those who wish to learn how to make a wooden table with their own hands, what is required for this, and whether there are pitfalls in such work.

A beautiful piece of wood for the kitchen or living room, made with love

Professional carpenters are unlikely to need our step by step recommendations, but for beginners, advice will come in handy. To begin with, consider what products you can make with your own hands from wood.

Of course, the more skills a person has, the more complex the model he can make. But in order to build a table with your own hands from wood, there are ready-made drawings and photos to help beginners.

How to choose material for self-production of a wooden table for home and garden

What to make a dining table with your own hands? The best is wood. The most malleable for the newly-minted master will be pine. Poplar products will look more solemn. For the street, you can take mahogany.

If you want an option for the home and easier, then you should consider laminated chipboard with an optimal thickness of 25-35 mm. On the countertop, you can take wooden boards, birch plywood with a thickness of 35 mm. Legs can be made of metal or wooden beam(about 50 mm thick).

In order not to be mistaken with the amount of material, a preliminary drawing of the future design is made with exactly the specified dimensions.

Advice! Suitable product height varies between 750-800 mm.

Related article:

DIY furniture made of wood: for garden, children's room, kitchen, sauna, garden, arbor; how to restore pieces of furniture, useful tips and recommendations from experts - read our publication.

What tools are needed to make a wooden table with your own hands

It doesn’t matter what shape the future table will be: a certain set of tools is required to work with wood. You can’t do without a jigsaw, and it will be much easier to work with electric model. To fix all structural elements, either a drill with a multi-stage drill for holes, or confirmations is used. To grind the product to perfection, you need either a special nozzle for a drill.

For greater fastening strength, carpentry glue is included in the tools.

How to make a wooden table with your own hands - step by step instructions

We have selected four types of structures that you can make on your own, even with a minimum of carpentry skills. We offer you to learn about the stages of manufacturing a round and rectangular table, coffee table and models for garden gazebo.

Making a wooden round table

It is easiest to make a round table top and a binder ring from either 1500 × 1500 mm and 1280 × 1280 mm. You will also need two strips of chipboard (1110 × 120 × 25 mm). We will make the legs from four wooden bars measuring 120 × 50 × 750 mm.

How to make a tabletop

How to draw a circle perfectly even? On a sheet of plywood in the center place their own thumb hands with a string attached to it with a pencil. The length of the rope from the base to the top should match the radius of the future tabletop. Holding your finger in one place, draw a circle with a pencil around the full length of the rope. It remains to cut it with a jigsaw.

The circle-underframe is cut out in a similar way.

Leg manufacturing

A round table made of wood or chipboard will look charming if done consistently. You don’t have to mess with the legs if there is no excessive originality in the plans. The bars are divided into 4 parts according to the desired table height minus the thickness of the tabletop. First, one leg is cut off, and the other three are already aligned along it.

All processing grinder carried out immediately.

Advice! Sanding should not be rushed, as the first coating with varnish will give out all the shortcomings.

Assembly of the structure and processing of the finished product

Assembly is carried out in stages. First, the strips are aligned groove into groove. Then the crosspiece of the slats is connected with the legs with confirmations, as in the figure below:

If you want to make the structure stronger, before connecting the legs to the tabletop, their upper base is smeared with glue.

Advice! Nails are not used in such work: a self-tapping screw or confirmation can be unscrewed without problems, and the connections will be much stronger.

Making a rectangular wooden kitchen table

The rectangular design is classic and very useful in everyday life: it is convenient to cook on such a table and you can comfortably dine at it.

How to make a tabletop

The tabletop made of wood for the table is made either from a whole sheet of plywood, or from individual edged boards processed to perfect smoothness.

Having fastened the boards with screws and glue, they begin to manufacture the frame.

Production of wooden legs for the table and frame

At the heart of quadrangular models is a frame. It serves to securely fix the legs, ensuring the stability of the entire structure. The tabletop is turned over, measured 3-4 cm deep on each side and the measurements are transferred to the boards. As a result, you will need two boards of smaller length and two larger ones.

The frame is made of four elements: according to the approximate ratio, these are two boards of X cm and two of 2X cm. They are overlapped with each other in turn, building a rectangle. In order not to break the angle of 90 °, any board is used while working with a screwdriver: they press the structure with it while tightening the screws.

As soon as the frame box is ready, they begin to make legs. You can take ready-made balusters for the table, buy metal supports, or cut them out of bars according to the desired length according to the drawing.

Both the frame and the legs are subject to obligatory thorough polishing!

Product assembly and finishing

The frame is screwed to the countertop with glue or self-tapping screws. Then the product is turned over and the legs begin to be attached.

Important! It is better to make holes for the screws in advance. This eliminates the possibility of splitting the tree.

Why not use nails and a hammer? Not everyone has the skills to work with a hammer - here it is dangerous not only to hit your finger. From excessive zeal, it is easy to damage the wood by splitting it. Confirmates and self-tapping screws hold the tree much stronger.

As soon as the leg is fixed, the angle is immediately checked: there should not be any deviation from 90 °. The operation is repeated with other legs. You can attach the legs directly through the countertop, but this will affect the aesthetic component of the product.

Related article:

: a photo best ideas. What can be done from a pallet for an apartment, office and cottage; rules for the selection and processing of pallets; master classes on making a table, sofa, bench, armchair and shelving - read in our publication.

Making your own wood coffee table

Not only a beautiful element of the interior, but also useful. No need to look for where to put a book, gadget, glasses, TV remote control in a conspicuous place. Such necessary designs are made from different materials: metal, glass, plastic, chipboard, wood. But let's leave other materials alone and concentrate on working with wood.

Choice wooden tabletop for the table depends on the expectation of the owner of the product. Someone wants something massive, while someone prefers lighter options. Let's go with a simple solution.

We buy five boards 30 × 150 mm and process them to perfect smoothness. We immediately saw off the desired length on the countertop: you should get 6 identical canvases. We take four bars on the legs, 6 canvases of shorter length on the lower tabletop, 4 narrow slats for the frame.

| Illustration | Action Description |

|---|---|

| For brushing wood, use a grinder with a brass brush head. The procedure will expose the structure of the tree, giving the product a special flavor. |

| We pass back and forth on each board from the side that will be the front. |

| We process wood with fire. The flame is gradually moved from place to place: the board will acquire a beautiful darkish tint. The procedure will finally destroy unnecessary soft wood fibers. We actively wipe the entire surface with a felt boot or a piece of felt. |

We proceed to the process of assembling a small table with our own hands from wood.

- The bottom and top tabletops are laid on the work surface with the wrong side facing you. The boards are laid tightly to each other, gluing them together. As soon as the boards grab, slats are attached to the top tabletop. They will serve as a frame and a fastening element. They can be glued or screwed with screws. The self-tapping screw is screwed in the center of the rail into each of the boards.

- The legs are screwed to both the table top and the rails. You can use furniture corners.

Video: the process of making a wooden coffee table

Making your own wooden table with benches in the gazebo

It's time to take the time and build a garden wooden table.

It is best to take boards of standard sizes. Studs are purchased at a hardware store (suitable with a length of 16 cm), washers (24 pieces). Long nails (8 cm) will fit for a garden gazebo.

To paint a product or just varnish it is already a matter of taste.

Regardless of the size of the kitchen, whether it is a spacious kitchen in a new building, country house or a small one in a small family, the most important piece of furniture is the kitchen table. For the production of tables today are used different Construction Materials e.g. glass, metal, stone, plastic, wood. But of all these materials, wood is still used more often. If you want to save money, then the kitchen table can be made independently. In this scenario, you can save up to 70% of the cost of the table. But first you should work hard and take into account a large number of factors that we will consider together with you in this article.

Making important measurements and calculations

Before starting work on the manufacture of the kitchen table, it is important to make some calculations. Usually such tables are calculated for a specific number of people. As a rule, this number ranges from three to nine. But it is best to take into account a couple of extra places in the calculations, in case guests arrive. If you are hospitable hosts, then most likely you will need a large table that can accommodate up to fifteen people.

Important calculations:

- The working length for one person should be 60 cm. This figure is multiplied by the number of people. The resulting figure will be the perimeter of the future table.

- How exactly the table will be installed: in the middle of the kitchen, near the wall. In the first version, the table will be able to accommodate more guests.

- Will the table have drawers or other accessories.

Decide on the size and location. Optimal width the table is considered 80–110 cm. If a narrower table is planned, then you will have difficulty serving. In the case of choosing an oval table shape, it is necessary to calculate the circumference. To do this, multiply the square of the radius by the number Pi (3.14).

Round or oval kitchen tables are necessarily located only in the center of the kitchen.

- Do not place the table near the stove.

- You can not put a table under the air conditioner.

It is equally important to decide on the shape of the table. Surface geometry can drastically change the look of an entire space. It directly depends on the shape whether it will be convenient to eat or not. Most of all, a rectangular shape with right angles is in demand. These countertops are great for square or rectangular kitchens. At the same time, it can be placed near the wall or in the center of the room.

Oval-shaped tables are also very popular. There are several valid reasons:

- The oval table has an attractive appearance.

- There is no need to go around corners. This is especially convenient when there are small children in the house.

- An oval table is best suited for a formal meal.

There are a lot of advantages in favor of an oval shaped kitchen table. But in the presence of a large family, it is inferior to a rectangular shape. There are also round shapes, but with this option it will be inconvenient to take certain dishes. As for the oval table top, the ideal diameter is 140 cm.

So, when choosing the shape of the table, start mainly from your own taste. Moreover, remember that for a kitchen of 8 m 2 or less, an oval table will be impractical, as it will require a lot of free space.

We prepare drawings and tools

If you have decided on the size and shape of the kitchen table, then you can proceed to the next step - drawing up a drawing. It should display the required dimensions of the surface, legs and other elements. You should consider the method of fastening certain nodes. Consider, for example, a kitchen table that will have the following dimensions: 120x60x75.

Although such a table will be small, you can easily understand the principle of making such furniture using its example. In your drawing, you can resize the table according to your needs.

You will need:

- Tabletop 1.2 × 0.6 m - 1 piece.

- Cross jumpers 40 × 2.5 cm - 2 pieces.

- Longitudinal jumpers 100 × 2.5 cm - 2 pieces.

- Table legs 70 cm high - 4 pieces.

To build a countertop, you need to prepare boards of the appropriate size. Before starting work, you will need to consider the method of attaching important nodes.

First of all, you need to collect all essential tool and materials:

- plane,

- hacksaw,

- electric jigsaw,

- screwdriver,

- sandpaper,

- ruler or tape measure

- square,

- pencil,

- circular saw,

- milling machine,

- file,

- clamps,

- paint brush,

- wood glue,

- polyurethane varnish: matt or glossy,

- solvent.

When everything is ready, you can get to work.

Assembly Guide: Countertop Requirements

As for the countertop, it is important to decide whether it will be sliding or not. For example, when assembled, the table can be used for cooking, and in a sliding state as a means for eating.

The countertop should not absorb odors and grease. Also consider practicality.

A good countertop should not absorb moisture, withstand strong impacts. The surface of the table should not be afraid of steam, condensate and high temperature. All these requirements are met by a countertop made of natural and artificial stone or covered with ceramic tiles. But it should be noted that such a table will look only in the interior of modern style.

One of the most common types of countertops is chipboard, laminated with film or covered with plastic. At the price of chipboard plates are available to many. Moreover, such material is the easiest to work with. Some may deny that chipboard countertops are practical. This is partly true, but with proper processing, it will last more than one year. Here are some recommendations and tips for working with chipboard countertops:

- The film or plastic should be rounded at the ends of the chipboard.

- Each 90° rounded end is treated with silicone.

- However, in this position, the end is vulnerable to moisture ingress, so it is better to wrap the end 180 °.

You should be objective and mention the disadvantages of such a countertop. If the chipboard swells, then there is no way to fix this problem. As a result, you will have to make a new table or at least a countertop. But, on the other hand, such a surface is resistant to aggressive detergents and to mechanical influences.

Of course, if we talk about the most ideal and environmentally friendly option, then here the tree rightfully comes first. But in the care of such a surface is more capricious. Do not allow moisture to penetrate into the wood, allow scratches and other damage. Microbes can settle and multiply inside them, which adversely affect the mechanical strength of wood. Therefore, from time to time, wood countertops must be varnished, cleaned, and opened with a layer of wax.

leg requirements

The number of legs will vary depending on the shape and size of the table. For example, if you are making a table from chipboard, then 4 legs will be enough, which are attached to the corners of the tabletop. If you make strong wooden legs, then this design will be durable and strong.

Legs can be made by hand. To do this, you can purchase a ready-made sketch. The complexity of this work will depend entirely on the shape of the legs. If you think that this is beyond your power, then purchase ready-made metal legs or choose carved wooden ones. Everything will depend on your financial capabilities.

The table can be on one leg. As mentioned above, this will depend directly on the weight, shape and configuration of the countertop and the table as a whole.

The table, which has one massive leg, looks impressive and beautiful from the side. For its installation, a high-quality cruciform strapping is performed.

Two massive legs are located at a certain distance from each other. In most cases, a table with two legs is rectangular or oval. The advantage of such structures is that the legs will not interfere with any of the sitting people. As for the design of such legs, they expand at the bottom to increase the area of \u200b\u200bsupport. Between themselves, they are connected by a jumper board.

But ordinary tables with four legs are simple in design and do not need precise and complex calculations. This table is stable and durable. The most important thing here is to choose the right size of the legs and mount them at the right distance. At the same time, tables on four legs can be very different in shape: oval, round, square, rectangular.

So, regardless of the number of legs chosen in your design, their aesthetics always remain the most important. Aesthetic appeal table legs are more important than even the beauty of the tabletop. After all, the tabletop is always covered with a tablecloth or oilcloth, and the legs are always visible.

We build a folding table

One of the simple shapes of the kitchen table is rectangular. This design consists of four legs and six sidewalls of the box. The table top and sidewalls can be made from 18 mm chipboard, and the legs from a 40 × 40 mm bar. First you need to make plywood drawers, 2 cm thick (table legs will be attached to them), as well as two horizontal strips. It is on them that the removable part of the table will be placed. In our case, for the manufacture you will need to purchase the following material:

- Self-tapping screws 4×16.

- Self-tapping screws 4×50.

- Furniture corners 30×30.

- Laminated edges in the color of chipboard.

- Wooden dowels 8×40.

To make the table move apart, you can use standard guides. They provide smooth movement of the countertop. So, all the necessary parts of the following sizes are pre-made:

- Leg 710 mm.

- Two fixed parts 450×700 mm.

- Removable part 400×700 mm.

- For the box of the fixed part, there are four sidewalls 420 × 120 mm.

- For the box for fixed parts, two end 600 × 120 mm.

- From plywood, two side drawers 830 × 120 mm.

- From plywood, two end sides 498 × 120 mm.

- To accommodate a removable tabletop, two strips 498 × 120 mm.

With such blanks, you get a sliding table in size:

- Extended 1300×700 mm.

- Assembled 900×700 mm.

It is best to cut all the blanks on special equipment. This is important in order to accurately withstand all dimensions. All blanks made of plywood and wood should be carefully cleaned and varnished in two layers.

So, step by step instructions:

- First of all, the side and longitudinal drawers are fixed on the outside of the legs flush with the ends. After that, with the help of self-tapping screws 4 × 50 mm, corners are attached from the outside and from the inside 4 × 16 mm. The corners are attached to the longitudinal tsargs through horizontal slats.

- Further, a wide guide is fixed on the inside of the side tsarga.

- Under the dowels, you will need to drill two holes on the inner ends of the countertop. They are attached for a collapsible connection, that is, one half will be free, and the second will be attached to the glue. From the dowel to the edge of the countertop, the distance should be equal, but not exceed 10 cm.

- Two dowels are mounted on a removable tabletop. To do this, two holes are drilled on the reverse side.

- At the next stage, it's time to assemble the U-shaped parts of the box from chipboard. In this case, the end elements 600 × 120 should be located between the sidewalls 420 × 120 mm.

- Now screw on the narrow guides. This is necessary so that the chipboard box moves on average 2 mm higher than the plywood collet.

- After that, the guides snap into place and are checked for movement along the drawer.

- Attach the non-removable part of the tabletop using corners and 4x16mm self-tapping screws. Both parts must match perfectly. Therefore, just before attaching them, slide both parts and check their alignment. Then carefully push the drawers apart and secure the countertops.

- On the shelf inside the table, place the removable part of the table top.

Folding table - an original solution for a small kitchen!

If your kitchen is miniature, then choose suitable shape the kitchen table is not easy. However, there is always a way out. For example, you can build a homemade folding table. When folded, it will serve as a decorative frame, and when unfolded, it will serve as a full-fledged dining table. Although in each case the size of such a table will be different, we will take our sizes as a basis. This will allow you to visualize what exactly your drawing will look like.

For work you need:

- MDF board 180 mm thick - 5 pieces,

- 150×90 cm,

- 130 × 10 cm - 2 pieces,

- 90×20 cm,

- 70×20 cm,

- holdfast,

- wood glue,

- acrylic putty,

- electric drill,

- drill for wood 3 mm and for metal 8-10 mm,

- sandpaper,

- acrylic paint for wood

- roller,

- masking tape,

- screws 3.5×30 and 3.5×16 mm,

- loops,

- screwdriver,

- two furniture bolts.

The whole process of work will not take you much time if you strictly follow the step-by-step instructions below.

- Based on the set of material, the table will be made of MDF. Make drawings first.

- The frame is built first. To do this, four smaller elements are attached to the largest board from below, using a carpentry vise. Every 250 mm, holes are drilled in the frame with a Ø3 mm drill, up to 3 cm deep.

- After that, a hole is drilled with a metal drill Ø8-10 mm to a depth of 3 mm. In this way, it will be possible to deepen the heads of the twisted screws.

- Further, carpentry glue is applied to the lower surface of the four frame elements, and after that, each element is applied in its place. Each of them must be well pressed with a carpenter's vice.

- Mounting the frame on glue is not enough, so you should additionally fix it on screws.

- At the same time, disguise the screw heads so that they do not spoil the overall look. To do this, you will need acrylic putty.

- When the putty has dried, you can sand the surface of the decorative frame with sandpaper.

- The ends of the countertops should be glued with masking tape.

- Paint the surface of the frame acrylic paint using a roller, and paint over the corners and edges with a brush.

- Then screw the hinges along the short edge of the table top. From the edge must be at least 150 mm. Mark holes on the wall and drill for the dowel. Thus, the hinges will be screwed to the wall.

- When the table is in an upright position, it will be held on top with latches. They should be fixed in such a way that they are not conspicuous, for example, at the edges of wall shelves.

Table from postforming table top in 5 steps

Such a table can be completed in the shortest possible time. To do this, you will need to first collect all necessary material and tool. You will need:

- pencil,

- postforming tabletop,

- jigsaw,

- jigsaw file,

- Sander,

- edging,

- cutter,

- silicone sealant,

- rubber mallet,

- sharp knife,

- clamps,

- metal legs with holder

- hex key.

All work can be done in 5 successive stages.

Stage 1

On the front side countertops, mark with a pencil. The markup will match your drawing. Each rounding is performed with a radius of at least 60 mm. This will prevent the edge from discoloring at sharp bends.

Stage 2

Now you need to give the appropriate shape to the countertop. To do this, use a jigsaw. When cutting, it is recommended to leave a small backlog of 2-3 mm. Pay attention to the direction of the jigsaw blade. It must have a reverse direction of the teeth. This will avoid chips on the plastic coating. Although partially they can be hidden by piping. To accurately bring the dimensions and shape of the countertop, you need to work on the ends grinder tape type.

Stage 3

In the third step, it's time to mill the groove. Milling is always performed strictly in the center of the end face. And this is even regardless of whether the edging will exactly match the thickness of the table top or will be large. If you do not have a cutter with exact dimensions edge groove, then you can walk several times with a cutter with a lower tooth height.

Stage 4

When the groove is ready, you can start stuffing the edging. To do this, the end face is pre-coated silicone sealant. This will prevent water intrusion. Sealant is applied to the top edge of the edge. The edge itself is stuffed with a rubber mallet. The joint should be formed in the most inconspicuous place. When the stuffing is completed, it is important to make an exact docking of the piping. Here you can't do without sharp knife. After that, you will need to remove the excess sealant around the entire perimeter of the countertop, which was formed when the edging was driven in.

When fixing countertops using clamps, it is important to use special gaskets. They are installed on the protruding edges of the edge and prevent their damage.

Stage 5

At the final stage, the legs are fixed. To do this, you should attach the molded holders to the underside of the tabletop. So that they are at the same distance, mark up with a pencil. From the edge of the leg should be at a distance of up to 10 cm. This holder is fixed with self-tapping screws 2.5 cm long with a countersunk head. Now it remains to make the final touch: fix the legs in the holder with a hex wrench. The dining table for the kitchen is ready!

As you can see, the table from the postforming tabletop is very simple and, most importantly, available for home-made manufacturing at home. To do this, you need to have basic carpentry tools. But there are also dangers to be aware of here. If handled carelessly, there is a risk of breaking the holder, which is made of fragile material. But if you carefully operate such a table, it will last for many years.

The choice is yours

We have considered with you several options for how to make a kitchen table. There are other technologies for its manufacture. In most cases, everything will depend only on your financial capabilities and ingenuity.

Video

This video shows an example of making a rectangular kitchen table with rounded corners. Balusters are skillfully used as legs: